From custom parts for machinery to personalized packaging designs, 3D printing is revolutionizing the way food and beverage companies operate.

The landscape of the food and beverage industry is rapidly evolving, with innovative technologies like 3D printing leading the charge in transformation. At NeoMetrix, we understand the importance of staying ahead of the curve, which is why we offer cutting-edge 3D printing and 3D scanning solutions tailored to meet the unique needs of companies in this dynamic sector.

- Custom Parts and Tools for Breweries and Wineries

- Personalized Packaging Designs

- Rapid Prototyping with Thermoforming

- On-Site Spare Parts Production

- Direct Digital-to-Physical Tool Creation

- Print in Engineering-Grade and Food-safe Materials

Revolutionizing Production Processes with 3D Printing

Breweries, wineries, and other related industries that need access to innovative equipment to engineer ideas and produce to life are leveraging this technology to create cost-effective custom parts for their equipment, streamlining production and minimizing downtime. Similarly, chefs are harnessing the power of 3D printers to craft bespoke kitchen utensils that enhance efficiency and cater to their specific requirements.

Moreover, the flexibility of 3D printing enables brands to stand out in a crowded market by offering unique packaging solutions that resonate with consumers. By producing packaging on-demand, companies can reduce storage space and minimize waste, leading to significant cost savings and environmental benefits.

In-house 3D printers can be utilized by a variety of food and beverage-related establishments

Breweries

Breweries can use 3D printers to create custom tap handles, fermenter parts, or even specialty beer glasses with intricate designs.

Food Manufacturing Facilities

Companies involved in food production can employ 3D printers to create custom molds for chocolates, candies, or other confectionery items, as well as to produce prototypes for new packaging designs.

Catering Companies

Catering businesses can utilize 3D printers to produce unique tableware, decorations, or edible centerpieces for events and special occasions.

Food Packaging Companies

Manufacturers of food packaging materials can use 3D printing to prototype and produce custom packaging solutions tailored to the specific requirements of their clients.

Restaurant Chains

Larger restaurant chains may have centralized production facilities where 3D printers can be used to create standardized components for food presentation or branding purposes.

Specialty Food Stores

Specialty food stores can leverage 3D printing to create custom molds for artisanal chocolates, cheeses, or other delicacies, allowing for unique and visually appealing product offerings.

Research and Development Laboratories

R&D labs in the food and beverage industry can utilize 3D printers for prototyping new food products, experimenting with novel ingredients, or developing specialized equipment for food processing.

Enhancing Packaging Prototyping with 3D Printing and Thermoforming

NeoMetrix’s 3D printing solutions, combined with thermoforming technology, empower food and beverage companies to expedite the prototyping process for packaging designs. This rapid prototyping capability allows for the efficient testing and refinement of packaging concepts, resulting in superior product features and enhanced consumer experiences.

By experimenting with various shapes, sizes, and materials, businesses can optimize product protection and aesthetic appeal while reducing time-to-market. Additionally, on-demand production capabilities minimize the need for large inventories, contributing to sustainability efforts by reducing waste.

Streamlining Development and Maintenance with On-Site 3D Printing

In the fast-paced environment of food and beverage production, downtime due to machinery breakdowns can be costly. With NeoMetrix’s on-site 3D printing solutions, companies can produce spare parts for production machinery quickly and efficiently, minimizing downtime and maximizing productivity.

