Enhancing Manufacturing and Product Development Methods

In the ever-evolving landscape of industrial manufacturing, precision and accuracy reign supreme. Oqton, a trailblazing 3D software provider, has harnessed the power of reverse engineering and 3D scanners to revolutionize industrial product development, streamline quality control processes, and detect defects with unprecedented precision.

Easily generate scan data!

3D Scanning

1. Streamlining Prototyping:

- Our solutions employ Creaform 3D scanners to capture intricate details of prototypes, enabling rapid digitization of physical objects into precise 3D models.

- The digitized models serve as blueprints, expediting the design iteration process and reducing time-to-market for new products.

2. Accurate Geometric Analysis:

- Creaform scanners ensure high-resolution scans, facilitating comprehensive geometric analysis of complex shapes and structures.

- Engineers leverage these analyses to fine-tune designs, ensuring products meet exacting specifications.

Reverse Engineering

1. Capturing Existing Components:

- Creaform scanners are also used to capture 3D data of existing components or products, even those lacking digital design files.

- The reverse engineering process using Geomagic Design X empowers manufacturers to recreate parts with precision, aiding in maintenance, replacement, and redesign efforts.

2. Innovating with Legacy Components:

- Legacy components are seamlessly integrated into modern designs, thanks to the accurate scans provided by Creaform technology.

- Manufacturers leverage this capability to extend the lifespan of existing components while embracing new design enhancements.

Computer-Aided Inspection

Detecting Inaccuracies and Defects:

