Mining for Oil, Gas, and Resources

Mining industries face unique challenges that demand cutting-edge solutions for inspection, maintenance, and manufacturing.

At NeoMetrix Technologies, we offer top-tier 3D Scanners and 3D Printers, along with expert reverse engineering and additive manufacturing services to address these needs.

The mining industry thrives on precise information regarding mineral resources, tunnel orientations, equipment conditions, and safety measures.

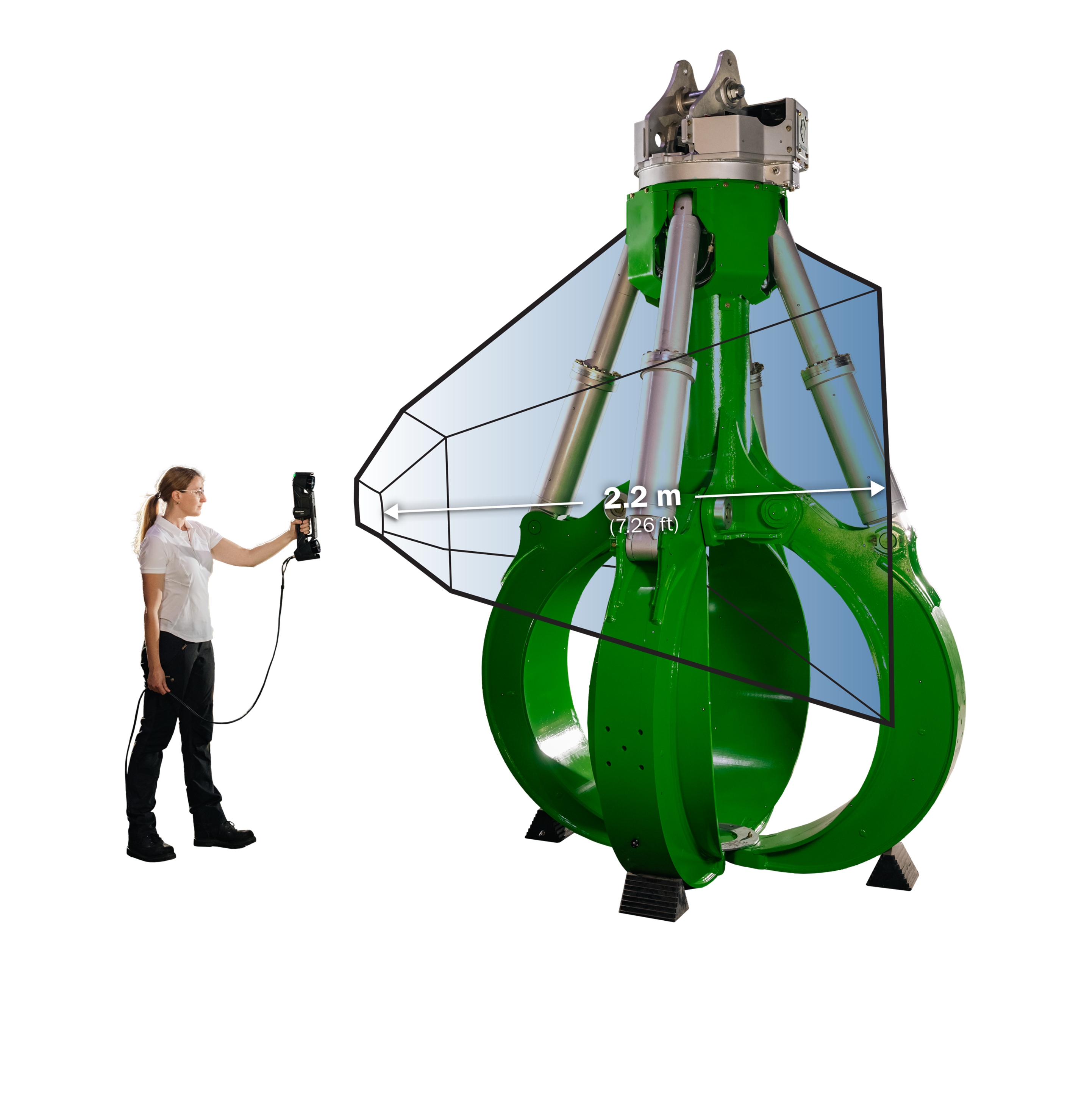

3D scanning technology is revolutionizing modern mining operations by providing faster and higher-resolution data than traditional methods. This powerful tool addresses key challenges, such as underground mapping, managing hazardous sites, and minimizing equipment downtime, thereby enhancing operational efficiency and meeting tight project timelines.

3D SCAN-TO-CAD SOLUTIONS

REVERSE ENGINEERING & 3D MODELING

INSPECTION & QUALITY CONTROL

Applications in Mining & Heavy Industies

- Prototyping: Test-fit designs before final production.

Functional Replacement Parts: Ensure durability and reliability. - Jigs, Fixtures, and Tooling: Enhance and speed up manufacturing processes.

- Semi-Structural Components: Produce brackets, clips, and similar parts.

- Heavy-Duty and Electrical Enclosures: Create durable housing solutions.velop robust energy storage solutions.

- Rugged Enclosures: Protect sensitive equipment.

- Mine Site Weather Stations: Produce reliable weather monitoring equipment.

- Pipes: Inspect and analyze pipeline integrity to prevent failures and ensure continuous operation.

- Heavy-Duty Machinery: Utilize 3D scanning to assess wear and tear, optimize maintenance schedules, and extend the lifespan of machinery.

