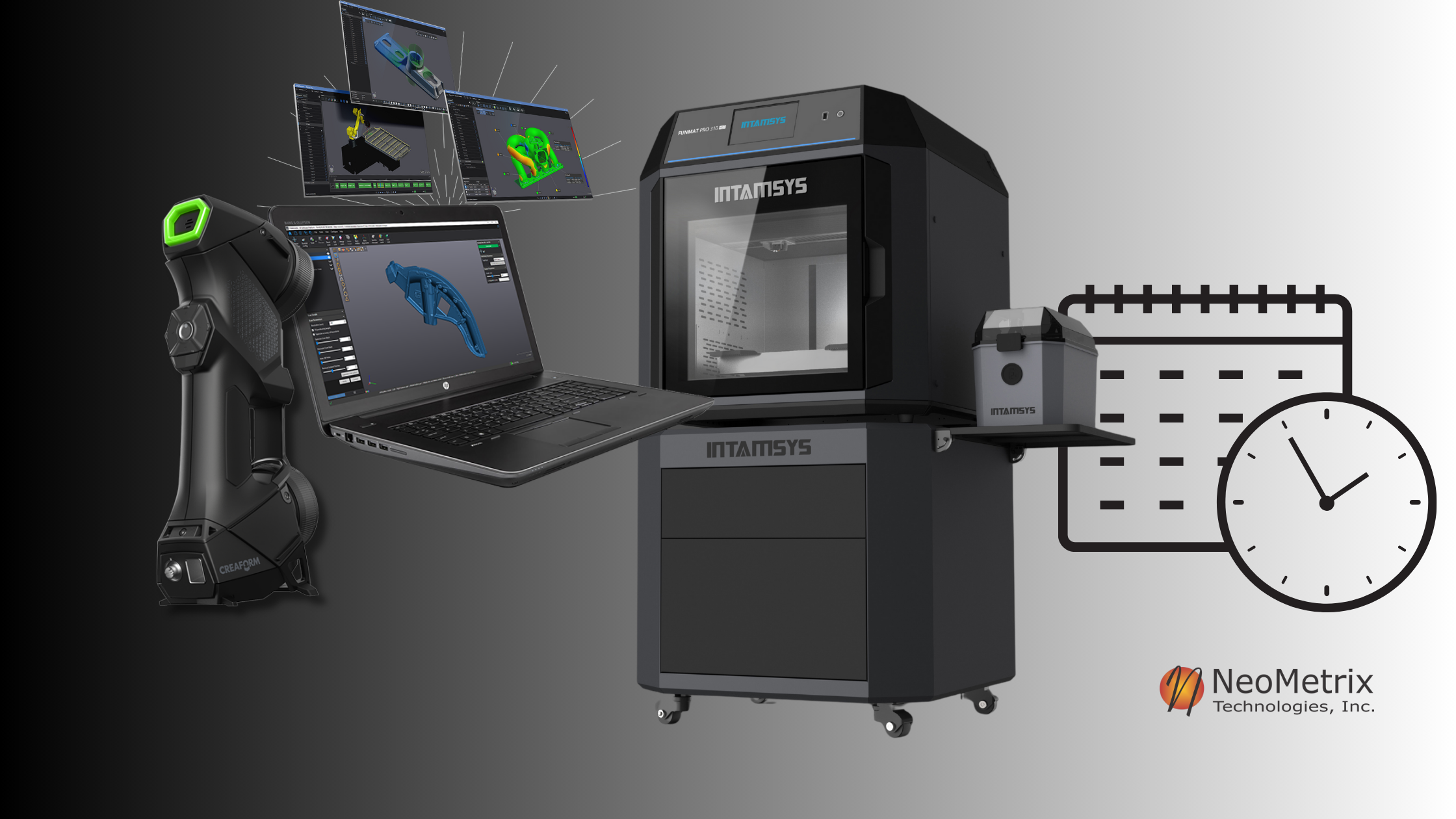

3D Scanning technology has empowered innovators, fabricators, and custom builders with elite solutions —transforming guesswork into guaranteed precision.

That’s where 3D scanning comes in—and why NeoMetrix Technologies has played a pivotal role in enabling manufacturers, shops, and individual builders to confidently step into the future of automotive innovation.

For over 20 years, NeoMetrix has supplied elite 3D scanning and reverse engineering solutions to the automotive sector, empowering companies to overcome traditional fabrication challenges, accelerate timelines, and achieve unmatched fitment accuracy.

