Are you facing challenges in accurately measuring corrosion or damage on complex geometries? The reliability of conventional techniques like pit gauges and ultrasonic pen probes can be compromised, leading to biased results and dependency on technician skills. The HandySCAN 3D Scanner is available through experienced providers like our team at NeoMetrix Technologies, offering unparalleled precision and efficiency in corrosion assessment.

In modern manufacturing and maintenance, the precision and efficiency of quality control and corrosion assessment are paramount. 3D scanning technology, a revolutionary tool in this domain, is reshaping how industries approach these critical tasks.

By offering unparalleled accuracy, detailed data acquisition, and significant time savings, 3D scanning stands as a game-changer for businesses looking to optimize their processes. In this blog, we explore the transformative impact of 3D scanning, specifically focusing on its advantages in quality control and corrosion assessment, and how tools like the HandySCAN 3D Scanner from NeoMetrix Technologies are leading this innovative front.

Challenges Addressed by HandySCAN 3D:

- User-Independence: The 3D scanning system ensures that measurements are independent of technician skills, providing consistent results regardless of experience levels. NeoMetrix Technologies offers an easy-to-use solution for reliable data acquisition and analysis.

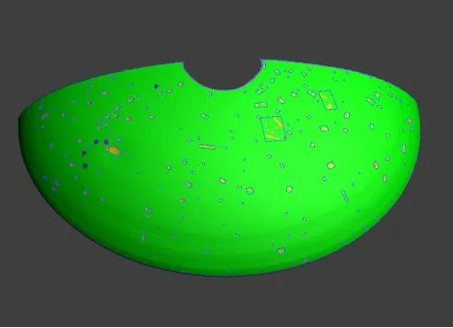

- Accuracy and Full Coverage: Equipped with the Surface Damage Inspection Module, the Creaform Go!SCAN 3D captures the entire surface of corroded areas without omissions. The software utilizes a mathematical algorithm to reconstruct a reference surface, enabling accurate and repeatable thickness loss assessment.

- Ease of Use: The plug-and-play devices, user-friendly interfaces, and preconfigured parameters make capturing the deepest points of corroded, complex areas quick and reliable. NeoMetrix Technologies integrates the Surface Damage Module into a minimal-step workflow, enhancing the efficiency of asset owners and integrity engineers.

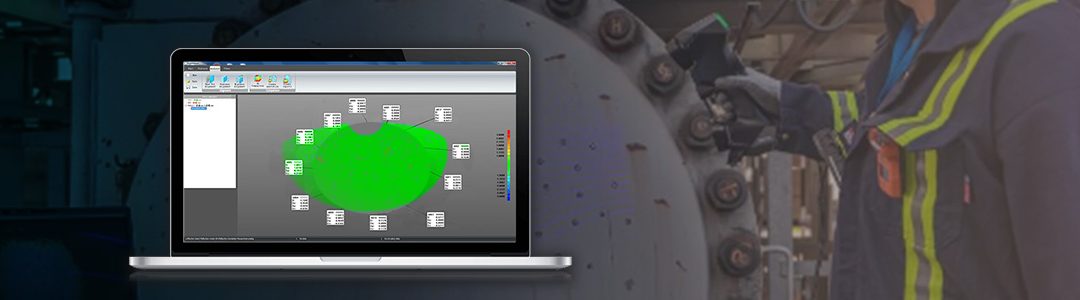

Localized corroded area on a pressure vessel head inspected with Creaform’s VXintegrity and 3D scanning technology

Benefits of Choosing HandySCAN 3D Scanner from NeoMetrix Technologies:

- Precision in Assessment: The HandySCAN 3D Scanner, in tandem with VXintegrity’s Surface Damage Inspection Module, delivers precise measurements of thickness loss on curved and intricate geometries. This precision translates into substantial time and cost savings for plant owners making maintenance decisions.

- Enhanced Communication: Digital measurement and documentation of corroded surfaces enable the generation of comprehensive reports with thickness-mapping Excel grids. These reports, automatically generated by VXintegrity, facilitate communication with experts, providing reliable information even in their absence during inspections.

- Confidence in Results: Unlike traditional methods, the 3D scanning approach with HandySCAN eliminates reliance on technician skills, providing repeatable and accurate results. Plant owners gain confidence in inspection reports for informed assessment and repair decisions.

- Optimized Maintenance Costs: HandySCAN 3D Scanner assists in identifying structures that require priority repairs, allowing infrastructure owners to optimize maintenance costs. Savings in time and money can be directed towards critical structures needing more attention, thereby enhancing overall maintenance efficiency.

Capturing and Analyzing Scan Data is EASY!

Half of a pressure vessel head with localized corrosion on its surface analyzed with the enhanced virtual pit gauge for complex geometries

The HandySCAN Black Elite is part of the new generation of 3D scanners from Creaform.The HandySCAN Black Elite offers increased accuracy and resolution. It is the most versatile 3D scanner on the market for inspection and demanding reverse engineering. Some of the things the HandySCAN Black Elite features:

- Accuracy of 0.025 mm (0.0009 in)

- Mesh Resolution of 0.1 mm (0.0039 in)

- Light Source of 11 blue laser crosses plus 1 extra line

- Scanning area of 310 x 350 mm (12.2 x 13.8 in)

- Has a small weight of 0.94 kg (2.1 lb)

- Measurement rate of 1,300,000 Measurements/s

Elevate your corrosion assessment process with the HandySCAN 3D Scanner from NeoMetrix Technologies – your trusted partner for cutting-edge, reliable, and efficient 3D scanning solutions in industrial applications. Transform the way you approach corrosion inspection and maintenance decisions with the power of HandySCAN 3D.

More 3D Scanners

GoSCAN Spark™

The Go!SCAN Spark product line offers our easiest portable 3D scanning experience, providing exceptionally fast yet reliable measurements. This next generation of scanners has also added full 3D color.

The Go!SCAN Spark features:

- High level of details

- Accuracy of 0.050 mm (0.002 in)

- Color acquisition

- No set-up required

- Worldwide support

- Resolution of 0.1 mm (0.0039 in)

- 1,500,000 measurements/s

- Part size range of 0.1-4 m (0.3-13 ft)

MetraSCAN Black

Highly versatile, the MetraSCAN 3D can be used to scan various part sizes and surface finishes in real time—all with the same device. With its extendable measurement volume, parts of any shape, complexity, and geometry can be measured easily without loss in accuracy or conventional leapfrog. When combined with the HandyPROBE, the measurement system acquires even more versatility: probing for geometrical entities and 3D scanning for complete surface inspection. The MetraSCAN Black features:- Accuracy – 0.025 mm (0.0009 in)

- Volumetric accuracy – 0.064 mm (0.0025 in)

- Reliable acceptance test

- Based on VDI/VDE 2634 part 3 standard

- ISO 17025 accredited laboratory

- Shop floor accuracy with dynamic referencing

- Measurement accuracy insensitive to environmental instabilities

- High resolution

- Masters complex and highly detailed parts