Advancing Aerospace Maintenance: NeoMetrix Technologies Digitizes Helicopter Blades for Advanced Composite Structures

THE PROBLEM

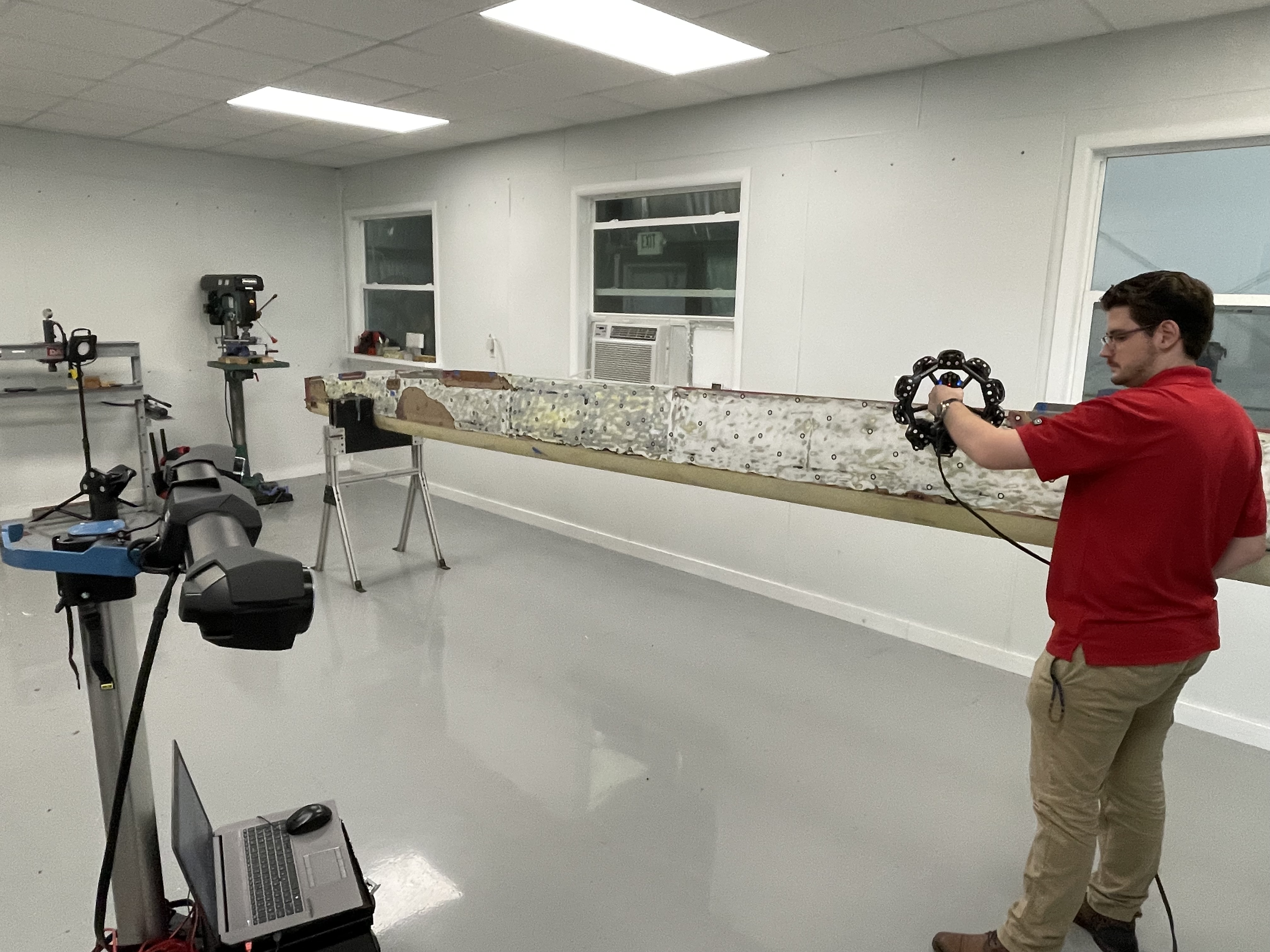

Advanced Composite Structures, an esteemed Aerospace company in Central Florida aimed to leverage cutting-edge 3D scanning technology to digitize helicopter blades, contributing to the extension of their operational lifespan. By utilizing the MetraSCAN Black Elite combined with the C-Track’s Volume Extension feature, our engineers successfully captured the entire blade in a single scan, ensuring precision and efficiency. The resulting feature-based model derived from these scans will play a pivotal role in creating drawings and manufacturing replacement parts for the blades.

