Across industries like Aerospace & Defense, Automotive, Medical, and Industrial Manufacturing, reverse engineering allows teams to:

-

Rebuild obsolete or legacy parts without existing CAD data

-

Ensure precision fit and function across assemblies

-

Speed up product development with real-world geometries

-

Validate components through computer-aided inspection and quality control

When time, accuracy, and performance matter, companies turn to reverse engineering to keep production moving forward—fast and with confidence.

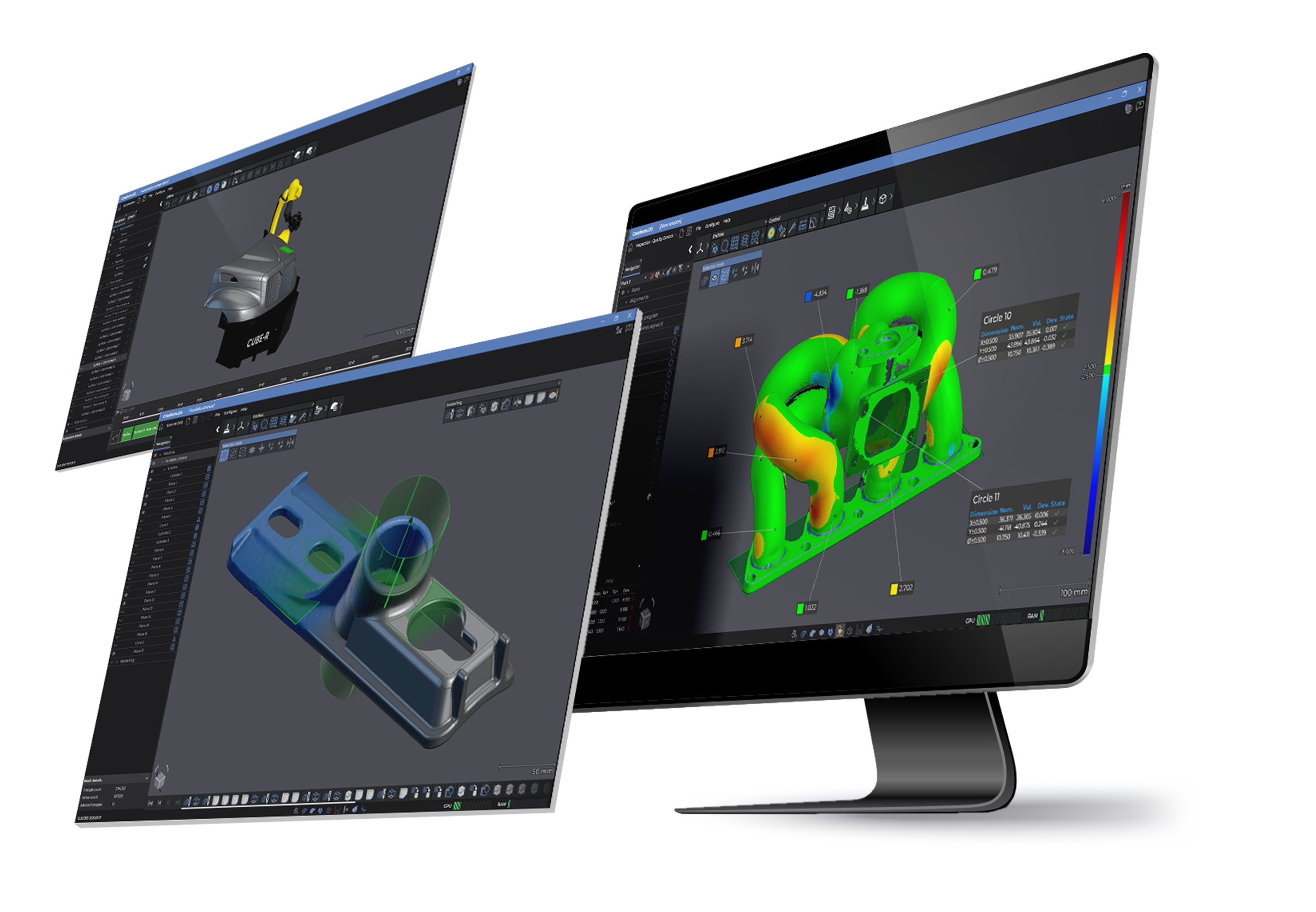

Powered by Industry-Leading Accuracy

At NeoMetrix Technologies, we leverage Creaform 3D Scanners, like the HandySCAN Black Elite, MetraSCAN Black Elite, and Go!SCAN Spark, to capture exact part geometry—down to microns. These scanners are known for:

High-resolution scanning on complex surfaces

Accuracy up to 0.025 mm in real-world environments

Fast data acquisition, even on large or reflective parts

This ensures engineers get a true-to-life 3D model that’s ready to use in CAD for inspection, design changes, or digital archiving.

Reverse Engineering with NeoMetrix

Whether you need a one-time service or want to bring 3D scanning in-house, NeoMetrix Technologies has the tools and expertise to make it happen. Our team supports businesses nationwide with the equipment, software, and engineering services to digitize your parts and deliver results that meet—and exceed.

Want more information?