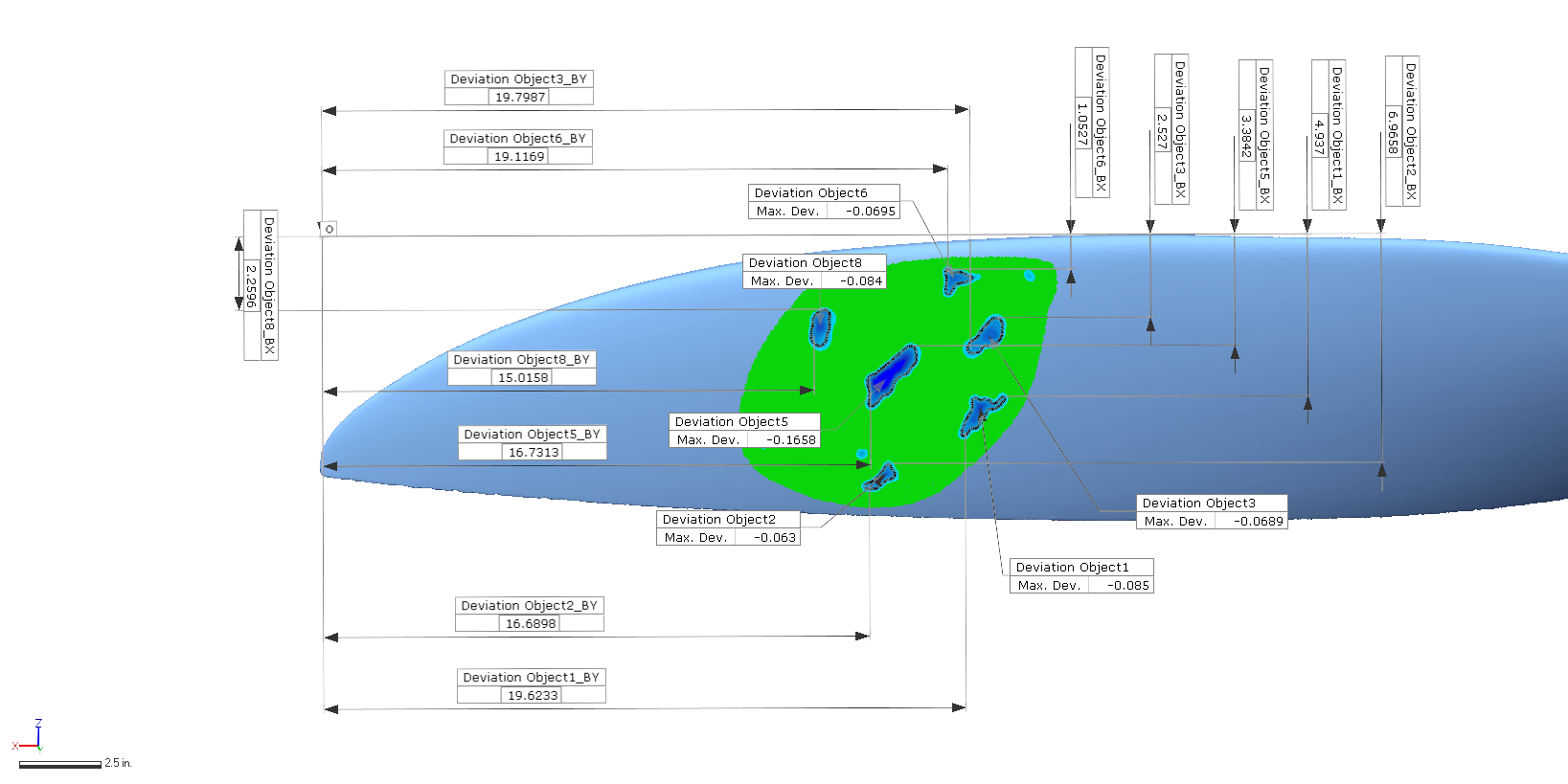

1. Precise Inspection:

- Creaform 3D scanners enable non-contact, high-precision inspections of manufactured components.

- NeoMetrix employs these scanners to compare scanned components against CAD models, detecting even the slightest deviations.

2. Comprehensive Defect Detection:

- Defects, imperfections, and deviations are identified through meticulous scans, ensuring compliance with stringent quality standards.

- From automotive to aerospace industries, Creaform scanners provide the accuracy required to maintain optimal product quality.

3. Efficient Rejection Prevention:

- Manufacturers prevent costly rejections by addressing defects in real-time during the production process.

- This proactive approach minimizes waste, maintains production efficiency, and safeguards overall product integrity.

NeoMetrix’s strategic collaboration with Oqton has unlocked a new era of precision, efficiency, and innovation in industrial product development and quality control. By harnessing the unparalleled capabilities of Creaform 3D scanners, NeoMetrix has demonstrated how technology can seamlessly integrate into manufacturing workflows to elevate both the design and production processes. As industries continue to evolve, NeoMetrix and Creaform stand at the forefront, empowering manufacturers to push boundaries and redefine the benchmarks of excellence.