TRADITIONAL METHOD

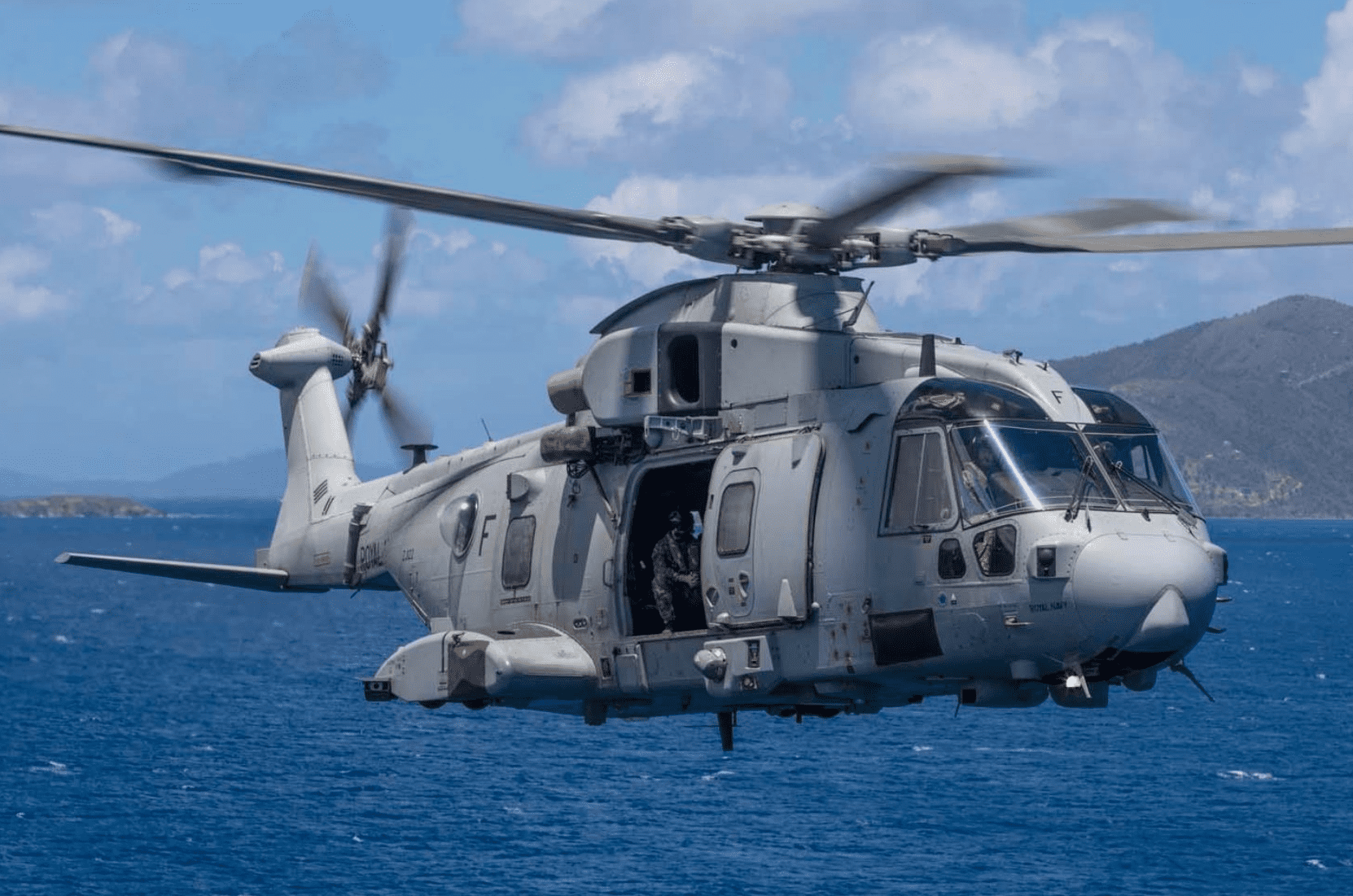

Helicopter blades endure rigorous usage and environmental stress, necessitating regular maintenance and periodic replacement. By employing 3D scanning technology, our engineers empowered Advanced Composite Structures to proactively address these challenges. The goal was to digitize the blades to create accurate models for better analysis, design, and manufacturing processes.

