Mastery of Inspection: Ensuring Airworthiness and Safety

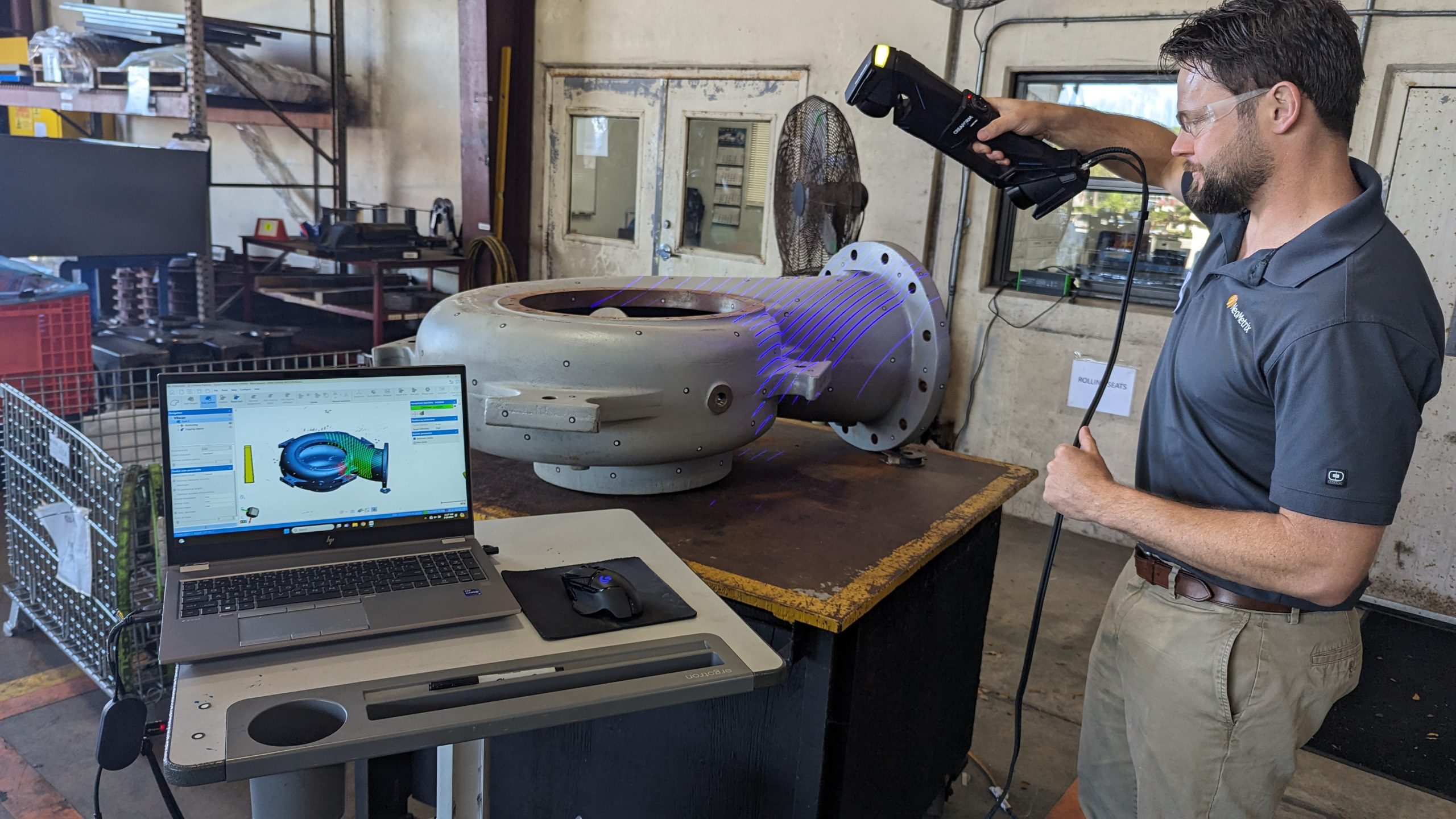

In aerospace, quality assurance is non-negotiable. NeoMetrix masters the art of inspection, ensuring airworthiness and safety with meticulous attention to detail. Utilizing state-of-the-art metrology equipment, NeoMetrix conducts thorough inspections of aerospace components, detecting even the slightest deviations from specifications. This commitment to excellence instills confidence in every aerospace project, from prototype to production.

