| INTELLIGENT ADDITIVE MANUFACTURING SYSTEMS |

Infinite Possibilities

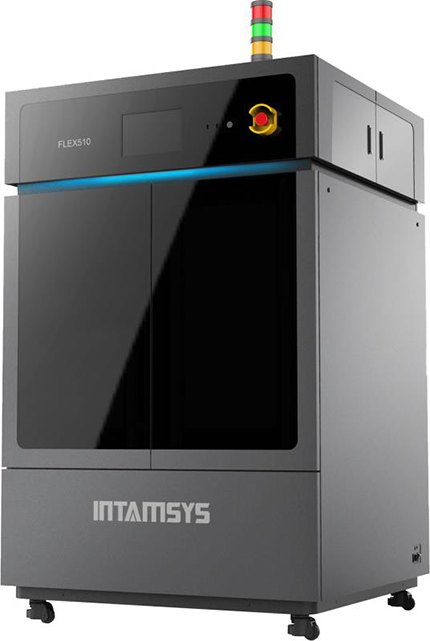

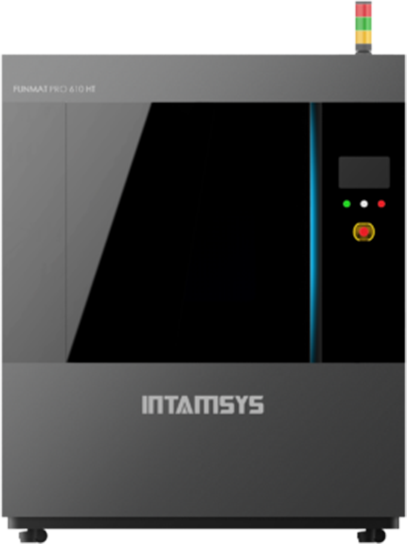

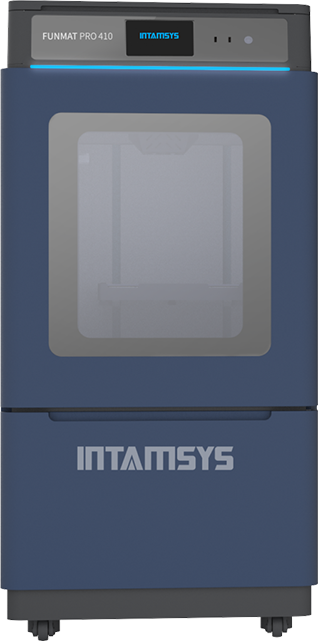

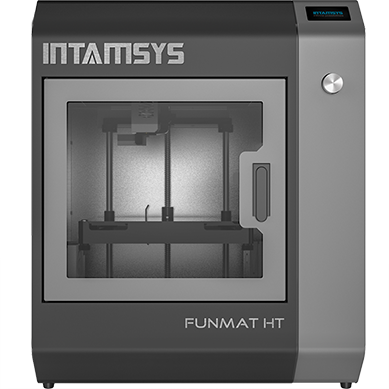

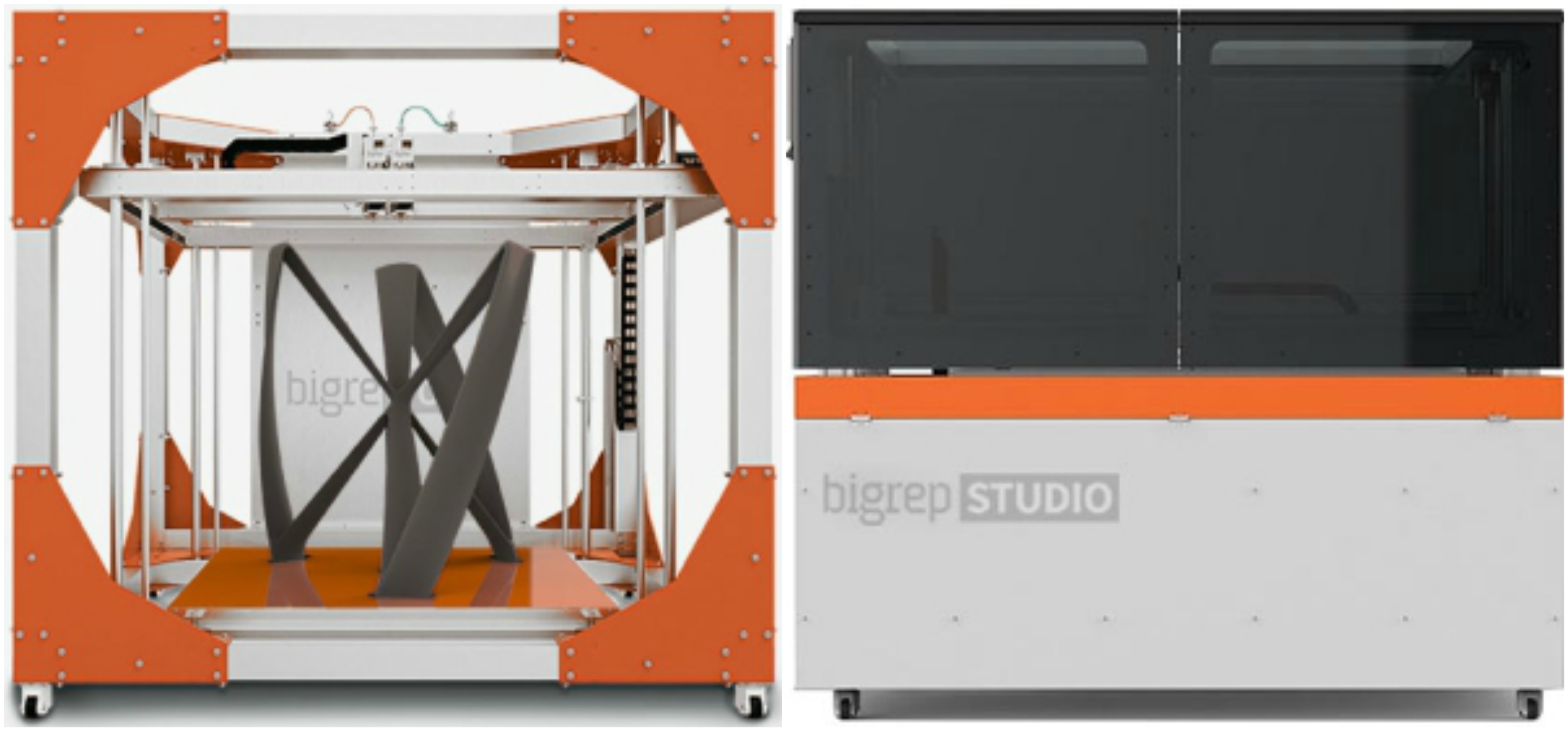

Our newest addition to available 3D printing equipment, INTAMSYS, now has 4 different models that are suited and optimized for up to thousands of industries.

