Are you looking for a solution to improve the precision and repeatability of your manufacturing processes?

Some of the top benefits of investing in 3D Printing are designing and implementing specific production tools that promote repeatability, reduce production time, and increase the efficiency of the entire creative process.

Having your own printer and 3D printing jigs and fixtures in-house provides easy access to produce parts specifically designed to support or hold in place the piece to be machined or examined, ensuring the relative positioning of the object with respect to the processing tool (typically cutting) by means of a guide. We use innovative materials with excellent thermomechanical properties and chemical resistance to provide the stiffness necessary to avoid any kind of deformation over a wide range of conditions.

Assembly Jig

Fast and easy to customize, 3D printed assembly jigs ensure correct alignment, attachment, and securing of workpieces.

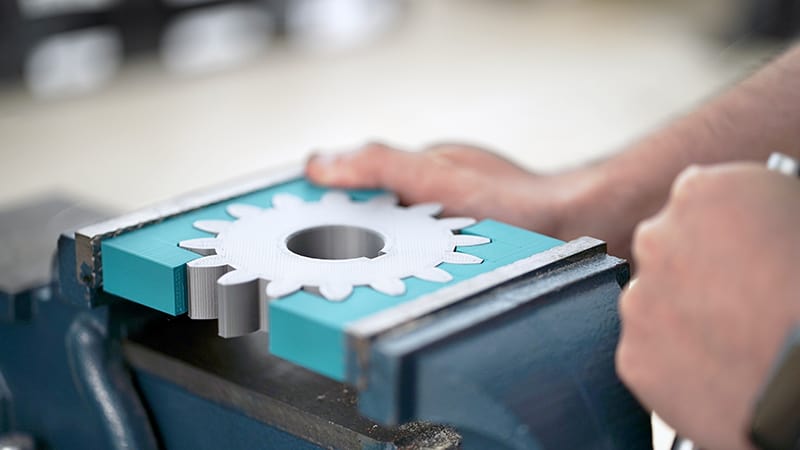

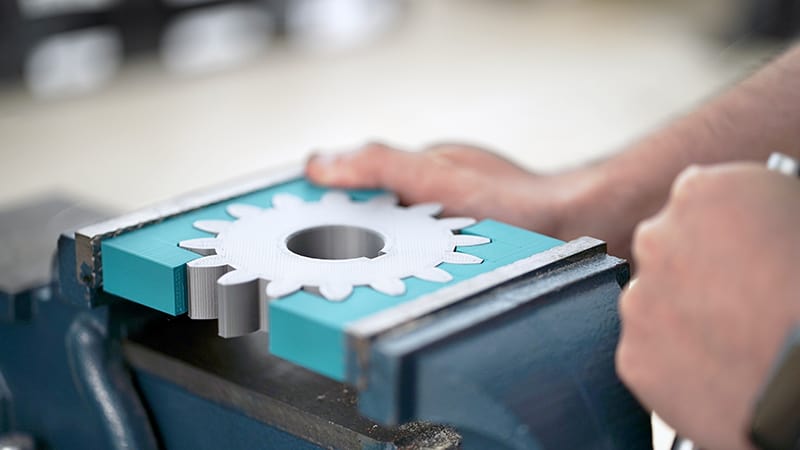

Soft Jaw

3D printed soft jaws perfectly hold workpieces too complex for standard vice jaws and can be produced faster and cheaper than standard methods.

Tool Holders and Fitted Compartments

Among their many 3D printing use cases, WAT also produces custom tool holders to streamline workspaces.

Handheld Alignment Jig

Ford uses lightweight 3D printed alignment jigs to correctly place logos and decals on their cars.

Welding and Milling Fixtures

Produced in a fraction of the time, 3D printed fixtures can greatly improve the quality of welding and milling jobs.

Inspection Fixture

Ford uses 3D printed inspection fixtures to check that the fit between the car body and door achieves acceptable tolerances.

When direct production is not possible, outsourcing 3D printing can be used to create elements that support traditional manufacturing methods. We offer 3D printing services that allow for the production of finished and functional parts with the same level of accuracy and repeatability as any production technology. Our design process for 3D printing is primarily focused on reducing production times and using engineering-grade materials, allowing for greater design freedom and fast turn-around times.

We also have the capability to assist companies of all sizes with purchasing a machine for their business or facility to have all parts produced in-house and on demand.

Partner with NeoMetrix Technologies, Inc. to improve the precision and repeatability of your manufacturing processes, reduce costs and lead times for customers, and enjoy the benefits of 3D printing technology. Trusted 3D printing of durable and engineering-grade materials allows for the creation of tools that can improve manufacturing and repeatability. Produce numerous forms of assembly fixtures and jigs for a fraction of the cost, time, and resources compared to traditional manufacturing.

Contact us today to learn more about our solutions and services.

Original Article: https://bigrep.com/applications/jigs-and-fixtures/?utm_source=google&utm_medium=cpc&utm_campaign=NA-Appl&utm_id=12798895129&utm_term=Jigs-Fixtures&gad=1&gclid=CjwKCAjw0ZiiBhBKEiwA4PT9z7a5LEXGojE9mkFldOSe7cuDBwhjX8PVBHHwN1oLyANwwzY0B1fUkRoCK38QAvD_BwE

Check Out Our Available 3D Printing Equipment