Spain’s Bravo Yacht Design Group (BYD) recently completed its 200th 3D yacht scan. The 73m Lürssen Coral Ocean has just undergone a detailed exterior scan, prior to receiving extensive refit work. It follows hot on the heels of a full interior and exterior scan for the 45m luxury motor yacht Andrea, and means that more than 2,500m of hull length has now been scanned by the firm.

“At that time, we started using it on projects where getting measurements was a real nightmare and not precise, as taking measurements on a boat can be very difficult due to the non-planar shapes of the boat,” explains Tià Simó, co-founder and partner at BYD Group.

“Also, having the peace of mind that measurements are accurate is something that, without 3D laser scanning, is almost impossible, and that’s why most work needed to be done on the yacht. Nowadays, we are fully confident with our ability to build parts away from the boat in a factory with perfect conditions and then assemble them on board.”

From checking that the yacht hulls to mapping of VIP cabins on large motor yachts prior to refit, scanning technology has multiple uses. In 2019, BYD mapped the entire J-Class fleet for rating purposes. The accuracy of BYD’s scanning was also key in designing an extension to the hull of carbon racing yacht Jethou.

Laser scanning can also play an important role in a successful refit projects where the aim is to precisely measure the dimensions of a specific area of the boat ahead of refit work. On the yacht, Cocoa Bean, the measurements were around the funnels and the forward front face of the superstructure for a new sundeck Jacuzzi, while the transom scan for Nostalgia was in preparation for extending the yacht.

“The main benefit of 3D laser scanning ahead of a refit is having accurate data during the redesign phase, which will mean that everything designed will work on the production phase,” adds Simó. “It also allows jobs to be decentralised, rather than doing all works on site with limited space and resources. It can be used for steelworks, railings, machinery spaces, interior spaces, furniture, ceiling panels, windscreens and almost anything else.”

BYD deploys three devices for a laser scanning. Two long-range Faro Focus scanners capable of an accuracy down to 1mm from a distance up to 330m. The Faro Focus is able to measure nearly a million points every second. The other device is a more detailed Creaform Go! SCAN scanner with an accuracy of 0.05mm.

BYD deploys three devices for a laser scanning. Two long-range Faro Focus scanners capable of an accuracy down to 1mm from a distance up to 330m. The Faro Focus is able to measure nearly a million points every second. The other device is a more detailed Creaform Go! SCAN scanner with an accuracy of 0.05mm.

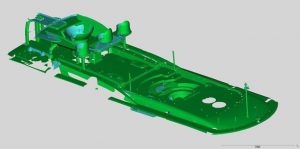

“We perform around 20 different scans from different positions, each of which acquires some 10.9 million points,” says Simó. “After processing, optimising and deleting non-usable data, as well as redundant points created by the cradle or the rigging, the hull of a 40m sailing yacht results in around 10 million points

“3D scanning is a hugely skilled job, with very precise setup required for accurate results. The equipment is portable, so the scan can be carried out wherever the boat lies, but the biggest investment is back in the office after the scan. Post processing is critical to obtaining a precise image and must be done by a professional.”

Scan times vary from 30 minutes for a 1m diameter propeller, to approximately eight hours for the complete hull of a 40m yacht. An interior cabin can be accurately scanned in around 45 minutes. The only limitation to the size of an object required to be scanned is the 330m range of the long-range Faro Focus scanner.

Professional grade 3D scanning solutions for metrology & engineering applications.