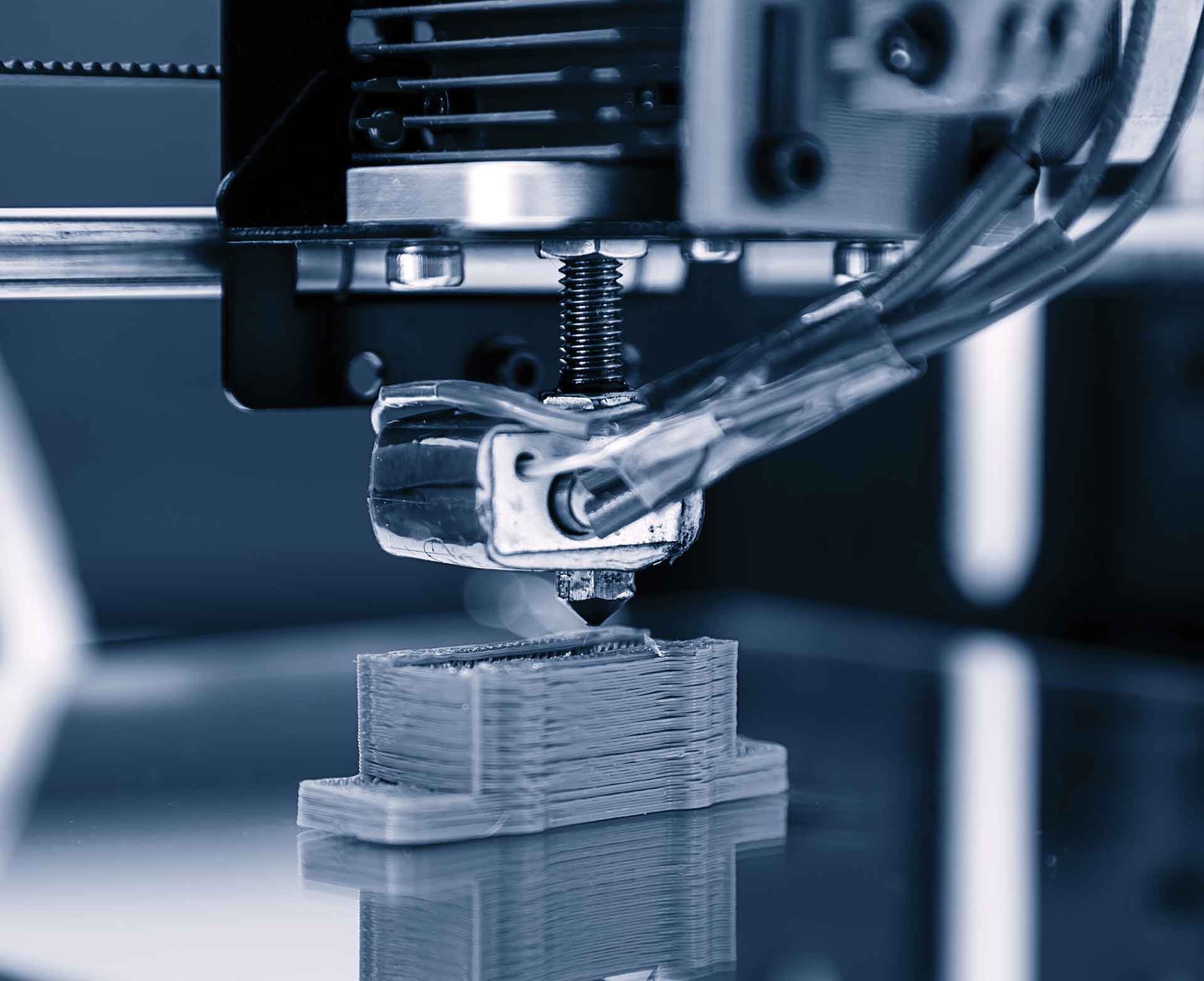

Print using a wide range of high performance polymers & functional engineering materials that have the ability to meet many of today’s extreme environments such as, chemical, impact, thermal, and electrical plus more!

Professional & Industrial 3D Printers starting from $7,500! Learn about the benefits to automate, save material, and save cost by having the INTAMSYS Complete 3D Printing Systems.

High Performance Funtional 3D Printers & Materials Now Available through NeoMetrix!

- ABS

- Nylon

- PC

- PPSU

- ULTEM

- PEEK

- ABS

- Nylon

- PC

- PPSU

- ULTEM

- PEEK

- PEEK

- PEEK-CF

- PEKK

- ULTEM

- PPSU

- PA

- PA-CF

- PC

- ABS

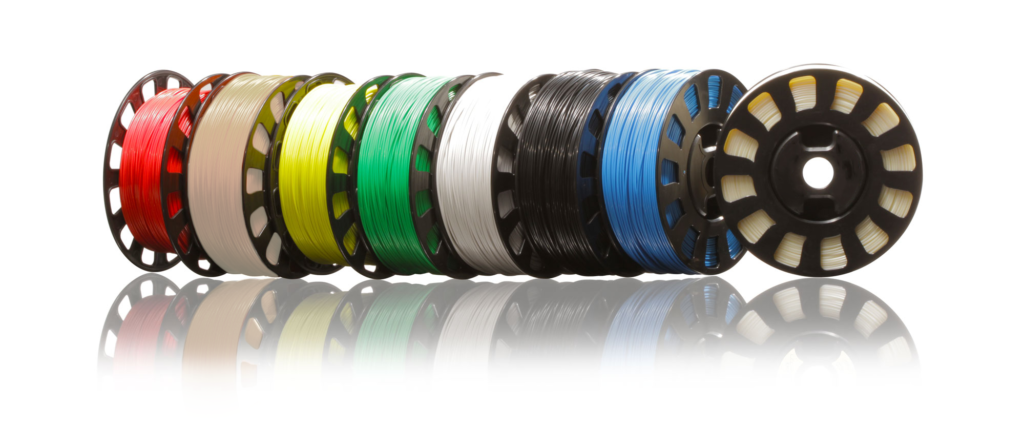

INTAMSYS High-Performance Polymer Materials

View the wide range of 3D Printing material available to meet the demands of any application or environment.

PEEK

PEEK (Polyetheretherketone) is considered as one of the world’s highest performing engineering thermoplastics, offering exceptional chemical resistance and excellent mechanical properties at high temperatures.

Main applications of PEEK in additive manufacturing include metal-replacement, functional prototyping, and end-use parts for industries like aerospace, automotive, oil and gas, medical, dental and research.

PEEK-CF

PEKK

PEEK (Polyetheretherketone) is considered as one of the world’s highest performing engineering thermoplastics, offering exceptional chemical resistance and excellent mechanical properties at high temperatures.

Main applications of PEEK in additive manufacturing include metal-replacement, functional prototyping, and end-use parts for industries like aerospace, automotive, oil and gas, medical, dental and research.

ULTEM

ULTEM™ 1010 resin is an amorphous, transparent polyetherimide plastic offering enhanced flow and a glass transition temperature (Tg) of 215°C.

Supported 3D Printers:

Supported Filament:

Download Data Sheet:

ULTEM™ 9085 resin offers the ability to create parts with excellent properties at elevated temperatures due to a glass transition temperature (Tg) of 186°C.

PPSU

PPSU is available in FDA compliant grades. Please ask your Curbell Plastics representative for more specific information.