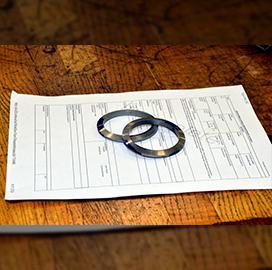

A 3D-printed anti-ice gasket meant to work with the TF33-P103 aircraft engine has been manufactured by the Tinker Air Force Base’s Oklahoma City Air Logistics Complex.

The Reverse Engineering and Critical Tooling Lab has been able to digitally engineer and print 3D anti-ice gaskets, while the 76th Propulsion Maintenance Group conducted engine acceptance tests for the components, the U.S. Air Force said Monday.

USAF noted the manufacturing process decreased administrative lead time from a range of 120 to 136 days to a period of 14 to 21 days. OC-ALC aims to address the shortage of anti-ice gaskets through the additive printing project.

Photo of B-52 aircraft in mid-flight.

The TF33-P103 engine is designed to power E-3 Airborne Warning and Control Systems, B-52 Stratofortress aircraft units and E-8 Joint Surveillance Target Attack Radar Systems.

Source: https://www.executivegov.com/2020/08/tinker-afb-unveils-3d-printing-project-for-aircraft-engine-component/