3D Printing plays a big role in the development process of

electronics and computers.

Design Quality of Hardware for Electronics

One of our clients wanted to print a CPU enclosure on their consumer 3D printer at home, but the results were not good due to warping and many unsuccessful prints. We worked with them and convinced them that they should use an industrial-grade device instead of one designed for consumers because of how differently it performs in different environments – like when exposed directly against heat or heavy vibrations during printing!

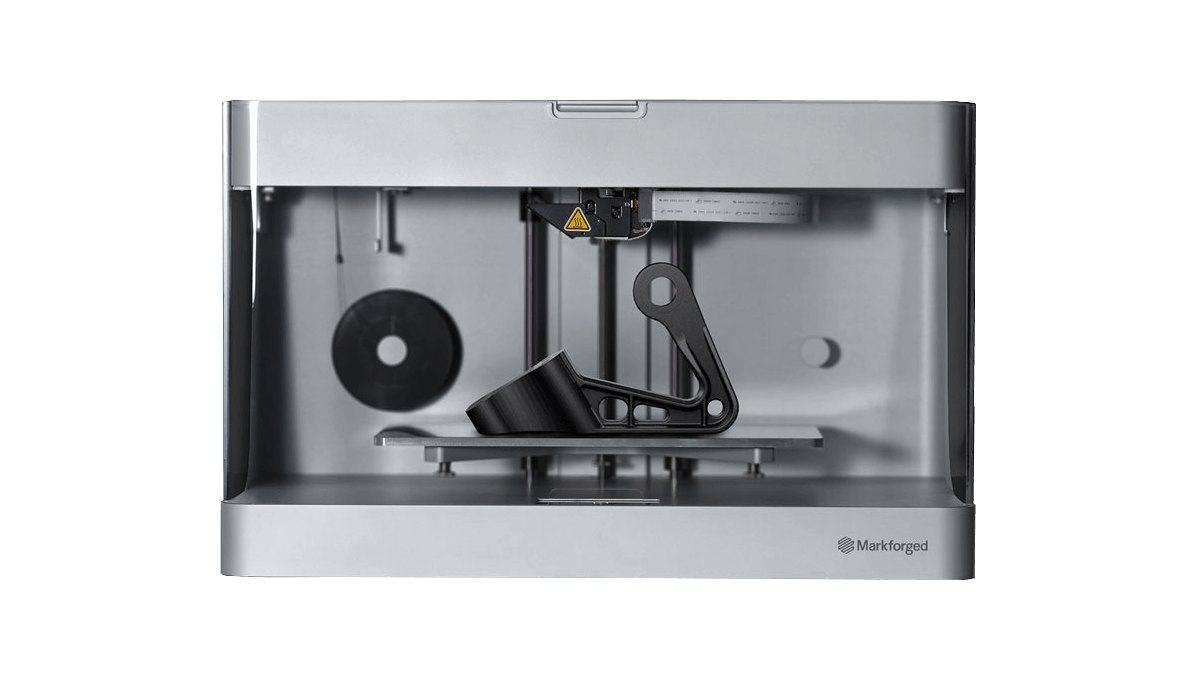

Markforged Mark Two 3D printer has the ideal solutions to produce this type of part or hardware. It’s easy and quick, with nearly perfect surfaces! Mounting holes are printed with high-accuracy allowing screws, bolts, and nuts to be used for assembly. Onyx material was used has been proven to be an all-around high perfmance material

Mark Two

Industrial vs Consumer 3D Printers

Main Features

Print Size

High-Accuracy

Build Environment Temp Control

Extrusion Temperatures

Engineering-grade Materials

Industrial 3D Printers

up to 1m3(or larger)

X

X

up to 450 °C

X

Consumer 3D Printers

250 x 250 x 250 mm (or less)

_

_

up to 260-280 °C

_

3D Printing and Injection Molding Can Work Together

Mass production of computer parts is a standard practice that has been around for many years. However- before the traditional injection molding stage, it’s important to test models in order find out if they will fit well and create an efficient design which can be 3D printed during the Rapid Prototyping process.

The injection process is designed to melt the raw plastic and guide it into a mold. The whole action can be repeated very fast; this takes approximately 30-90 seconds depending on size of part. The part is ejected, and then it’s dispensed on a conveyor belt or in the holding container. Usually injection-molded parts are ready to use right away without any post processing needed at all!

Now, thanks to advances in 3D printing materials and a new form of low-run injection molding that can produce molds suitable for 100 parts or less at an affordable price point. This is possible because traditional methods were too expensive when producing such small volumes; before this development it would have been economical only if there was sufficient demand from customers who required many copies be made simultaneously – which doesn’t happen often!

Drive Business While Saving Time & Expenses

The goal with integrating 3D Printing into many manufacturing processes is the quality of the final product and the repeatability of the process. To yield the full benefits of the process, the designer must meet certain design guidelines with their 3D equipment. Get in touch with us to get started with Rapid Prototyping services today!