3D Scanners give businesses a competitive edge in precise part measurements, streamlined production workflows, and adaptability to intricate design specifications.

As demand for complex and lightweight components in industries such as automotive, aerospace, & manufacturing products continues to rise, composite manufacturers must adopt advanced solutions to maintain high-quality standards while optimizing speed and efficiency.

One of the most powerful tools available to meet these demands is 3D scanning technology. Leveraging high-accuracy scanners allows composite manufacturers to simplify their inspection processes, improve quality control, and reduce time to market. At NeoMetrix Technologies, we are proud to partner with Creaform to provide industry-leading 3D scanning solutions to companies seeking a technology edge that translates to a competitive edge in composite manufacturing.

The Challenge: Precision and Speed in a High-Demand Industry

Composite manufacturers are constantly balancing customer requirements with strict production timelines. High-precision parts often involve intricate designs that demand rigorous quality control measures at each production stage. However, as the number of parts produced grows, maintaining the same quality and consistency across large volumes becomes increasingly challenging. Additionally, new contracts or custom projects introduce the need for greater flexibility and adaptability in manufacturing processes.

Traditional measurement tools and inspection methods can be slow and may lack the accuracy required for modern composite manufacturing. This can lead to increased costs, wasted materials, and, ultimately, delays in delivery to the customer.

The Solution: 3D Scanning for Accurate, Repeatable Results

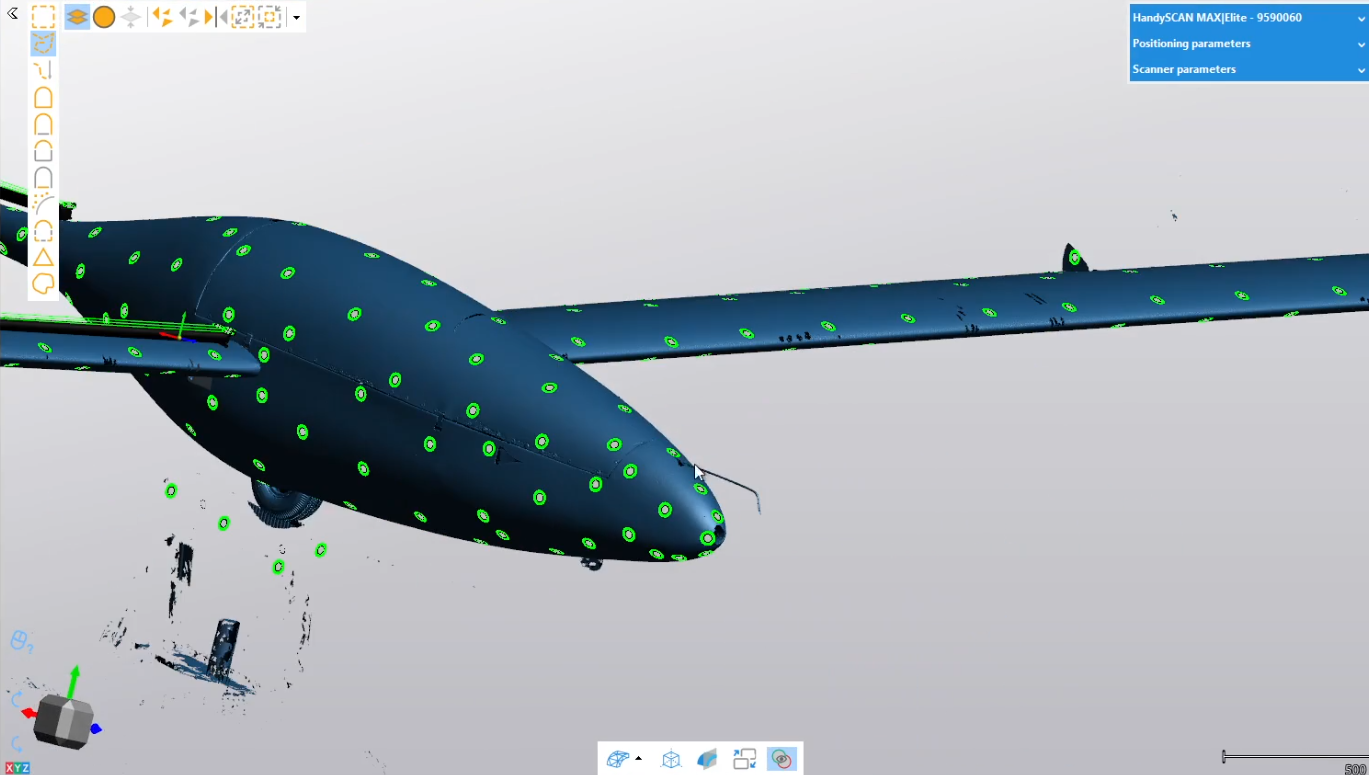

Advanced 3D scanning technology, such as Creaform’s HandySCAN MAX and HandySCAN Black+ Elite Series, offers the precision and repeatability composite manufacturers need to stay competitive. By integrating these tools into inspection workflows, manufacturers can quickly capture exact measurements of complex geometries and identify any potential issues before products reach customers. The result? Faster turnarounds, improved product quality, and enhanced customer satisfaction.

At NeoMetrix Technologies, we help businesses implement these solutions into their processes, often replacing older, less efficient methods with 3D scanners that improve inspection accuracy while being easy to use and compatible with third-party software. This ease of integration is critical for companies with high production volumes, as it minimizes downtime while maximizing operational efficiency.

NeoMetrix 3D Scans 39″ aerospace glider!

Looking for 3D Scanning Equipment?

Real-World Impact: Driving Growth and Customer Satisfaction

The impact of 3D scanning technology on composite manufacturing is clear: it enhances precision, speeds up production, and supports rigorous quality standards. With this technology, manufacturers can respond quickly to changing customer needs and even open up new revenue streams, such as on-site inspection services, further strengthening customer relationships and trust.

At NeoMetrix Technologies, we’ve seen firsthand how investing in the right 3D scanning tools can empower companies to meet—and often exceed—their operational goals. For manufacturers in the composites industry, staying competitive isn’t just about delivering quality parts; it’s about continuously improving processes, meeting higher standards, and adapting to complex designs. With advanced 3D scanning technology, manufacturers gain a powerful advantage, paving the way for long-term success.

We offer flexible financing to help you get the technology as soon as you need. Fill out a Quick Contact Form to get more info.

Ask us about 3D Scanning Equipment & Services