Our solutions at NeoMetrix are a leading advocate for the transformative power of 3D scanning, paired with the sophisticated capabilities of Oqton software.

Gone are the days when 3D scanning was confined to hobbyist pursuits like scanning body parts and boats. Today, the demand for quick turnaround times, stringent tolerances, and the ability to measure complex shapes in extreme conditions has propelled 3D scanning into the realm of necessity.

Measure – Model – Inspect – Innovate

Consider the case of SCAN IT 3D, a trusted provider of 3D scanning services and a strategic partner of NeoMetrix. Operating in Germany and Switzerland, SCAN IT 3D‘s portfolio spans a myriad of projects, from reverse engineering vintage car parts to inspecting pipes and modeling heads. Within this diverse repertoire, two standout examples illustrate the indispensable role of 3D scanning in achieving feats previously deemed unattainable.

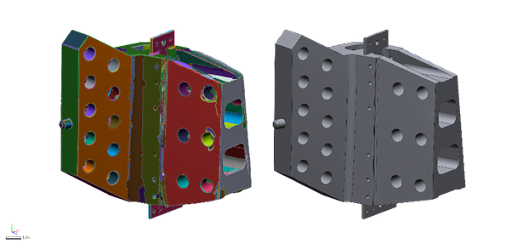

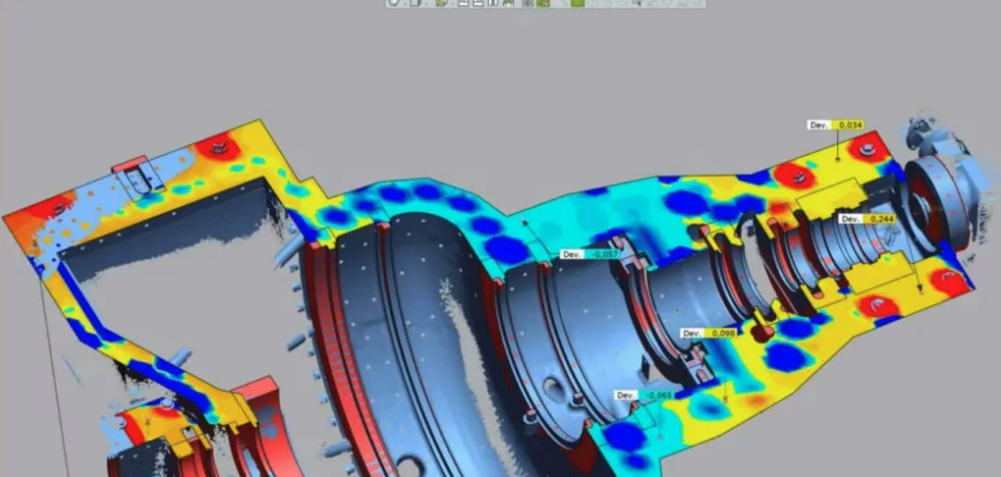

The inspection of a steam turbine, a colossal piece of machinery, exemplifies the practicality of 3D scanning in challenging scenarios. Traditionally, such inspections necessitated transporting the turbine to a specialized laboratory—a logistical nightmare. However, with the advent of portable and user-friendly 3D scanners like the Creaform, SCAN IT 3D could conduct on-site inspections with ease. By leveraging the capabilities of Geomagic Design X and Geomagic Control X, they efficiently reverse-engineered the turbine housing, ensuring precise measurements and identifying deviations in sealing surfaces. This seamless integration of hardware and software revolutionized the inspection process, offering unparalleled accuracy and efficiency.

