Pushing the Boundaries of Additive Manufacturing technology with the Peel 3 3D Scanner, BigRep Studio G2, and ProHT Material

In this article, we will explore ways in which the combination of 3D Scanning and 3D Printing technologies can improve many creative and design cycles. By utilizing these additive manufacturing technologies, tasks that typically require hours or even days can now be accomplished in a matter of minutes with greater precision and reliability.

3D Scanning Original Deer Skull

By utilizing the Peel 3 3D scanner, we managed to obtain precise measurements of the surface of the deer skull, transforming it into a digital mesh. The Peel 3 scanner performs exceptionally well in capturing the color and texture of surfaces, resulting in an accurate representation of the original object in the scanned mesh. Generating a digital replica of the deer skull took mere minutes. Our next objective was to exploit the capabilities of 3D printing technology by creating a life-size replica of the skull.

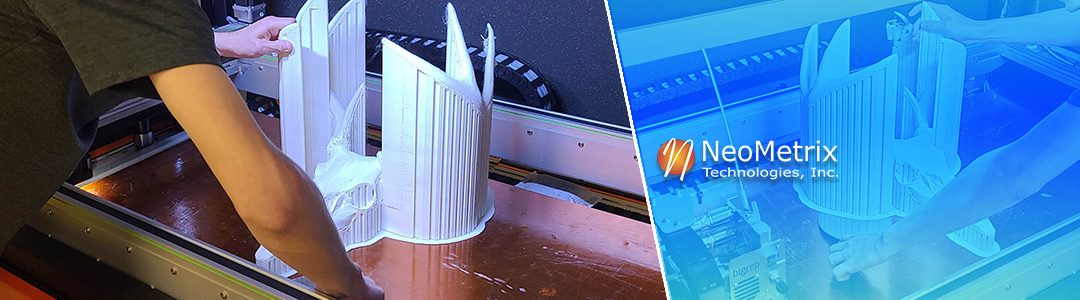

3D Printing- From Digital Scan to Physical Object

