Aircraft Glove Compartment | Complete Reverse Engineering Solution

In this Case Study, see how 3D solutions work together collectively to produce parts for aerospace and many other industries!THE PROBLEM

Nexair Avionics upgrades instrument panels for existing aircraft to incorporate the latest in digital instrumentation. In the process of upgrading, existing parts not related to instrumentation may need to be updated or replaced. In the case of this project and new glove box was required for a Cirrus SR22 aircraft. Unfortunately, this part was no longer available from the manufacturer.

TRADITIONAL METHOD

Traditionally, the original part would be removed, and then painstakingly reverse-engineered by hand using tools such as calipers to take measurements and manually enter them into a CAD program to create a 3D model. Anyone in the aerospace industry understands that aircraft parts in particular are very difficult to measure by hand due to the complex geometry… even on something as “simple” as a glove box. This leads to a high potential for errors in the initial redesign which results in multiple iterations in order to get a final part that fits properly.

NEOMETRIX SOLUTION

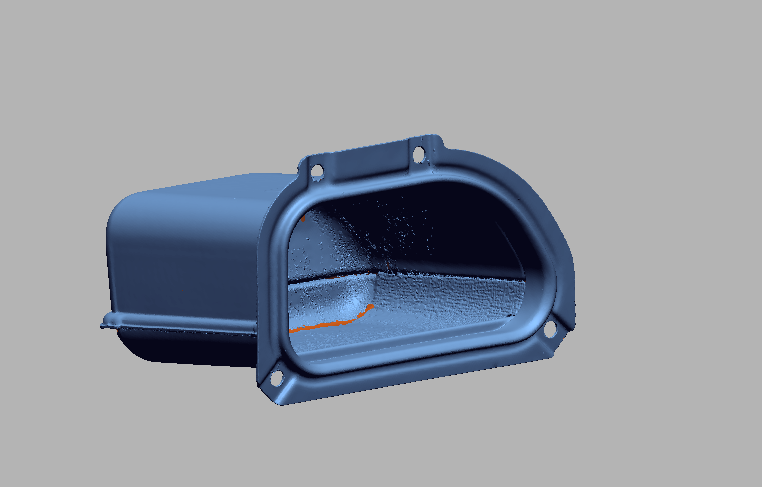

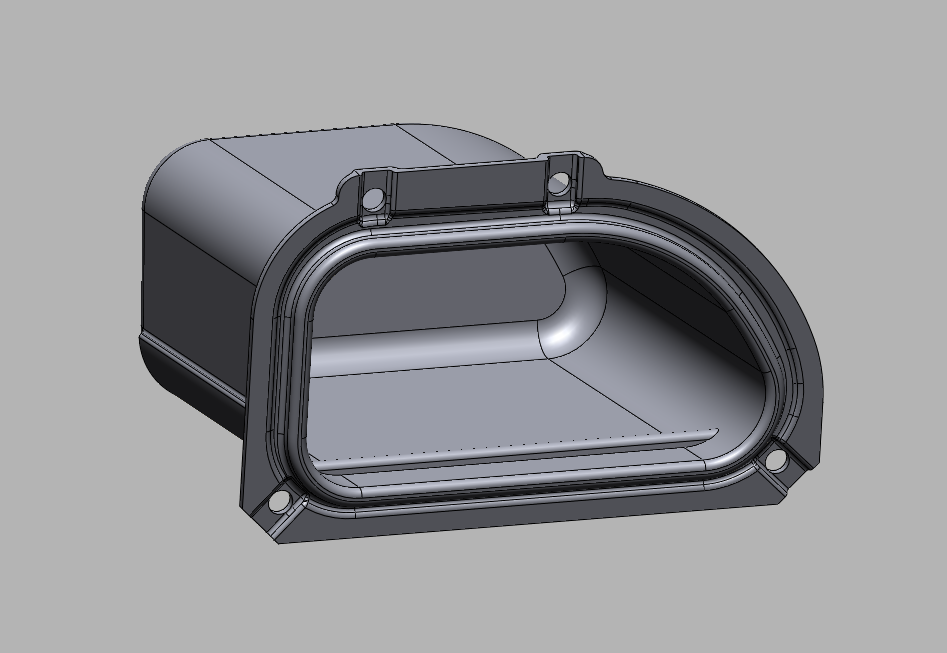

NeoMetrix uses state of the art 3D scanning technology, such as the Creaform HandySCAN Black Elite to rapidly capture the shape of existing parts such as the aircraft glove box. The raw data, which is accurate to .001″ on a part of this size, is automatically converted to an STL file. The STL is then transferred to Geomagic Design X for processing into a highly accurate 3D CAD model. Design X offers tools such as the Accuracy Analyzer, which allows the operator to constantly compare his CAD work back to the original scan ensuring a balance between accuracy and design intent.

NeoMetrix uses state of the art 3D scanning technology, such as the Creaform HandySCAN Black Elite to rapidly capture the shape of existing parts such as the aircraft glove box. The raw data, which is accurate to .001″ on a part of this size, is automatically converted to an STL file. The STL is then transferred to Geomagic Design X for processing into a highly accurate 3D CAD model. Design X offers tools such as the Accuracy Analyzer, which allows the operator to constantly compare his CAD work back to the original scan ensuring a balance between accuracy and design intent.