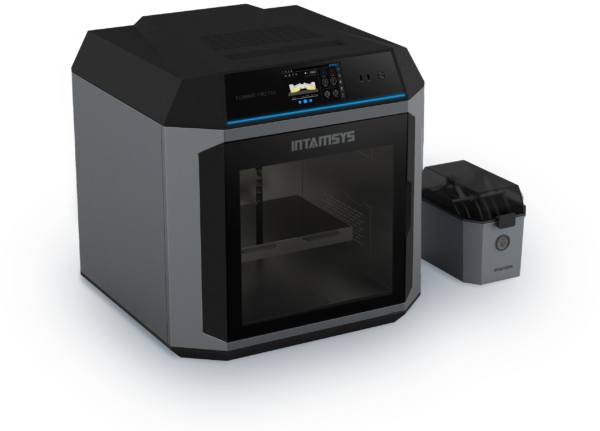

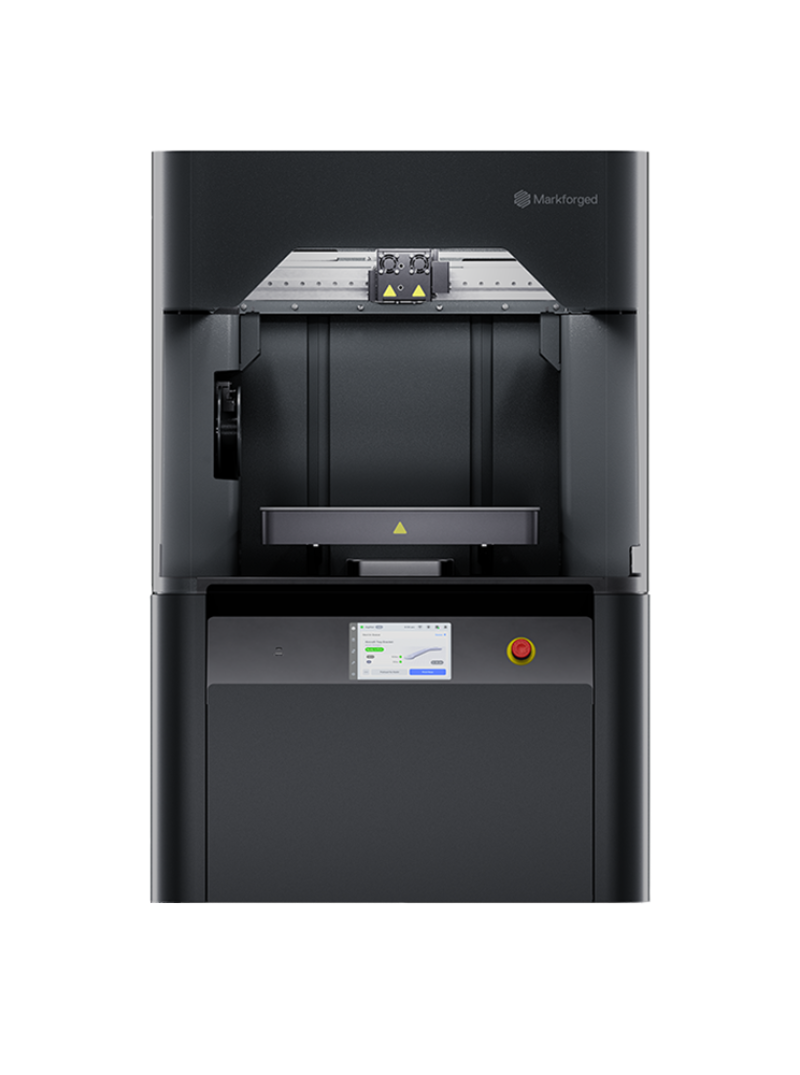

Our 3D printers enable businesses to create custom parts tailored to their unique equipment requirements, eliminating the need for costly inventory and reducing lead times associated with traditional manufacturing methods. From maintenance tools to safety equipment, our on-site 3D printing capabilities empower companies to keep their operations running smoothly without relying on external suppliers.

Combining 3D Printing and 3D Scanning for Engineered Excellence

The integration of 3D printing and 3D scanning technologies presents promising avenues for further development within the food and beverage industry. By combining 3D scanning capabilities to capture intricate details of food items and surfaces with 3D printing’s capacity to precisely replicate these designs, establishments can enhance their product offerings and operational efficiency. For instance, breweries can utilize 3D scanning to digitize unique bottle designs or craft beer glasses, which can then be replicated or customized using 3D printing technology.

Similarly, food manufacturing facilities can employ 3D scanning to create precise molds for chocolates or confectionery items, streamlining production processes and enabling the production of intricate designs at scale. Furthermore, combining these technologies enables rapid prototyping of new product concepts, customized packaging solutions, and even personalized culinary creations, empowering businesses to innovate and differentiate themselves in an increasingly competitive market.

Unlock Your Company’s Potential with NeoMetrix

At NeoMetrix, we’re committed to helping food and beverage companies unlock their full potential through innovative 3D printing and scanning solutions. Whether you’re looking to optimize production processes, enhance packaging design, or streamline maintenance operations, our team of experts is here to support you every step of the way.

Contact us today to schedule a free consultation and discover how NeoMetrix can help your company thrive in the rapidly evolving food and beverage industry.

Explore 3D Printers