Get a Quote- 3D Scanning Services

Precision Redefined: Elevating Aerospace Manufacturing

In the aerospace sector, precision isn’t just a goal—it’s a necessity. NeoMetrix rises to the challenge, redefining precision with its advanced manufacturing capabilities. Through state-of-the-art 3D scanning and 3D printing technologies, NeoMetrix delivers components and parts with impeccable accuracy, meeting the stringent standards of aerospace engineering.

Innovation at Mach Speed: Accelerating Aerospace Development

Innovation fuels progress in aerospace, and NeoMetrix serves as the catalyst for groundbreaking advancements. By harnessing the power of 3D printing, NeoMetrix enables rapid prototyping and production of complex aerospace components. This agility accelerates development timelines, allowing aerospace companies to stay ahead of the curve in an ever-evolving industry.

Get a Quote- 3D Printing Services

“The aerospace industry is one of the top industries we serve with our 3D scanning and printing services.”

“The aerospace industry is one of the top industries we serve with our 3D scanning and printing services.”

“These solutions play a pivotal role in revolutionizing design, manufacturing, and maintenance processes. In aerospace, 3D scanning enables precise replication of complex components, facilitating the creation of lightweight, aerodynamic structures, crucial for optimal performance and fuel efficiency in aircraft. Moreover, it ensures accurate inspection and maintenance of aircraft, enhancing safety and reducing downtime.”

Mandy Howard, NeoMetrix, Account Manager – 3D Printing, 3D Scanning Solutions Sales & Services