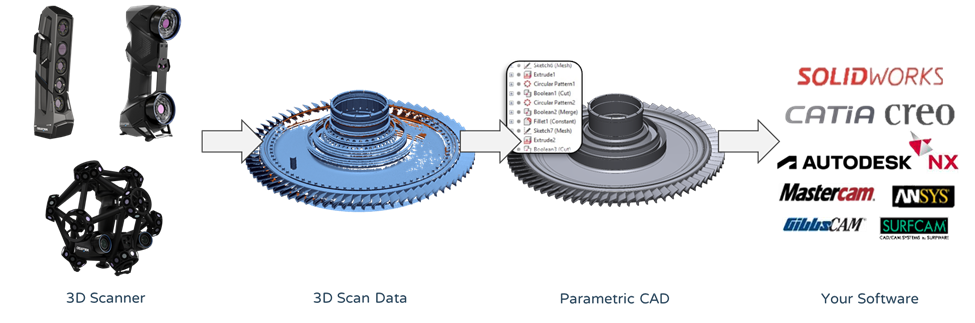

Geomagic Design X- An Engineers Favorite Software

3D Scanning and Reverse Engineering Demo

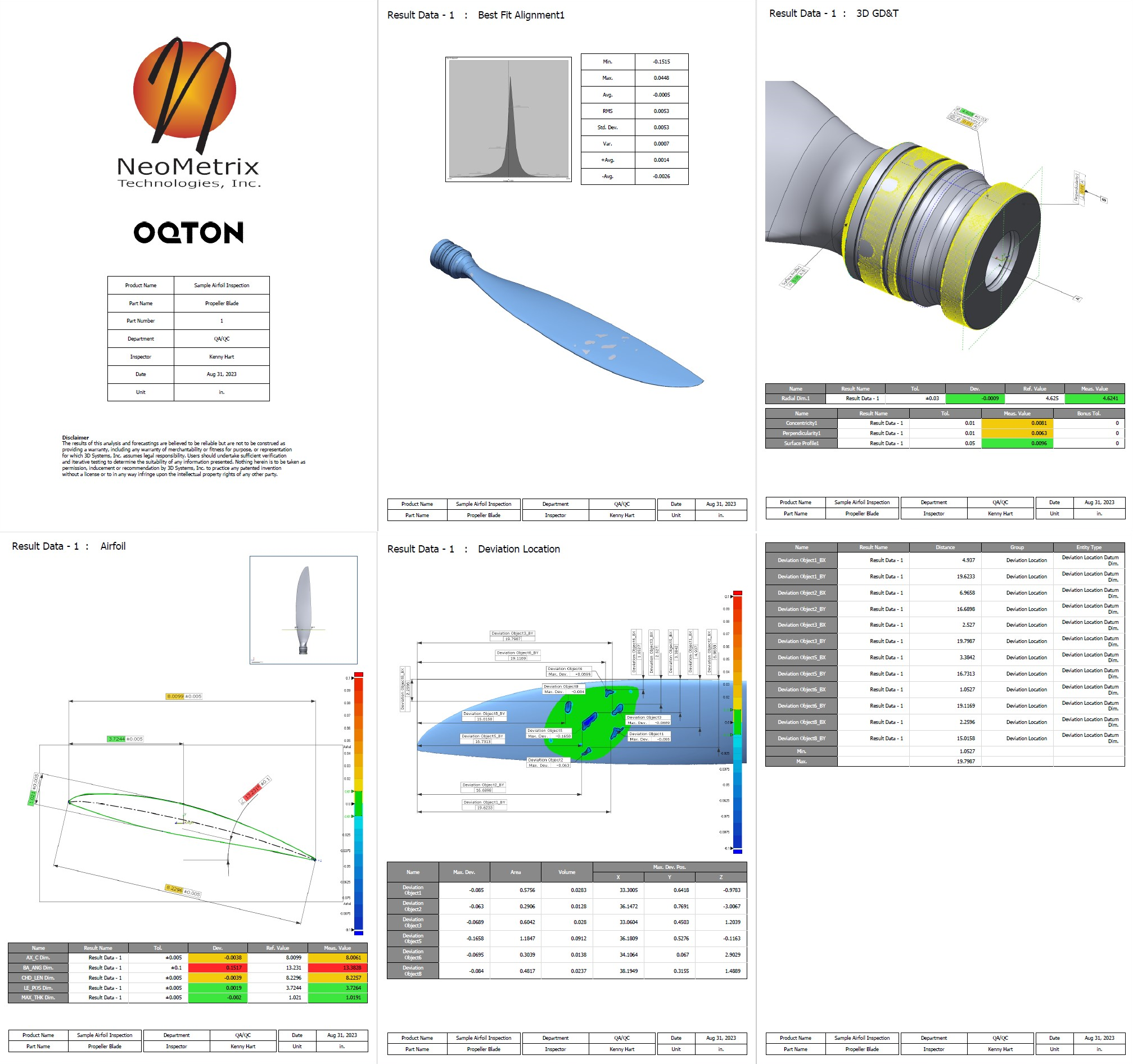

Similarly, the manufacturing of components like rocket nozzles demands meticulous attention to detail, particularly concerning wall thickness. Traditional tactile measuring methods prove cumbersome and inadequate in such instances. 3D scanning offers a non-contact solution that captures intricate details with unparalleled precision. SCAN IT 3D’s utilization of the Creaform scanner, coupled with Geomagic Control X, enabled real-time assessment of wall thickness deviations. Through vivid deviation color maps, areas of concern were identified, empowering manufacturers to maintain uniformity and quality throughout the production process.

The synergy between NeoMetrix’s expertise in 3D scanning and Oqton’s advanced software solutions has ushered in a new era of innovation and efficiency across industries. From aerospace to automotive, their collaborative efforts have redefined the boundaries of possibility, propelling businesses towards unprecedented heights of success.

