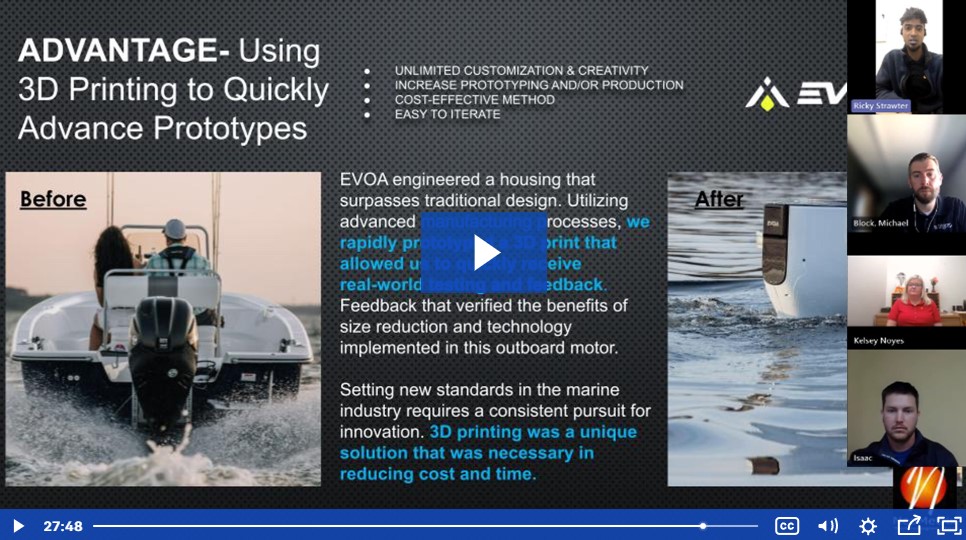

Revolutionizing EVOA EV Boat Motors with NeoMetrix 3D Printing Solutions

Discover the Unmatched Power and Performance of ADVANCED ELECTRIFIED PROPULSION and it's 3D Printing Development

Register for an on-demand webinar presentation hosted by our team at NeoMetrix where we meet with BigRep and EVOA representatives to learn more about a transformative 3D Printing application.

NeoMetrix Technologies, Inc. collaborated with a leading manufacturer of electric propulsion systems for recreational boats. The company aimed to develop high-performance 400+ horsepower EV boat motors for OEM applications. With a focus on innovation and customization, the project involved extensive prototyping over two years.

Before

After

THE PROBLEM

During the iteration process, the company faced challenges with traditional methods of prototyping. Previous systems were built into existing casings, limiting design flexibility and customization. As the project progressed, the need for rapid prototyping to produce custom parts quickly and facilitate faster design changes became evident.

TRADITIONAL METHOD

“Our team at EVOA has been developing an EV boat motor for OEM for the past 2 years. We got to a point in our development process where 3D Printing was the most efficient and high-quality process to get this to a final product stage, that’s where we contacted NeoMetrix.

Previously we were building these systems to existing casings that were not our original design. Another reason we went with 3D printing is the have a customized and unique design. If we’re developing our own product we might as well do it the right way!”