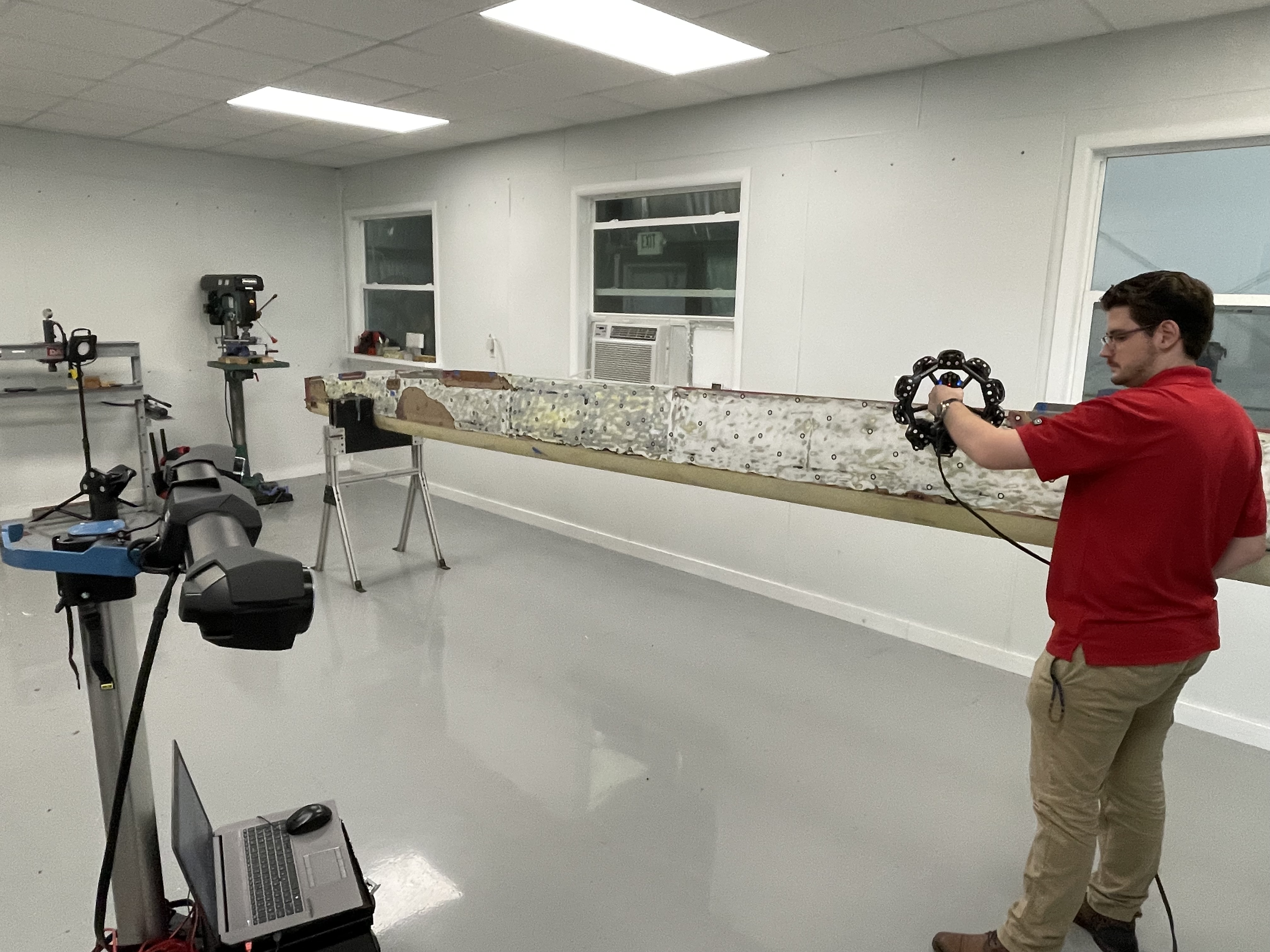

3D Scanning Services

Reverse Engineering Services

Computer-Aided Inspection

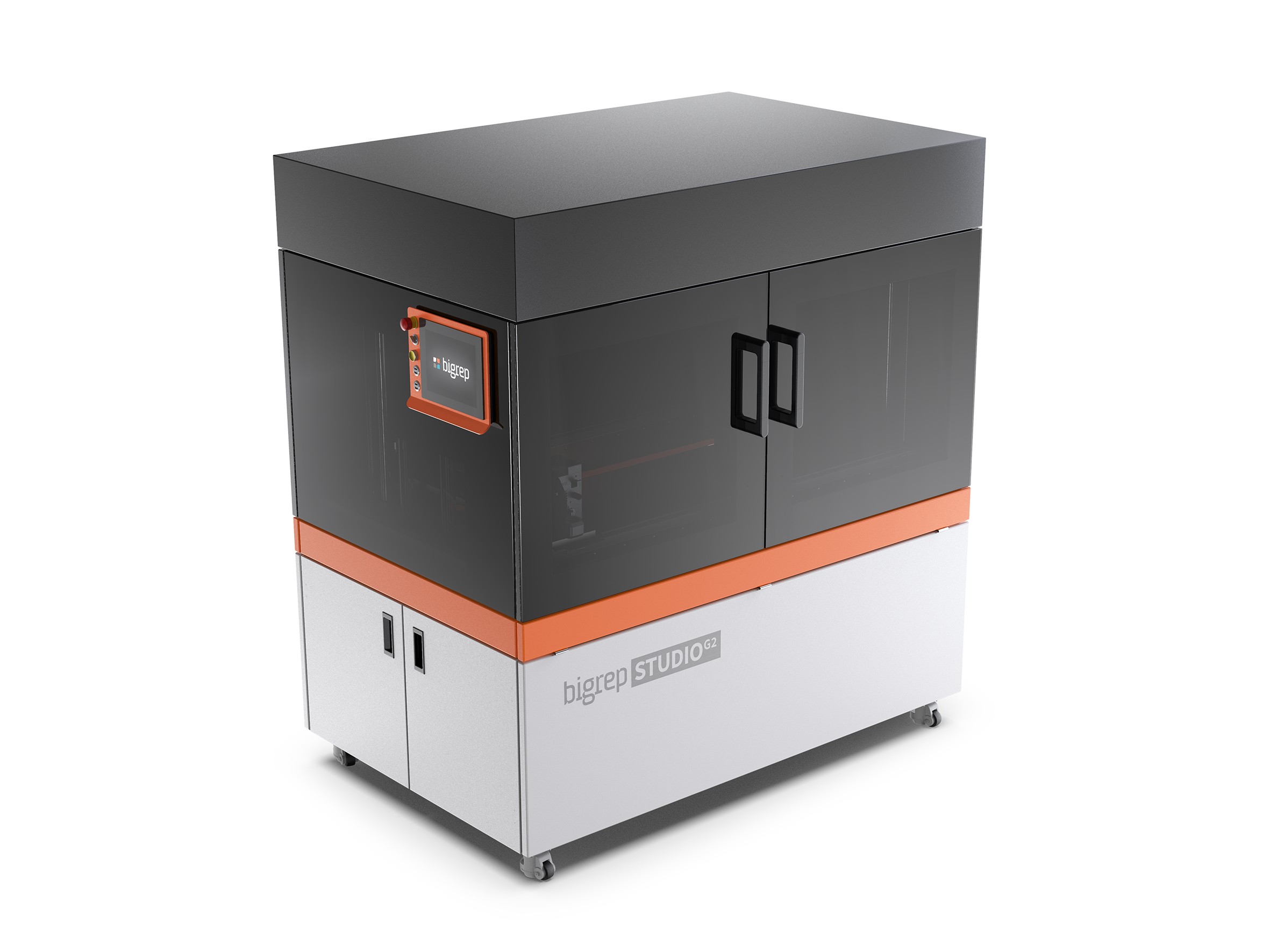

3D Printing Services

Advancing Aerospace Development

3D Scanning, non-destructive testing techniques, digital twin technology, advanced CMMs, and remote sensing and inspection are revolutionizing the way measurements are conducted in the aerospace sector.

For prototyping and low-volume end-use parts, 3D Printing is a key player in the early stages of many development processes.

Here are some of our latest Case Studies that have boosted aerospace businesses:

Reverse Engineering a B747 Support Beam

DER Services contracts NeoMetrix to re-engineer aircraft hardwar

Aircraft Glove Compartment | Complete Reverse Engineering Solution

Using 3D Scanning and 3D Printing in combination to reproduce dated and damaged components.

3D Scanning & Reverse Engineering an Aircraft

Creating a 3D CAD Model of Dassault Falcon F10

Advancing Aerospace Maintenance:

NeoMetrix Technologies Digitizes Helicopter Blades for Advanced Composite Structures

Applications of 3D Scanning in Aircraft Inspection:

Turbine Blades: Turbine blades are critical components of aircraft engines. 3D scanning ensures precise measurement and inspection of these blades for defects, wear, or damage.

Airframe Components: Various structural components of the aircraft, such as fuselage sections, wings, and tail assemblies, undergo 3D scanning for quality control and dimensional accuracy.

Interior Components: Cabin interiors, including seating arrangements, overhead bins, and panels, are scanned to ensure proper fit, finish, and compliance with safety regulations.

Composite Structures: Many modern aircraft incorporate composite materials for their lightweight and durable properties. 3D scanning allows for thorough inspection of composite structures to detect any delamination, voids, or other defects.