Why 3D Scanning Is the Game-Changer for Automotive Innovation

Whether you’re designing a one-off custom body or retrofitting a commercial fleet, traditional manual measurement and templating are outdated and error-prone. High-precision 3D scanning eliminates the uncertainty.

Key Benefits for Automotive Applications:

-

Eliminate fitment issues – Capture complex geometries with metrology-grade accuracy

-

Accelerate production cycles – Go from scan to CAD in hours instead of days or weeks

-

Reduce material waste – No more rework or physical trial-and-error

-

Unlock digital-first workflows – Streamline design, simulation, and prototyping

From individuals building passion projects to enterprise-level manufacturers, NeoMetrix has been the trusted partner for reliable, fast, and intuitive 3D scanning technology.

Why HandySCAN 3D|MAX Stands Out

With this combination, engineers and fabricators can go from raw scan data to ready-for-production 3D models without bottlenecks. At the heart of these success stories is the HandySCAN 3D|MAX Series, the gold standard in portable, high-accuracy scanning for large and complex automotive parts.

Key Specs & Advantages:

-

Metrology-grade accuracy: Up to 0.015 mm and ISO 17025 accredited

-

Large part scanning: Optimized for full vehicle bodies, roll cages, chassis, and more

-

Portability: Lightweight, handheld design usable in real-world conditions—even outdoors

-

Speed: Captures millions of points per second for fast, high-res scans

-

Creaform OS + Scan-to-CAD module: Seamless reverse engineering workflows with real-time deviation analysis and CAD extraction tools

-

Technical Advantage: Scale Bars and Flex Volume features allow you to capture parts of LARGE SIZE.

Discuss Your Solutions and Business Applications with an Engineer

PROVEN IN THE FIELD – The HandySCAN 3D|MAX Series makes it easy to 3D scan large vehicle parts in minutes.

Starr Creations team members use 3D scanning to capture 3D measurements of monster trucks.

Starr Creations’ Leap Forward with HandySCAN 3D|MAX

Starr Creations, a custom automotive design powerhouse based in Tampa, turned to 3D scanning to solve a critical challenge: designing fiberglass monster truck bodies without having the physical chassis on-site. With the Creaform HandySCAN 3D|MAX Series, provided and supported by NeoMetrix, the team was able to remotely scan chassis, create precise digital models, and build bodies that fit perfectly—without rework.

This tech also helped revolutionize a custom build for Cleetus McFarland’s drag racer Leroy, where the scanner’s high-resolution data enabled an aerodynamically optimized body redesign. Results from wind tunnel testing exceeded digital predictions—testament to the accuracy of the scan data and the performance of the Creaform platform.

Source: https://www.creaform3d.com/en/resources/blog/3d-scanning-mastery-on-the-race-track