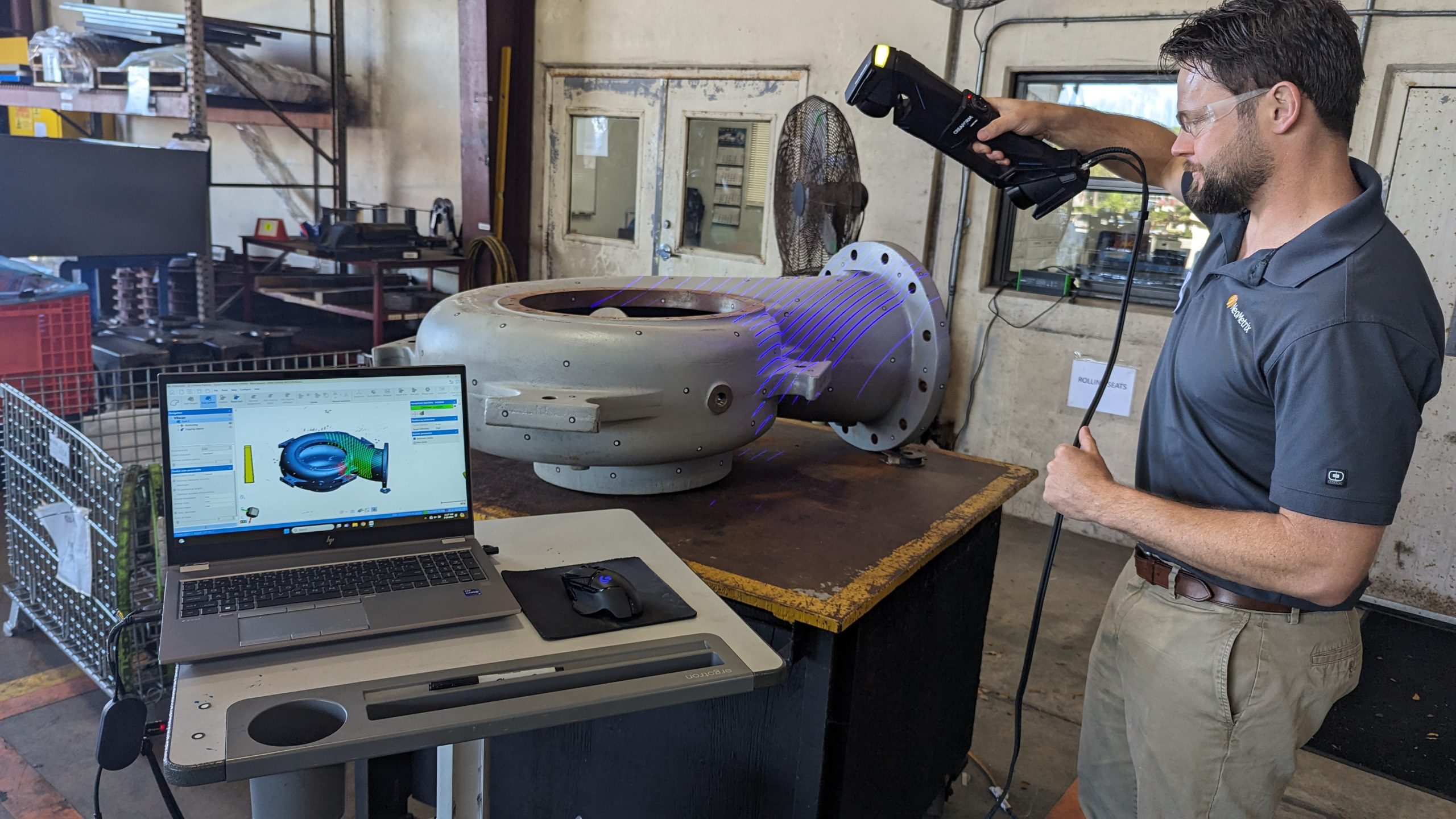

- Volutes and Pumps: Reverse engineer complex components to create accurate, high-quality replacements or upgrades.

Risk Management of Aging Equipment and Infrastructure

As much of the mining infrastructure dates back to the 60s and 70s, it faces significant aging issues. Given the impossibility of repairing all machinery as damages occur, asset owners must manage the risk associated with deteriorating infrastructure.

Risk management in the context of aging infrastructure involves tracking and monitoring damages over time due to limited resources for immediate repairs. Digitizing measurements and comparing data between maintenance rounds allows service companies to prioritize repairs based on damage severity.

Special paints, process modifications, and welded alloys can be used to limit the progression of damage, but regular inspections are still necessary. 3D scanning technology plays a crucial role in this process by detecting even the smallest changes in defect conditions and dimensions, providing traceable, accurate, user-independent, and noise-free data with the Damage Monitoring Module.

Produce Heavy-Duty Parts with BigRep 3D Printers

BigRep 3D Printers excel in producing large-scale, high-precision parts that meet the demanding requirements of the mining industries. From functional prototypes to durable tooling, BigRep printers provide the versatility and reliability needed for large and modern industrial applications.

A BigRep ONE machine was donated to a university for the testing of the load capacity of a carabiner made from BigRep PLA. The team calculated it could lift up to 1000 kg (2204.62 lbs). They customized a 3D model from ddf3d.com and printed it in eight hours with 25% infill and a 6 mm wall thickness.

In collaboration with MotionLab in Berlin-Kreuzberg, which provided the space and crane, the goal was to lift the printer 15 cm. Padding was placed beneath each corner for safety, and all involved staff wore helmets to ensure a safe operation.

The BigRep PLA carabiner lifted the 733.9 lbs machine, then the team added more weight to the printer to make it 1117.74367 lbs (507 kg) and it held, comfortably. – MotionLab

SOLUTIONS IN ACTION

How NeoMetrix Utilized 3D Scanning to Revolutionize Complex Part Manufacturing

Transforming Complex Volute Manufacturing with 3D Scanning

3D Scanning for Mining Applications

Download this free EBook to discover how 3D scanning is helping mining companies locate and access critical resources, maintain shafts and machinery, manage assets and improve safety.