Aircraft Maintenance: During routine maintenance and repairs, 3D scanning aids in assessing the condition of parts, identifying areas of concern, and ensuring proper alignment and assembly.

Parts of Aircraft Prototyped Using 3D Printing:

Air Ducts and Vents: 3D printing enables rapid prototyping of air ducts and vents, allowing engineers to optimize airflow and ventilation systems for maximum efficiency and comfort.

Interior Components: From overhead stowage bins to tray tables and seat components, 3D printing facilitates the prototyping of interior fixtures with intricate designs and customized features.

Aircraft Brackets and Mounts: Brackets and mounts used for securing various components within the aircraft, such as avionics equipment or lighting fixtures, can be prototyped using 3D printing for quick iteration and testing.

Tooling and Jigs: Aircraft manufacturing often requires specialized tooling and jigs for assembly and alignment tasks. 3D printing allows for the rapid production of custom tooling to streamline manufacturing processes.

Aerodynamic Components: Wingtips, fairings, and other aerodynamic components benefit from 3D printing during prototyping phases, allowing engineers to optimize designs for reduced drag and improved performance.

Partnering for Success: NeoMetrix and Aerospace Innovation

In the advancing world of aerospace, collaboration is key to success. NeoMetrix stands as a trusted partner for aerospace companies seeking to push the boundaries of innovation. With tailored solutions and unparalleled expertise, NeoMetrix empowers aerospace developers to realize their boldest visions and propel the industry forward.

Discover YOUR SOLUTION NeoMetrix Technologies and unlock the potential of aerospace manufacturing and inspection today.

Need 3D Scanning Solutions?

Inspection, Quality Assurance, Reverse Engineering, 3D Modeling

Need 3D Printing Solutions?

3D print your parts or prototype a produce in engineering-grade materials.