The aerospace industry, responsible for the safe transit of millions of passengers and countless tons of cargo daily, is held to some of the highest standards in manufacturing. These standards are crucial given the challenging operating conditions and the need for reliable, long-lasting performance of aerospace vehicles. However, maintaining these standards poses significant challenges, particularly when it comes to inspecting and replacing parts that may lack detailed documentation.

The Role of 3D Scanning in Aerospace

As aerospace vehicles age, the necessity for precise and comprehensive inspections becomes paramount. Traditional methods often fall short in terms of accuracy and efficiency. This is where 3D scanning technology steps in, offering a solution that not only meets but exceeds the industry’s stringent demands. Fast, accurate 3D scanning simplifies and streamlines part development, reverse engineering, inspection, and other critical applications. Download the latest eBook whitepaper by Oqton, who featured our aerospace experience and solutions.

In our featured comprehensive eBook, “3D Scanning Applications in Aerospace,” we explore real-world examples showcasing how 3D scanning is revolutionizing the industry. The eBook explores workflows and case studies where NeoMetrix and Oqton solutions have been successfully implemented, demonstrating tangible improvements in efficiency, accuracy, and cost-effectiveness.

Explore the buzz on the latest HandySCAN Black+ Elite 3D Scanner from Creaform!

NeoMetrix and Oqton: Pioneering 3D Scanning and Reverse Engineering

At the forefront of this technological advancement is NeoMetrix, a leader in optimizing 3D scanning technology. By leveraging the innovative solutions from Oqton, NeoMetrix has become a key player in transforming aerospace manufacturing and maintenance workflows through services and equipment.

Key Benefits of 3D Scanning in Aerospace:

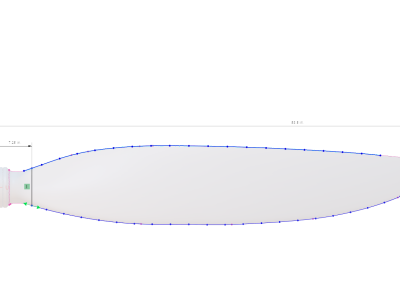

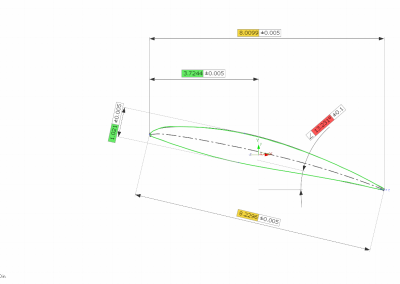

- Precision and Accuracy: 3D scanning provides high-resolution data that captures every detail of aerospace components, ensuring parts are manufactured to exact specifications.

- Efficiency: The speed of 3D scanning accelerates the inspection process, reducing downtime and increasing productivity.

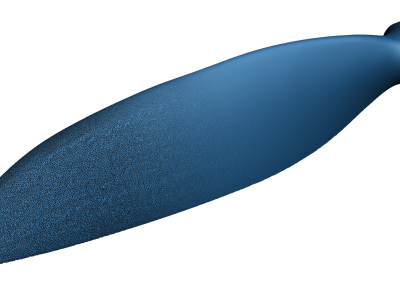

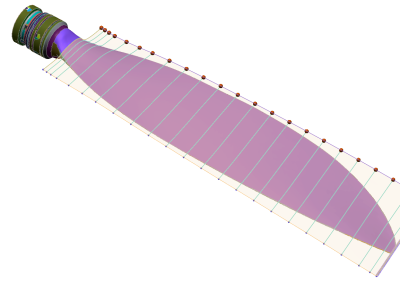

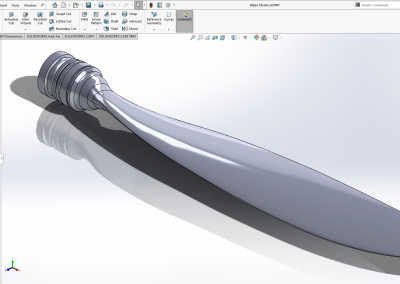

- Reverse Engineering: For parts that lack documentation, 3D scanning allows for accurate digital replication, facilitating the creation of parametric models for manufacturing and repair.

- Quality Assurance: Continuous, detailed inspections with 3D scanning ensure that all components meet rigorous aerospace standards, enhancing overall safety and reliability.

Real-World Applications and Case Studies

- Streamlined Part Development: How 3D scanning expedites the design and prototyping stages, leading to faster product development cycles.

- Enhanced Maintenance Procedures: The role of 3D scanning in predictive maintenance, helping to identify potential issues before they become critical.

- Legacy Part Reproduction: The use of reverse engineering to recreate obsolete or undocumented parts, ensuring the longevity of aerospace fleets.

Explore Our Range of Solutions

For aerospace innovators and manufacturers seeking to elevate their operations with cutting-edge technology, NeoMetrix offers a comprehensive suite of 3D scanning and reverse engineering solutions.

Contact us today to learn more about how our partnership with Oqton can transform your manufacturing and maintenance processes. Embrace the future of aerospace with NeoMetrix, and ensure your operations meet the highest standards of precision, quality, and efficiency.