-Isaac Anderson, EVOA- Brand Development Expert

NEOMETRIX SOLUTION

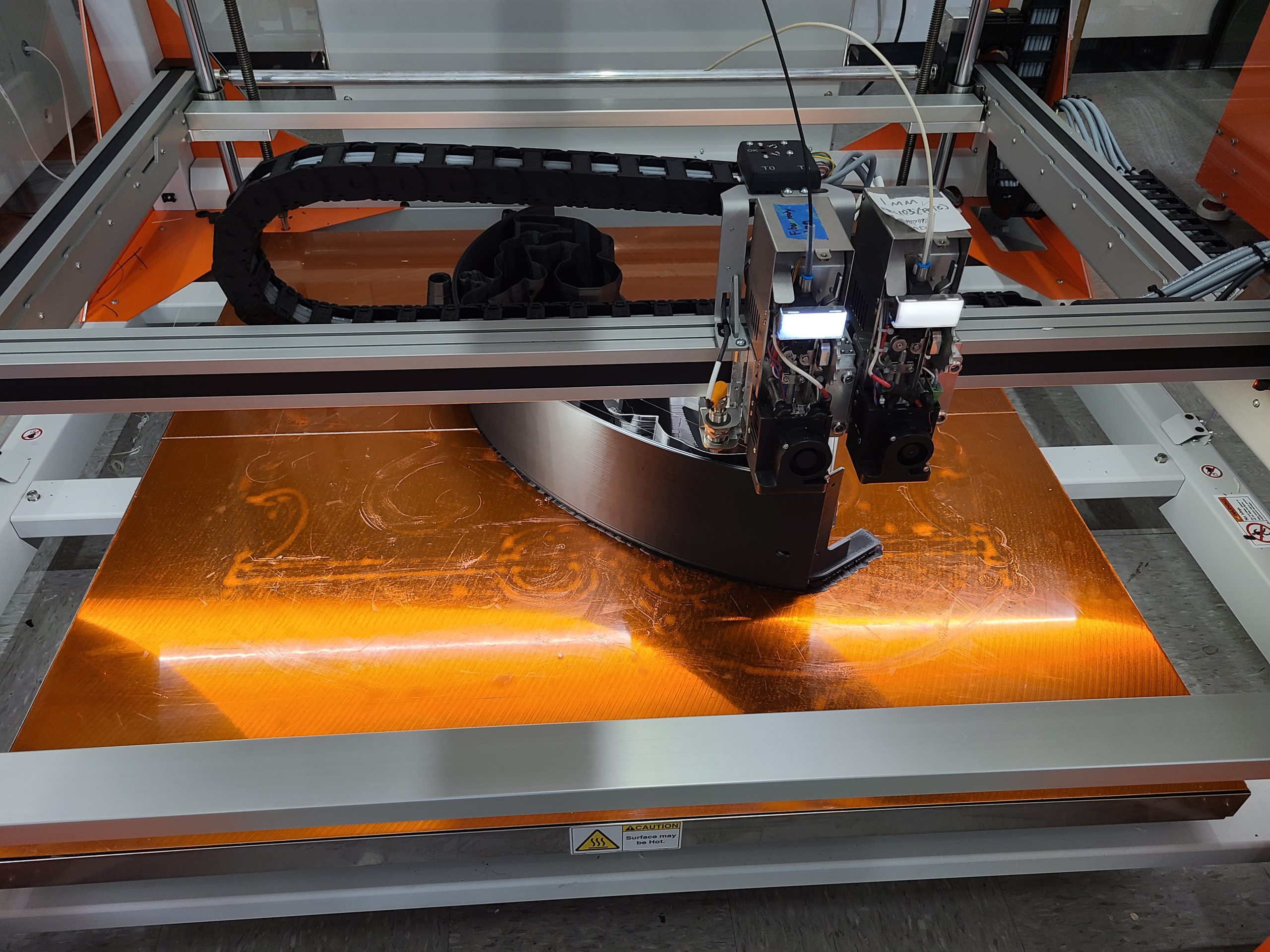

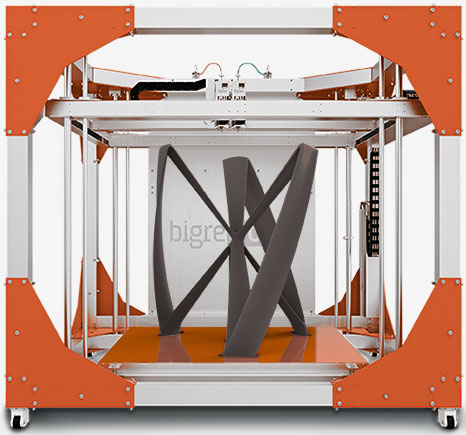

NeoMetrix introduced its ProHT 3D printing solution on the BigRep ONE to address the challenges faced by the manufacturer. The ProHT print enabled the stylization and customization of products while providing high-quality functionality. By leveraging 3D printing technology, the company aimed to streamline the prototyping process, reduce iteration cycles, and avoid doubling costs on prototyping.

Post Processing

The process involved a combination of fiberglass and dense plastics to create durable and functional parts. NeoMetrix experts collaborated closely with the manufacturer to design attachment points directly onto the 3D prints, ensuring seamless integration into the final product. Following printing, the parts underwent finishing processes at an auto body shop, including sandblasting, application of bondo, priming, painting, and clear coating.

The only marine company providing high-performance EV batteries:

- Industry-leading 800V- Advanced Architecture

- Best in Class Motor – Power/Weight ratio

- Highest Energy – Density @ 200WH/KG

- Fastest Level 2 Charging – 3-4 Hrs. Activity Time

- On Board Telematics

NEOMETRIX ADVANTAGE

- Customization: 3D printing allowed for the creation of highly customized parts tailored to the specific needs of the project.

- Speed: Rapid prototyping significantly accelerated the product development timeline, reducing time-to-market for the EV boat motors.

- Cost-Effectiveness: By minimizing the need for traditional thermoforming methods, 3D printing helped optimize costs and resources.

- Iterative Design: The iterative design process facilitated by 3D printing enabled the manufacturer to iterate quickly on design changes, leading to improved product iterations and overall performance.

ON-DEMAND WEBINAR