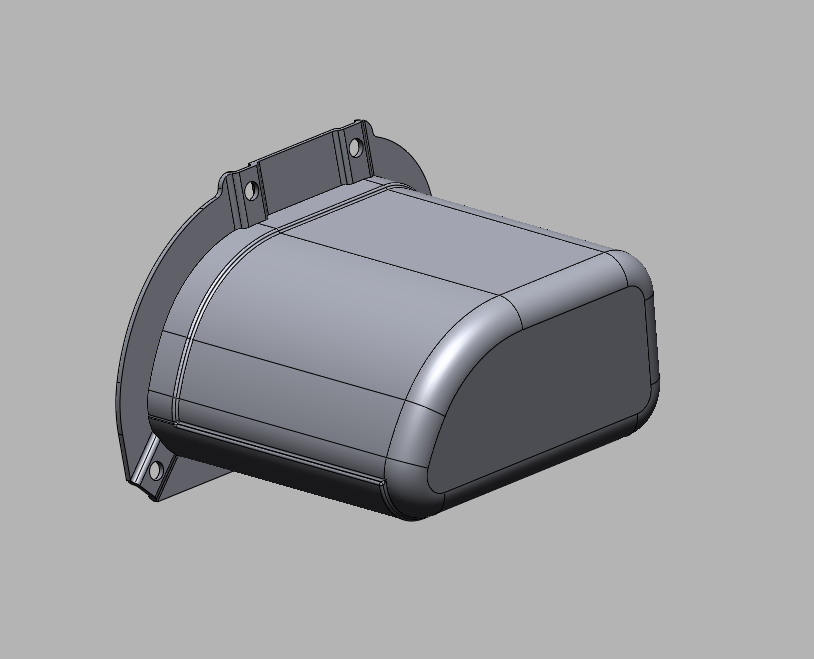

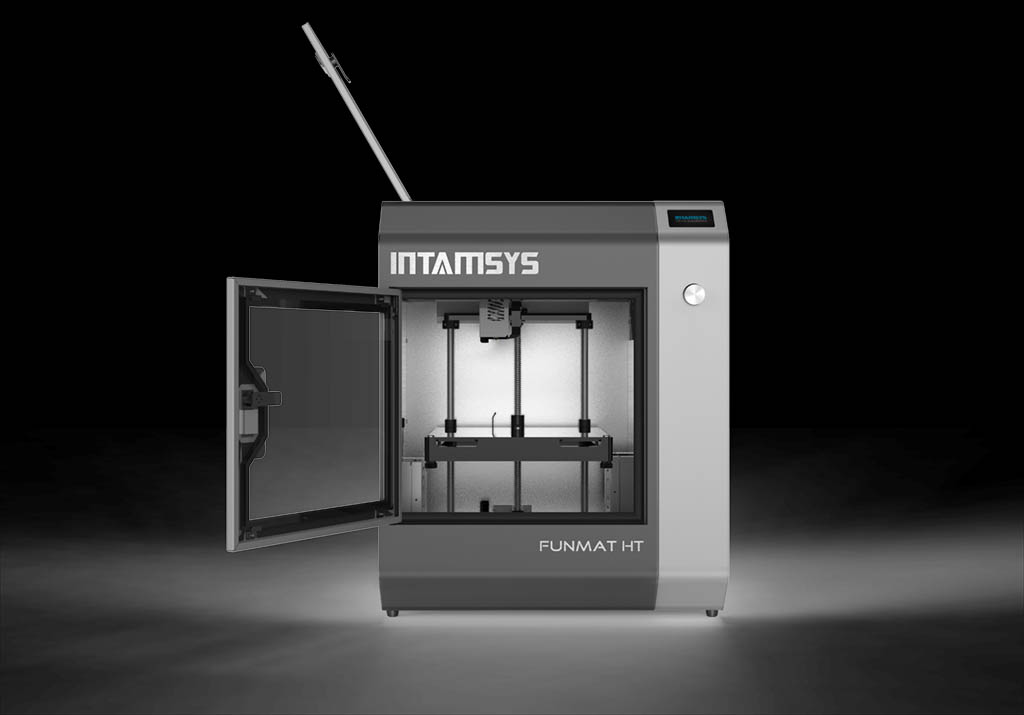

In this case, the final model was re-engineer needed to take advantage of 3D printing. The original part was a multi-piece assembly composed of different vacuum-formed panels which were bonded together to complete the unit. The new redesign is a single component that can be 3D printed in one piece on systems such as the Intamsys FUNMAT HT.

Final 3D Scan Data

Final CAD Model

Final CAD Model

Capture Surface Data for Mounting Area

Reverse Engineering Software

Desktop 3D Printing

NEOMETRIX ADVANTAGE

The use of the HandyScan Black Elite and Geomagic Design X significantly decreases the number of design cycles required to fabricate a new part. In fact the first iteration of the new design fit like a glove (pun intended). Secondly, the use of 3D printing for prototyping and production eliminates the need for expensive tooling. Utilizing this direct digital manufacturing process also enables quick and cost-effective design changes on the product since there are no tooling costs to consider.