NEOMETRIX SOLUTION

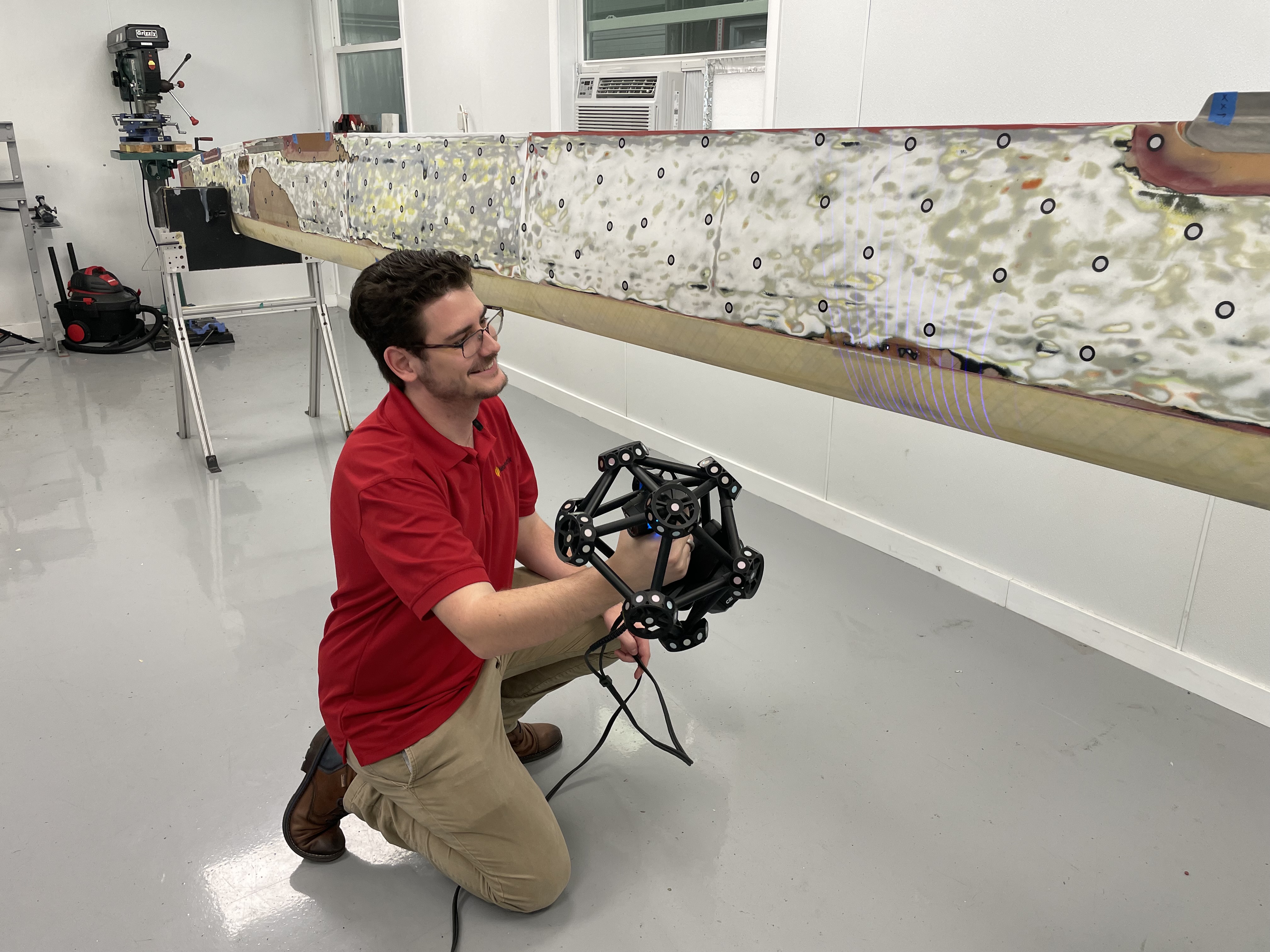

To achieve exceptional results, we utilized the MetraSCAN Black Elite, a state-of-the-art 3D scanning system renowned for its precision and versatility. This handheld scanner employs high-resolution blue laser technology, allowing for fast and accurate data acquisition. The MetraSCAN Black Elite’s portability and ease of use made it an ideal choice for scanning complex geometries such as helicopter blades.

In combination with the MetraSCAN Black Elite, we were able to leverage the C-Track’s Volume Extension feature. This extension increased the scanning volume, enabling the capture of the entire blade surface in a single scan. The extended scanning range drastically reduced the scanning time, while ensuring comprehensive coverage and minimizing potential errors.

Unprecedented Accuracy

During the scanning process, our engineers employed a scanning resolution of 0.10mm. This meticulous attention to detail ensured that the resulting surface data was captured with exceptional accuracy. The high-resolution scans provided a comprehensive representation of the blade’s intricate features, ensuring the fidelity of the subsequent modeling and manufacturing processes.