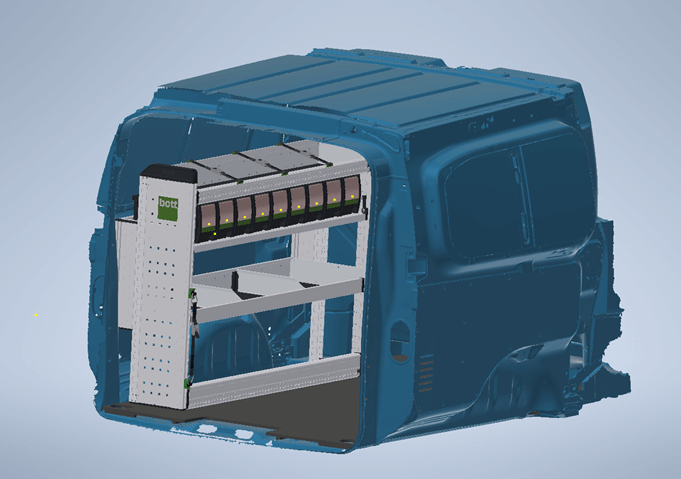

The Bott Group: From Point Clouds to Production-Ready CAD in Record Time

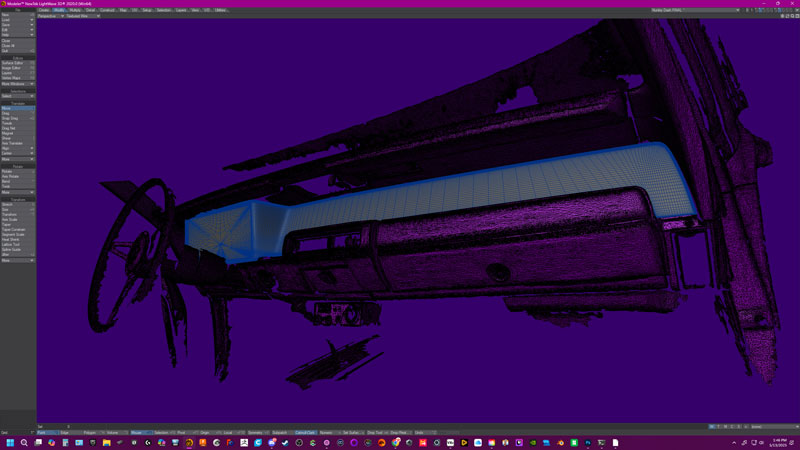

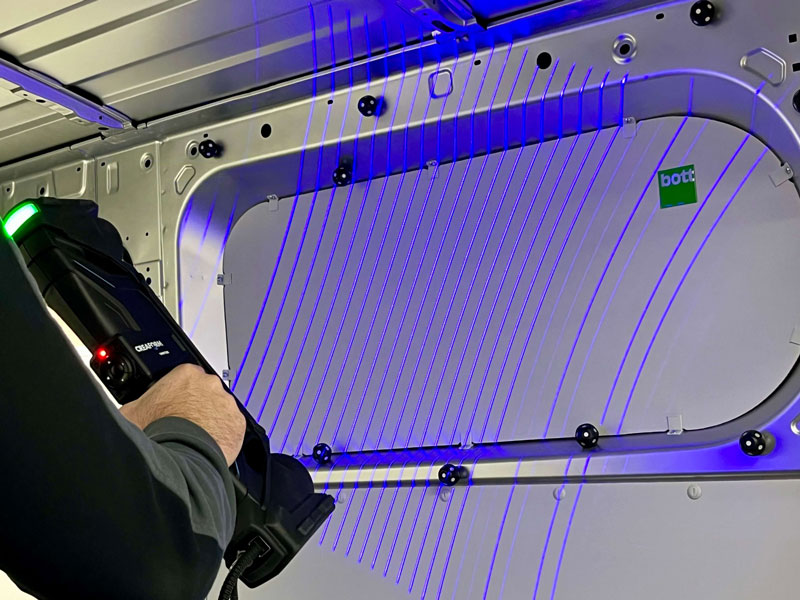

Over in Europe, the bott Group—known for outfitting fleets of service vehicles with custom storage and workspace solutions—ditched legacy point cloud methods in favor of a faster, cleaner solution. With the HandySCAN 3D|MAX and Creaform’s Scan-to-CAD module (part of the Creaform Metrology Suite™), bott engineers reduced scan-to-CAD lead times by three full days per vehicle model.

What once took painstaking manual labor was transformed into an intuitive, repeatable digital workflow—empowering them to take on more vehicle models, faster, and with improved precision.

Source: https://www.creaform3d.com/en/resources/blog/how-bott-cuts-days-from-vehicle-fit-outs-with-3d-scanning

NeoMetrix: Your Trusted Source for Performance-Driven Scanning

NeoMetrix Technologies isn’t just a reseller—we’re a long-standing solutions partner for the automotive industry. From first-time users to seasoned CAD engineers, we provide:

-

Expert support & training for integrating 3D scanning into your workflow

-

Custom consultation to identify the right tools for your application

-

Reverse engineering services for those looking to outsource their needs

-

Pre-owned equipment for cost-effective entry into professional 3D scanning

From the Garage to the Grid: Scale Your Ambitions with Confidence

Whether you’re developing custom performance parts, retrofitting a vehicle for commercial use, or optimizing an aerodynamic body—NeoMetrix Technologies delivers the tools, expertise, and support to make it happen.

“3D Scanning is a real game changer for the aftermarket automotive industry. The ability to rapidly capture the complex geometry of existing cars enables designers to develop new parts that fit correctly on the first pass, eliminating time delays and costly rework.”

-Dan Perreault, President & Lead Engineer of NeoMetrix

MORE AUTOMOTIVE APPLICATIONS

3D Scanning and Rapid Surfacing for Aftermarket Product Development

3D Scanning Enhances Production Rate for Aftermarket & OEM

Classic Cars – 3D Scanning and Production of New or Outdated Parts

Ask us about 3D scanning services and equipment!