Sonic Communications, a global leader in specialized equipment for police, military, government, and industrial sectors, has seamlessly integrated 3D printing into their operations, revolutionizing their product development.

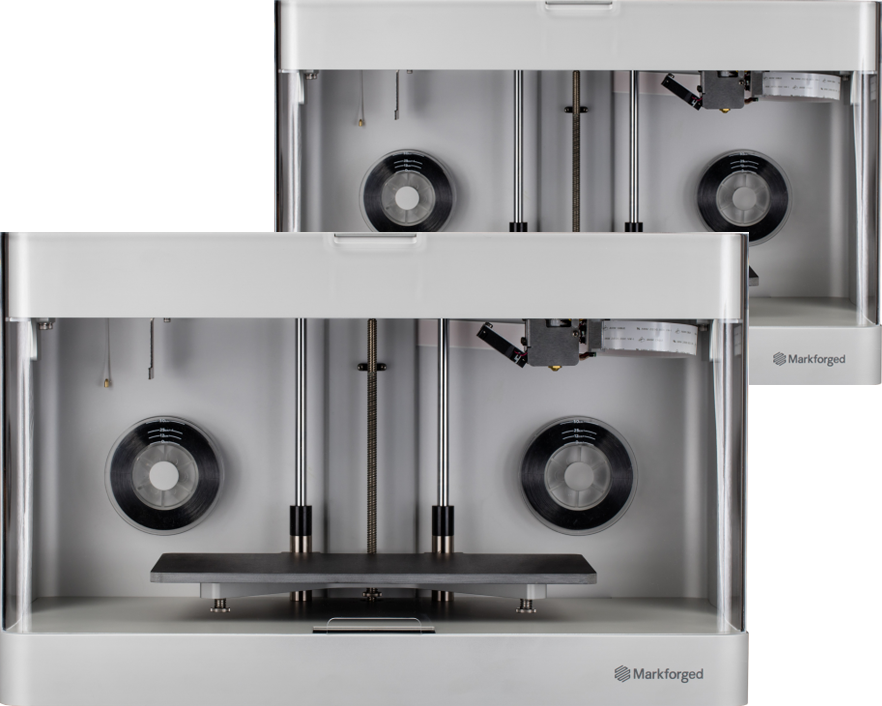

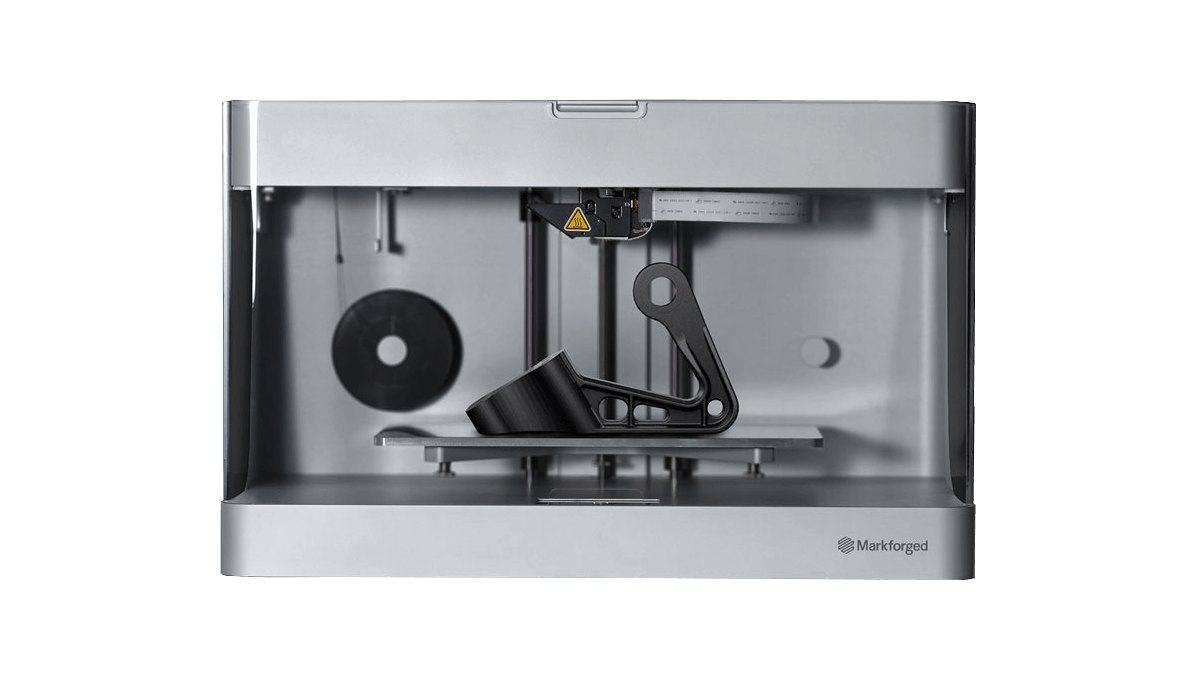

With over four decades of experience, Sonic Communications, based in Birmingham, UK, has embraced the power of 3D printing with Markforged. Having acquired eleven Markforged printers in 2022, Sonic has experienced a transformative additive revolution. Their investment has not only saved time and increased efficiency but has elevated their creativity and customization capabilities.