Industrial Applications in Action

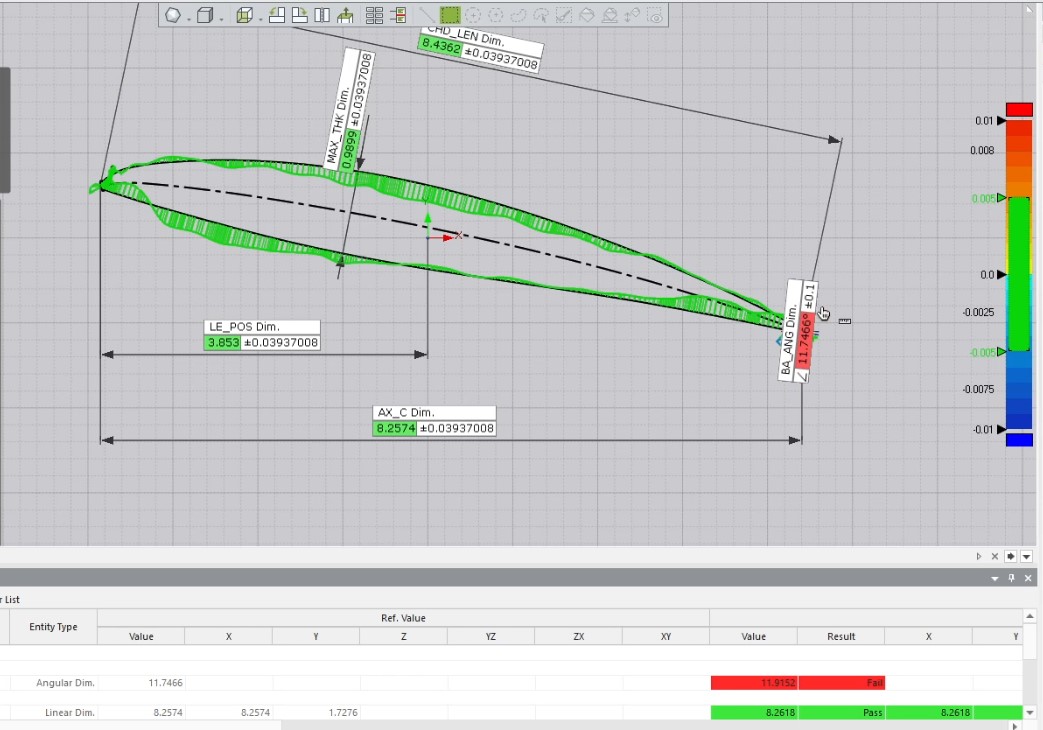

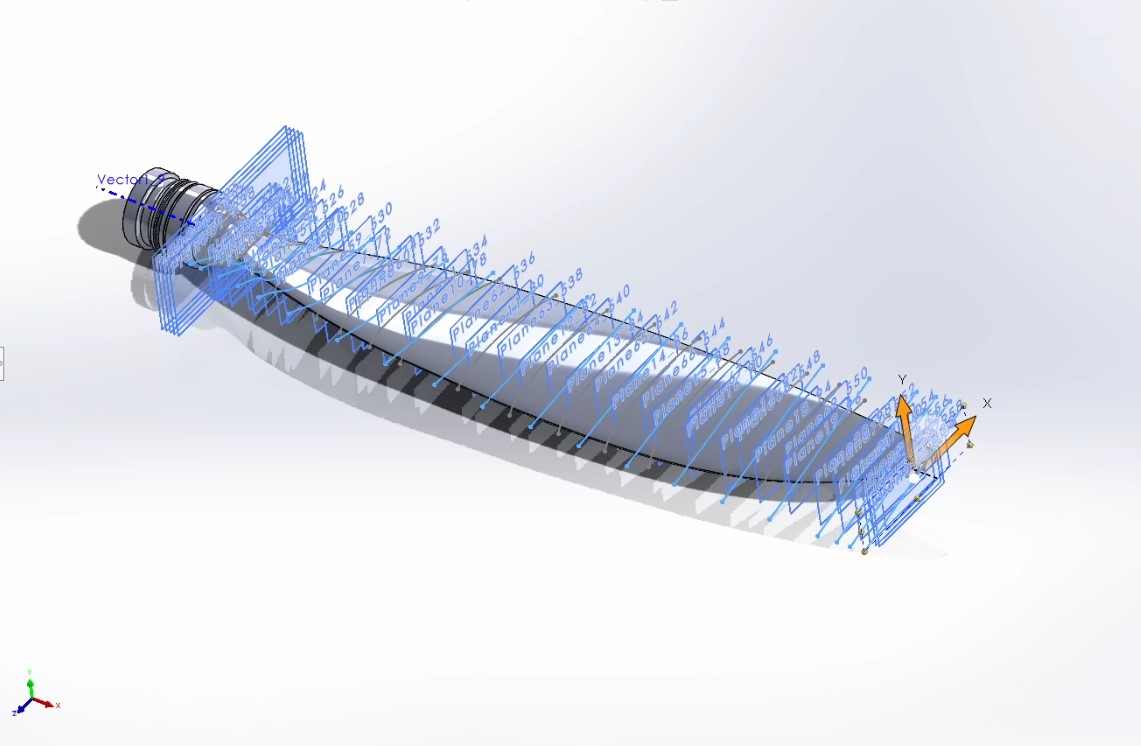

AEROSPACE

Advancing Aerospace Maintenance: NeoMetrix Technologies Digitizes Helicopter Blades

AUTOMOTIVE

3D Scanning and Rapid Surfacing for Aftermarket Product Development

CREATIVE

Creating Custom Jewelry using 3D Scanning – Art & Sculpture