The Benefits of Feature-Based Modeling

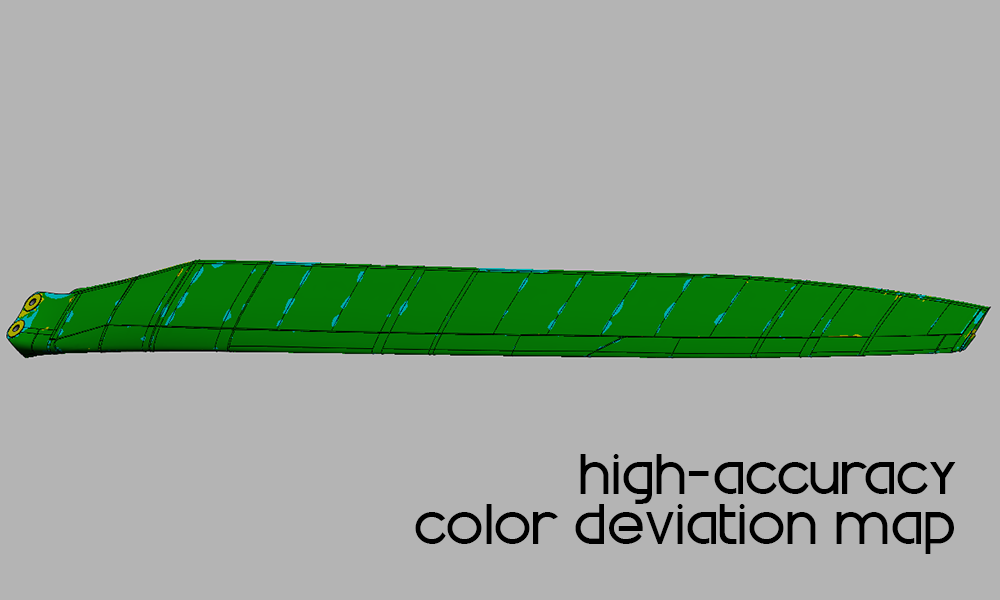

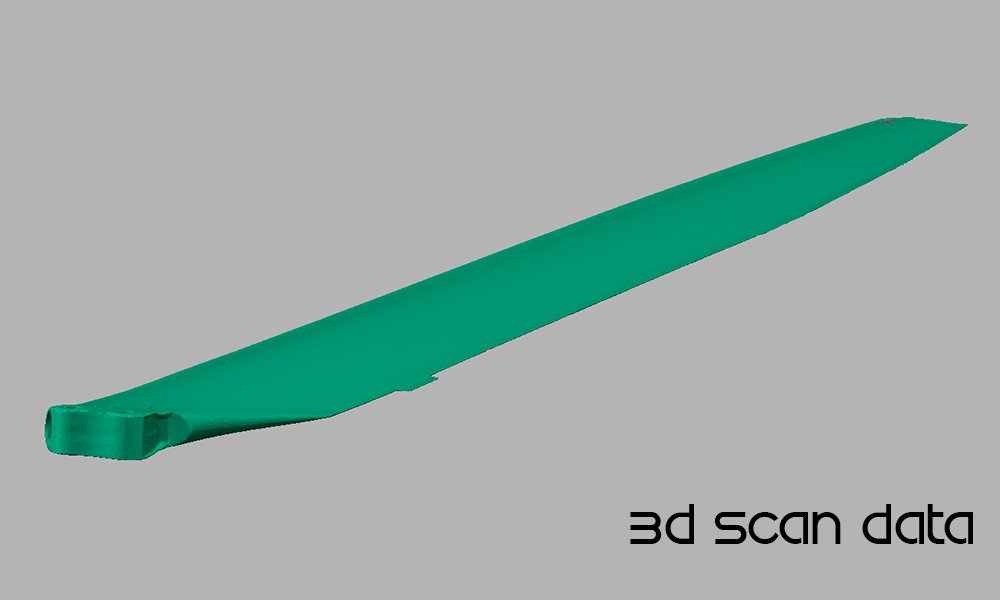

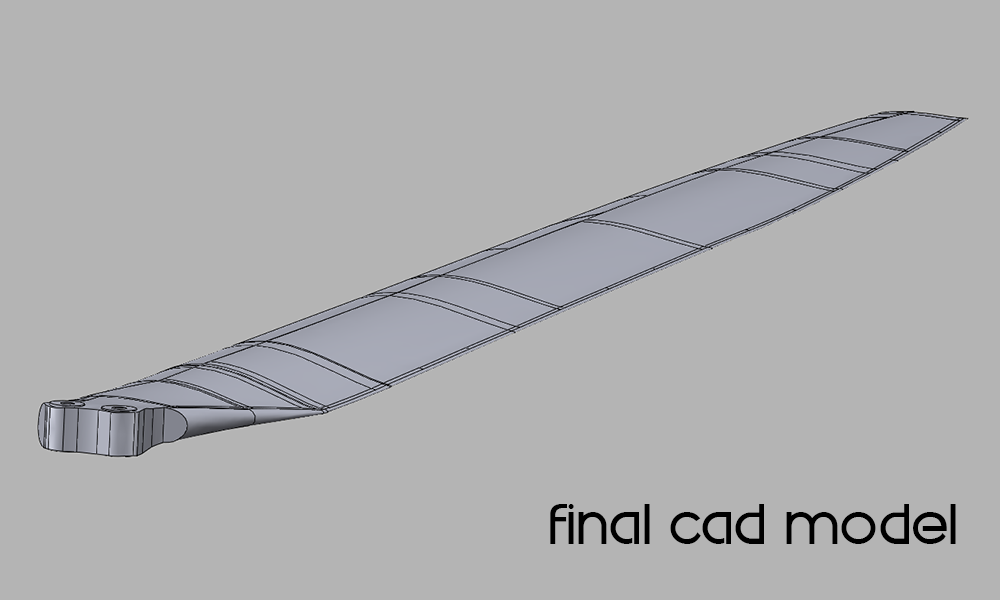

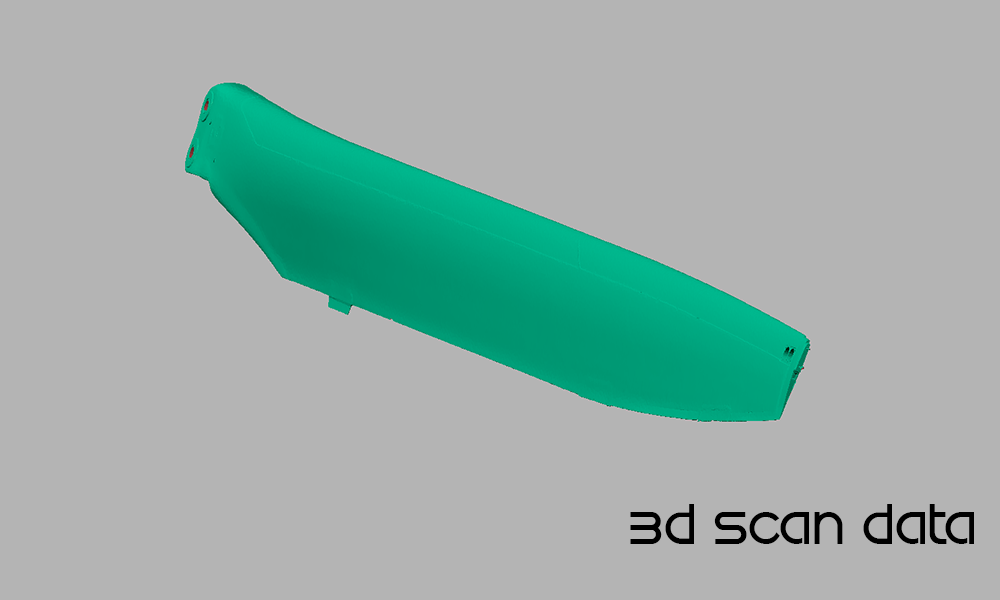

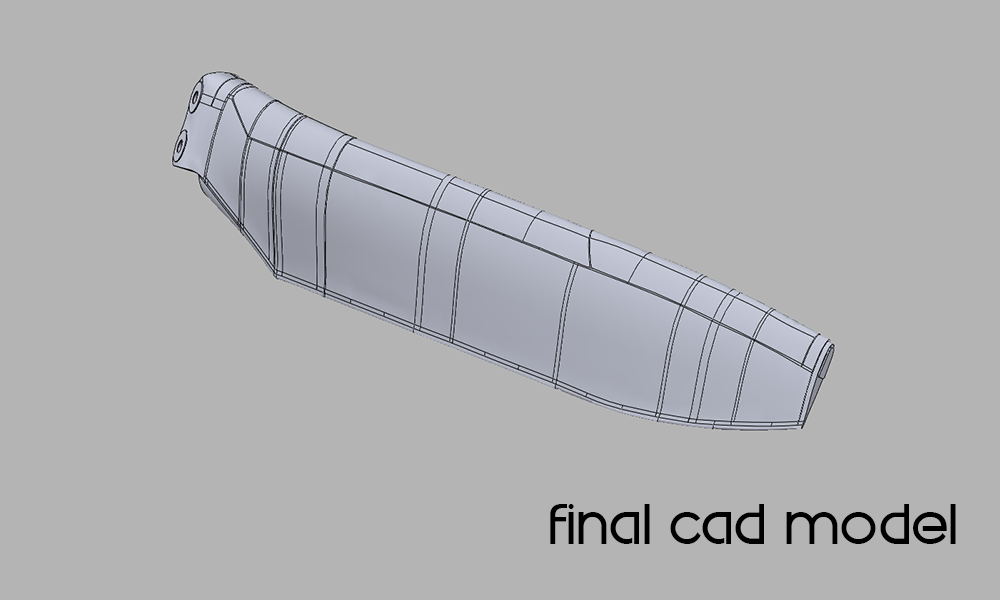

The feature-based model derived from the 3D scans serves as the foundation for various downstream applications. Advanced Composite Structures will utilize this model to create detailed drawings, facilitating precise analysis and design adjustments. Moreover, the feature-based model will expedite the manufacturing process by providing essential geometric information for the production of replacement parts. View the final scan data(colored) and CAD models(grey) below:

NEOMETRIX ADVANTAGE

Through the collaboration with Advanced Composite Structures, the 3D scanning of helicopter blades using the MetraSCAN Black Elite and C-Track’s Volume Extension feature has proven instrumental in prolonging the life of these critical aerospace components. By digitizing the blades and generating accurate feature-based models, Advanced Composite Structures gains valuable insights into blade performance, enables efficient maintenance, and streamlines the manufacturing of replacement parts. Our mission is to remain committed to pushing the boundaries of 3D Scanning technology to empower businesses in the aerospace industry and beyond.

For more information about our available solutions and services, please visit our website or contact us directly!

(888) 696-7226

Featured Equipment