In the high-speed, high-stakes world of jet engine drag racing, every fraction of a second can make the difference between victory and defeat. For drivers like Josette Roach, one of only five female jet dragster drivers in the entire world, the quality of every component in their cars is a matter of life and death.

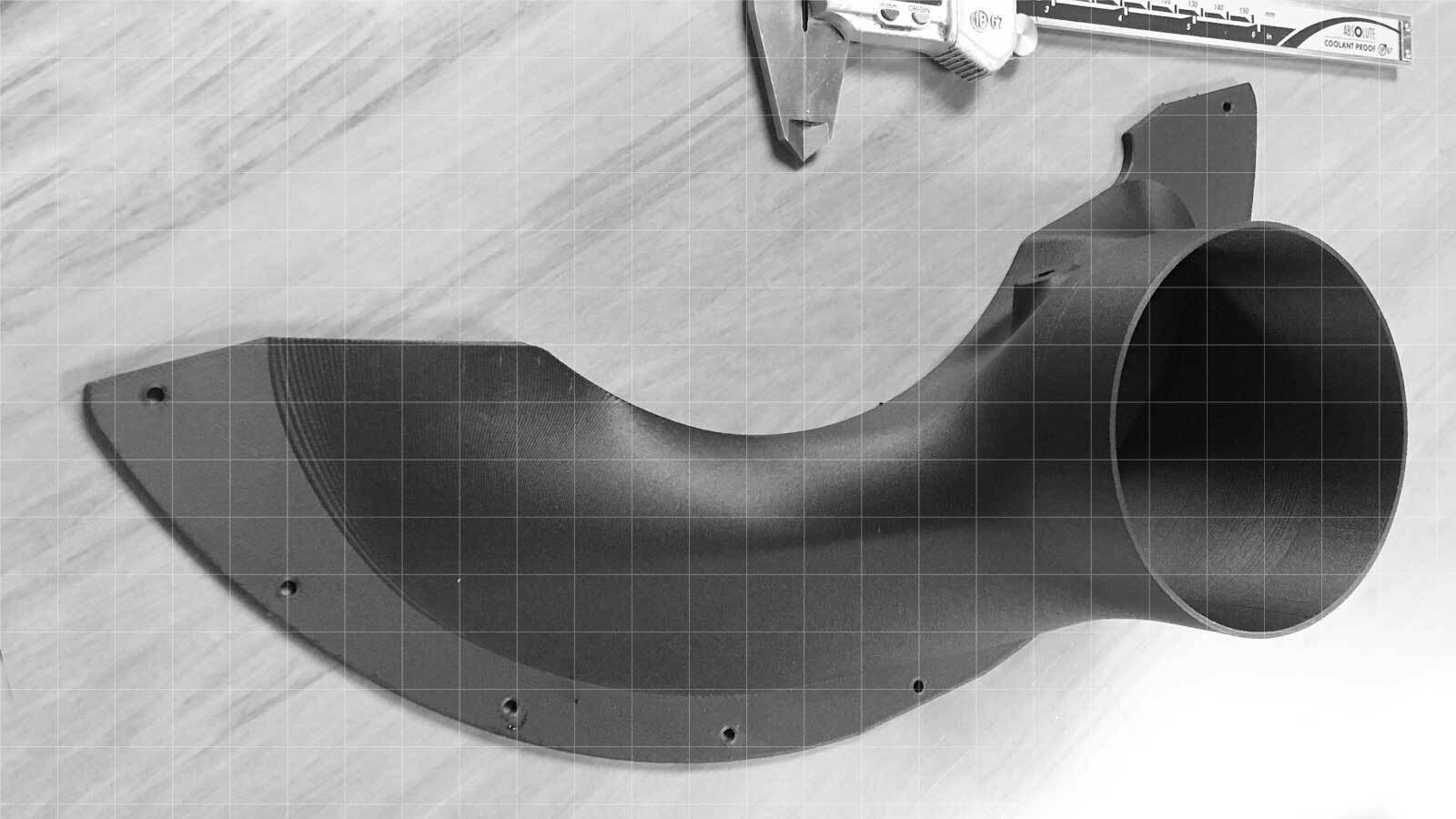

That’s why Josette and her team at Larsen Motorsports saw the need to create a custom steering wheel for her jet car that would fit her hands perfectly. But with traditional manufacturing methods, creating such a precise part could take weeks and be prohibitively expensive. That’s where 3D printing comes in.