Increased Efficiency & High-Accuracy

Prototype &

End-Use Parts

Engineering-Grade Materials

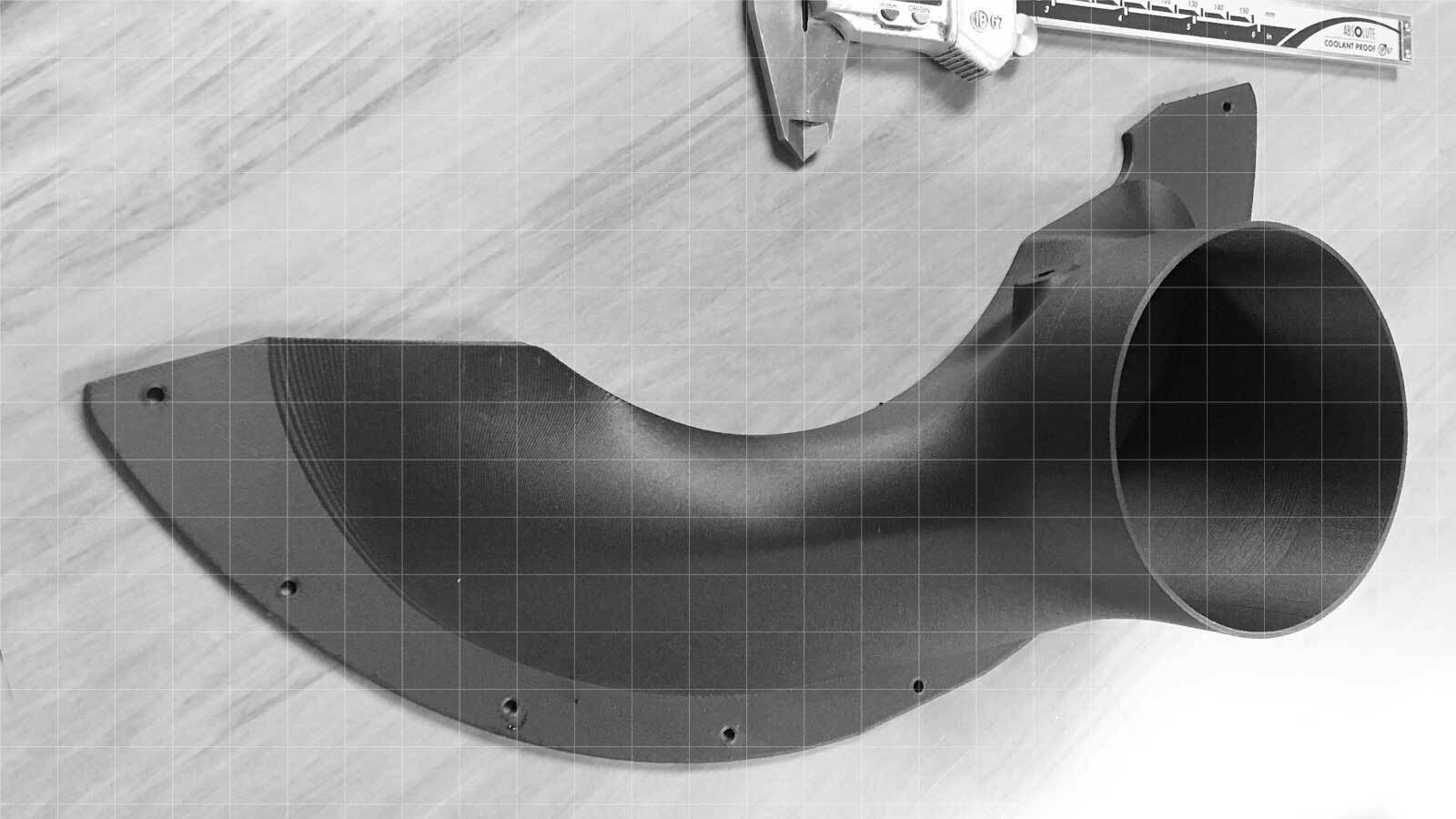

Mark McDonald from Sonic Communications emphasizes that Markforged has empowered them to break free from the constraints of traditional manufacturing methods. No longer confined to the limitations of CNC milling or injection molding, Sonic now pioneers designs with curves and textures that are more ergonomic and aesthetically pleasing. For instance, their EHIU3 application box for law enforcement, printed in Onyx, showcases the advantages of lighter, more user-friendly, and customizable 3D-printed parts.

Markforged’s Onyx materials have facilitated Bluetooth transmission, a feat unattainable with machined metal. This innovation has significantly enhanced audio accessories, positioning Sonic Communications as a leader in the industry. McDonald highlights that products that used to take up to a year to reach main production can now be achieved in just three months, thanks to Markforged.

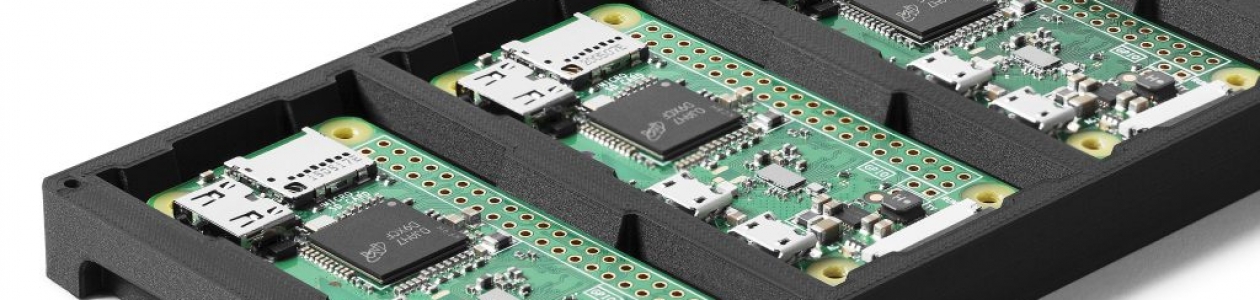

Beyond product innovation, Markforged offers Sonic the flexibility to navigate supply chain challenges. By modifying designs to accommodate available electronic components during chip shortages, Sonic ensures a quicker turnaround time for their customers. The ability to create customized fits for electronic components sets Markforged apart, allowing Sonic to deliver final products in weeks instead of waiting for standard components.

Go from design to final product in a quarter of the time it would have taken to create the same product using machine shops and tools.

In addition to streamlining production, Markforged has revolutionized Sonic’s sales process. Potential customers can discuss their requirements, and with Markforged’s rapid prototyping capabilities, Sonic can provide a physical prototype during the meeting. This hands-on approach not only builds momentum and interest but also allows Sonic to showcase the possibilities and passion they bring to each project.

In just six months, Markforged has accelerated Sonic’s product development, enabling them to go from design to final product in a fraction of the time. Sonic’s commitment to innovation is evident as they run their fleet of Markforged printers 24/7 to meet the growing demand for their cutting-edge, customized products.

The time is now to join Sonic Communications in embracing the speed, agility, and creativity that 3D printing with Markforged brings. Whether you are in law enforcement, military, government, or any industrial sector, this technology can turn your ideas into reality, providing unmatched flexibility and efficiency in product development.

Original article: https://markforged.com/resources/case-studies/sonic-communications

Discover a Faster Route for your business

with a Markforged 3D Printer!

SPEAK WITH AN EXPERT

There’s no better time than now to embark on your 3D printing journey with NeoMetrix or acquire a Markforged desktop Mark Two or industrial X7 3D Printer.