Blog/News

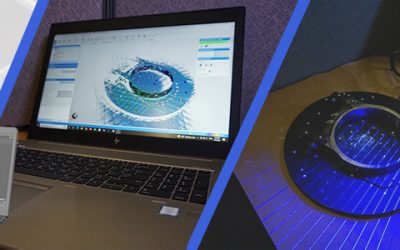

3D Scanning, Reverse Engineering, & Rapid PrototypingKeep up With Industrial Competition: Adopting 3D Scanning Technology

3D scanning is a hot new technology that will change the way we do business forever. It has been employed in everything from measuring and surveying, quality control for industrial companies or even designing products! There are so many ways you can use 3d scanners to...

7 Examples of 3D Printing in the World Today

3D printing has become an extremely disruptive force in the manufacturing world, and many refer to it as the manufacturing solution of the future. The automotive and aeronautical industries, to name a couple, have experienced the benefits of 3D printing technologies...

Automotive Prototypes – Large-Scale & High Accuracy

The automotive industry has found a way to benefit from 3D printing by using it in the production of hundreds high quality, tailor-made and highly customized parts and products. In this quick project, we demonstrated how we produced a 3D printed a bellhousing...

Producing Electronic Enclosures on Industrial 3D Printers

3D Printing plays a big role in the development process of electronics and computers.Design Quality of Hardware for Electronics One of our clients wanted to print a CPU enclosure on their consumer 3D printer at home, but the results were not good due to warping and...

Creaform Kickstarting Quality Control Processes on Italian Hypercars using 3D Scanning

Built to perfection, Pagani Automobili combines beauty and attention to detail with the best racing technology.At first, an unusual feeling of quietude rests on the racetrack, but this temporary peace is just asking to be disturbed. Leaning against the railing, you...

Expanding Markforged Versatility – Smooth TPU 95A

Markforged has launched a brand-new type of thermoplastic polymer called Smooth TPU 95A. This flexible and functional part can be used for things like drive belts or protective coverings plus more!The global supply chain has been struggling with the production of...

eBook Download – Future of 3D Design & Manufacturing

There's never been a better time to utilize such innovative and advanced tools for companies that have any manufacturing processes involved in their business.It has been proven that 3D Scanning and 3D Printing technologies in combination can not only generate more...

How to Smooth Your 3D Prints in 6 Simple Steps

3D prints typically all come out showing a hint of layer lines, but now a totally smooth surface finish is possible with the introductions of acetone 3D print smoothing. What is it? One of the many things that fused deposition modeling (FDM) 3D printers lack is a...