As we navigate the ever-evolving landscape of manufacturing, the imperative for precision and repeatability has never been more pronounced. Embrace the future with NeoMetrix and Oqton, where what once seemed impossible becomes reality. Join our on-demand webinar to explore the transformative potential of 3D scanning and Oqton software. Seize this opportunity to revolutionize your industry and unlock new possibilities. Schedule your session today and embark on a journey towards precision and efficiency like never before.

Our Mission: To partner with our clients by understanding their unique requirements and aid in developing, deploying, and supporting effective solutions.

Go from 3D Scan-to-CAD faster than ever before!

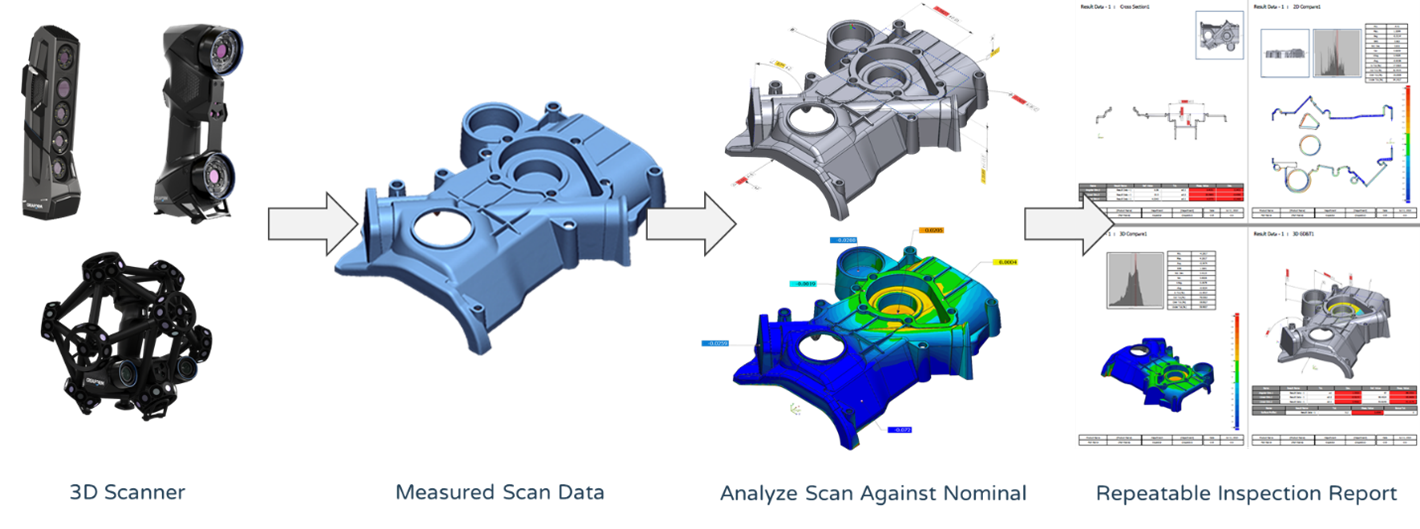

Generate Custom Reports!

STREAMLINE REAL WORLD APPLICATIONS

Advancing Aerospace Maintenance: Digitizing Helicopter Blades for Advanced Composite Structures

3D Scanning & Reverse Engineering an Aircraft