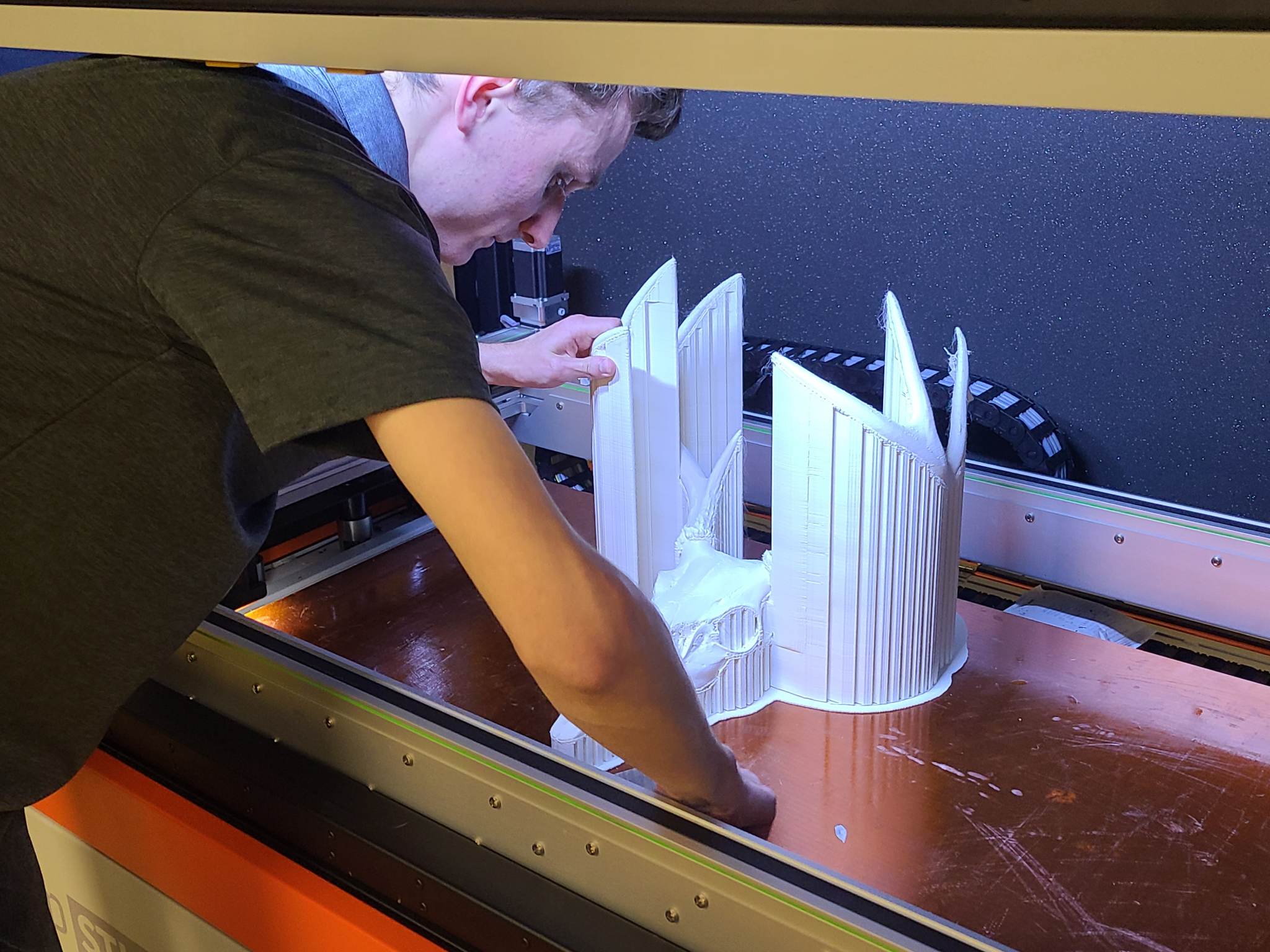

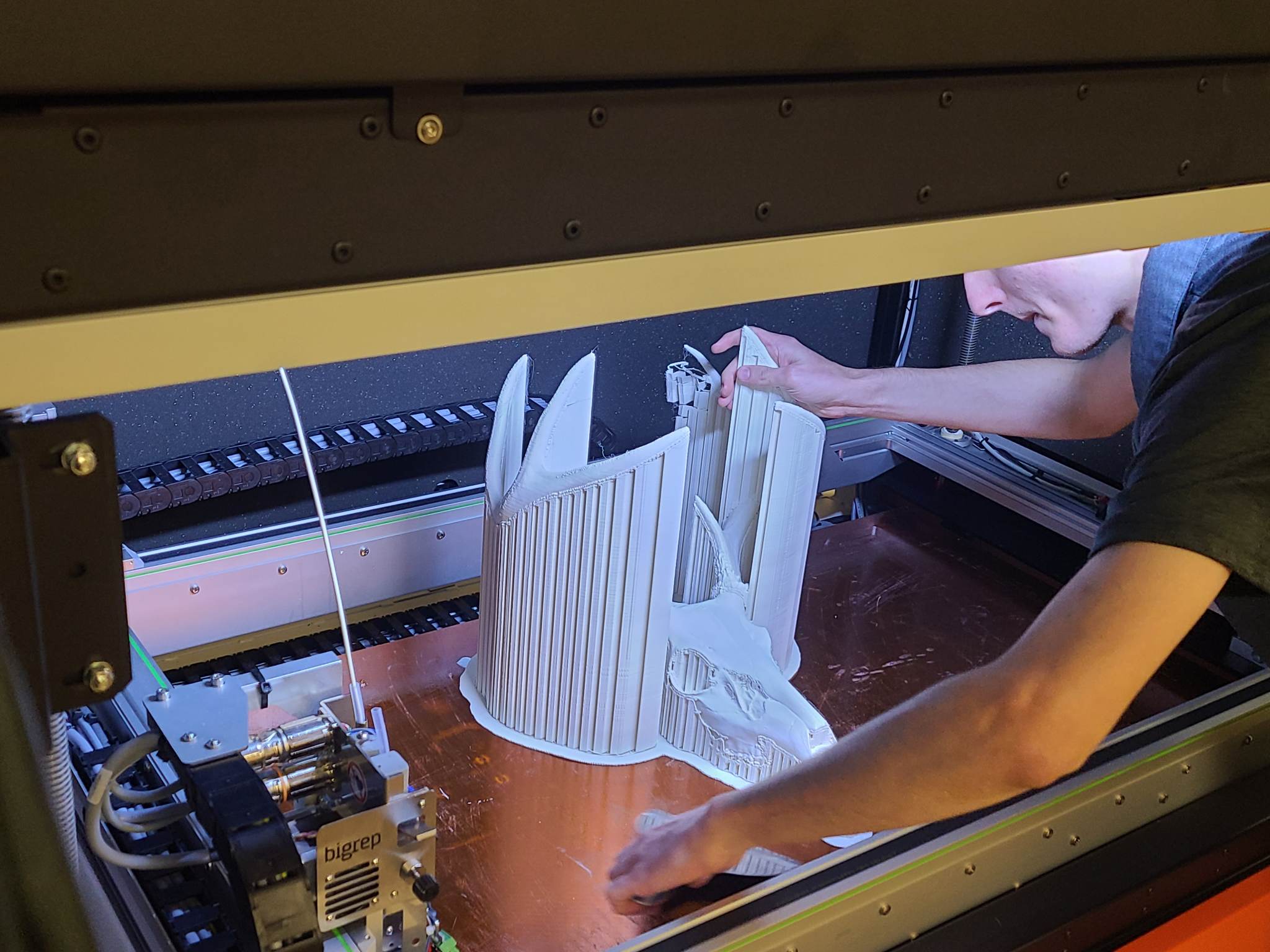

At NeoMetrix Technologies, we are always looking for ways to push the boundaries of 3D printing technology. Recently, we were able to accomplish a significant feat by 3D printing a large deer skull that measures 482mm in length and 406mm in height using the BigRep Studio G2.

To achieve this, we used Pro HT material, which has several advantages over other materials. One of the most significant advantages is its ease of support removal. This material is designed to be easily removed from support structures, which makes the post-processing work much faster and more efficient. The full print time was 3 days (72 hours).

Additionally, Pro HT is a high-temperature thermoplastic that has excellent strength and durability. This material is perfect for creating large, functional parts that need to withstand high stresses and heavy loads. The high-temperature resistance also makes it suitable for use in industrial applications that require exposure to high temperatures and harsh environments.

The Most Competitive Features- Studio G2

The BigRep Studio G2 is a top-of-the-line 3D printer that has a range of impressive features and capabilities. It has a build volume of 1005mm x 1005mm x 1005mm, which is one of the largest build volumes available in the market. This printer is also equipped with a dual extruder system that allows for the printing of complex geometries and the use of multiple materials.

One of the most impressive features of the BigRep Studio G2 is its precision and accuracy. This printer is capable of producing parts with layer resolutions as low as 0.1mm, which makes it perfect for producing highly detailed and intricate parts.

Perfect Solution for Big Ideas

In summary, our NeoMetrix team was able to push the boundaries of 3D printing by using the BigRep Studio G2 to create a large deer skull using Pro HT material. The ease of support removal and high-temperature resistance of this material make it ideal for producing functional parts that can withstand heavy loads and harsh environments. The BigRep Studio G2’s impressive build volume, dual extruder system, and precision and accuracy make it an excellent choice for industrial and commercial applications.