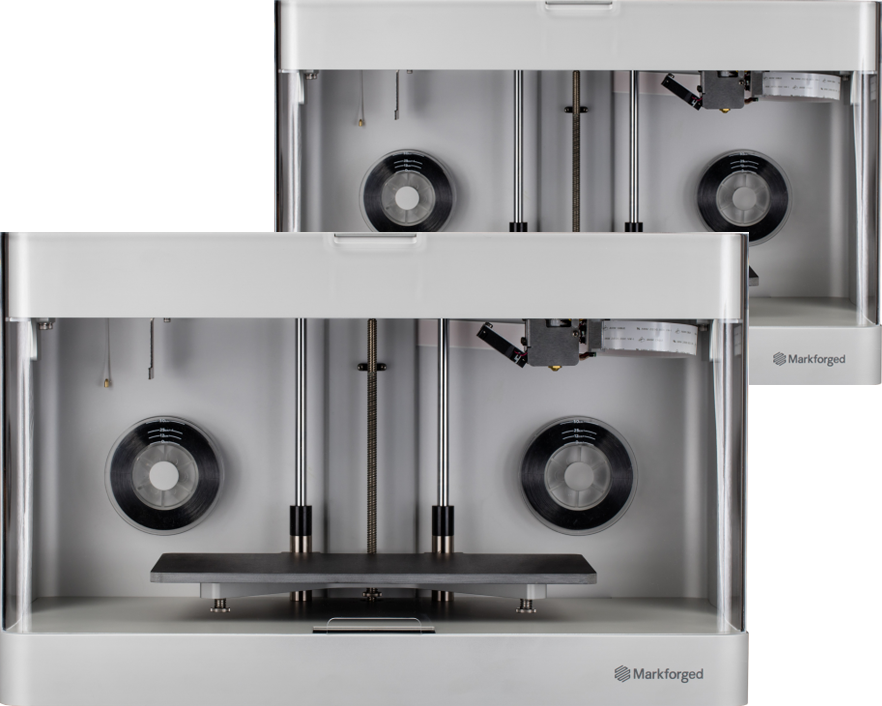

By having access to Markforged 3D Printers in their own in-house facility, the Larsen Motorsports team was able to build Josette’s custom steering wheel with top-end accuracy. No longer did they have to wait over a week for parts to arrive. Instead, they were able to print parts within thousandths of an inch, ensuring the perfect fit for Josette’s hands.

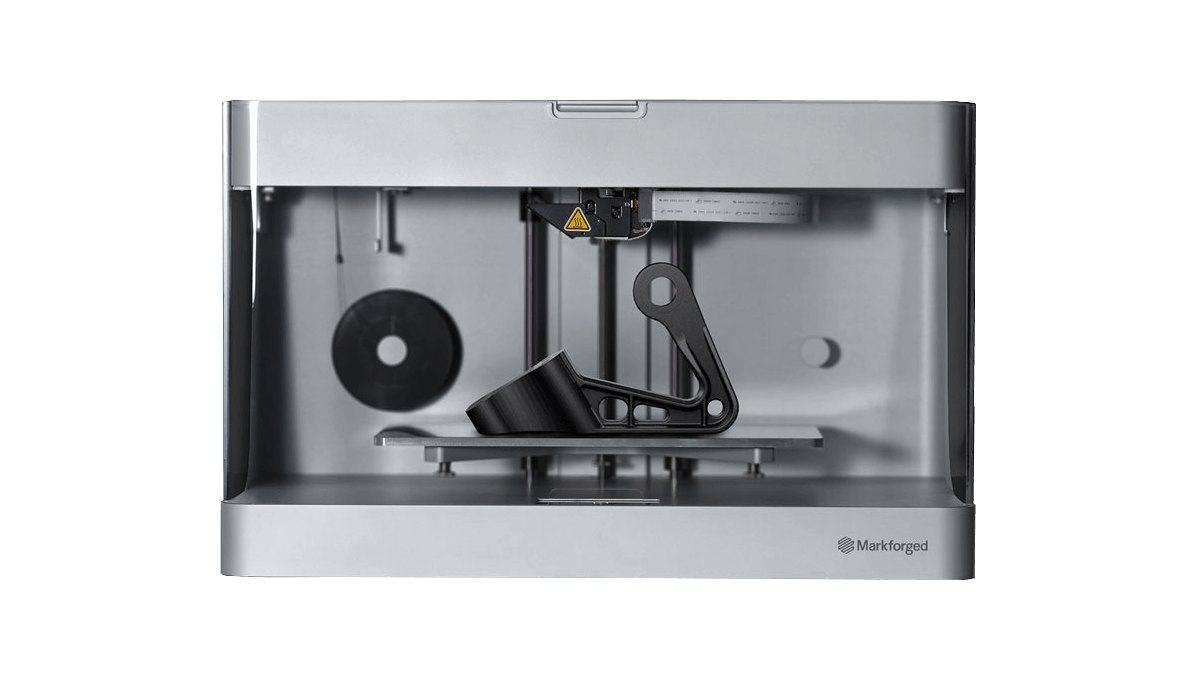

But the key takeaway from this story is not just the speed and precision of 3D printing. It’s the fact that by 3D printing this custom steering wheel, the Larsen Motorsports team did not sacrifice any strength. The part that came off the Markforged printer has carbon fiber reinforcements and is on par with the strength of aluminum.

3D Print Strong, Lightweight, and Reinforced

Markforged Mark Two

Markforged X7

For industries like jet engine drag racing, where every component must be able to withstand extreme forces and temperatures, this is a game-changer. With 3D printing, engineers can create parts that are not only highly precise, but also incredibly strong and durable. And with the ability to print parts in-house, the entire manufacturing process becomes faster, more efficient, and more cost-effective.

For Josette Roach and her team at Larsen Motorsports, 3D printing has enabled them to push the limits of what’s possible in their sport. But the applications of this technology go far beyond drag racing. From aerospace to medicine, 3D printing is revolutionizing the way we think about manufacturing and design. And with each new innovation, the possibilities only continue to grow.

Simulation – Learn more

With Simulation, Larsen Motorsports can take a supply chain shortcut without cutting any corners in quality. The steering wheel can be easily customized and quickly fabricated with full confidence it will continue to perform.