Manufacturing has never been limited by ideas.

It’s limited by bad data, disconnected tools, and decisions made too late in the process.

That’s why the most effective engineering teams today don’t treat 3D scanning and 3D printing as separate technologies. They treat them as one continuous system.

At NeoMetrix, that’s exactly how we operate — and it’s why companies come to us when accuracy, performance, and repeatability actually matter.

Your Home for 3D Solutions

3D Scanning: Where Engineering Truth Begins

Every part tells the truth — if you measure it correctly.

With the release of the Creaform HandySCAN EVO, high-accuracy 3D scanning has become even more accessible for real engineering workflows:

-

High-resolution, metrology-grade data without rigid setups

-

Faster capture for complex, reflective, or organic geometry

-

Reliable scan data for reverse engineering, inspection, and validation

-

A direct bridge from physical part → CAD → manufacturing

The EVO isn’t just faster. It reduces friction between what exists and what gets designed next. And that difference compounds across every downstream decision.

Real Industry Applications

Featuring solutions for aircraft tooling, automotive components, injection molds, jigs & fixtures, and legacy part restoration.

Scan → CAD → Validation → Additive Manufacturing → Final Part

Additive Manufacturing: When 3D Printing Becomes Production

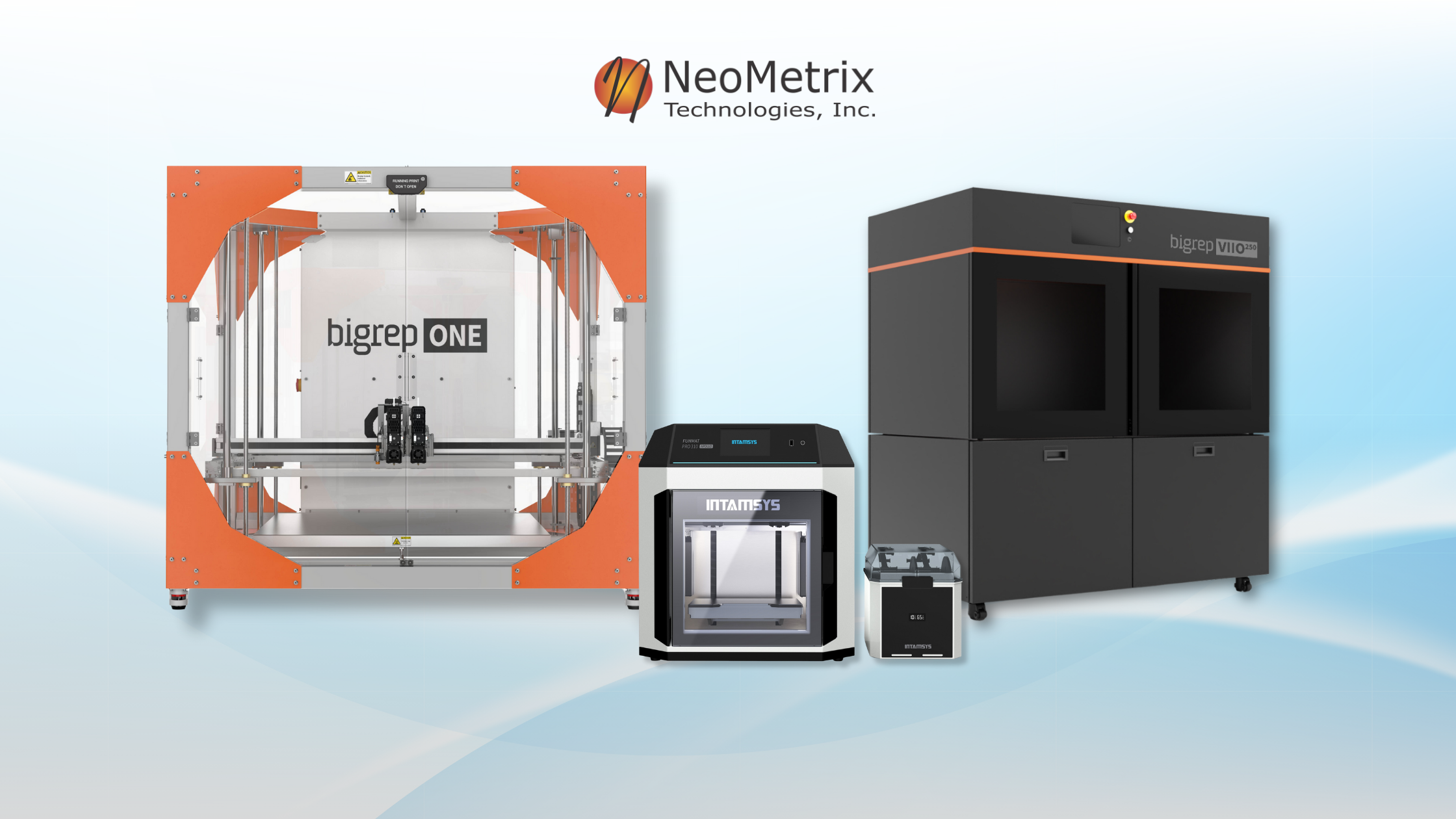

3D printing only delivers value when materials, scale, and process align with engineering intent. That’s why our additive manufacturing portfolio spans far beyond prototyping.

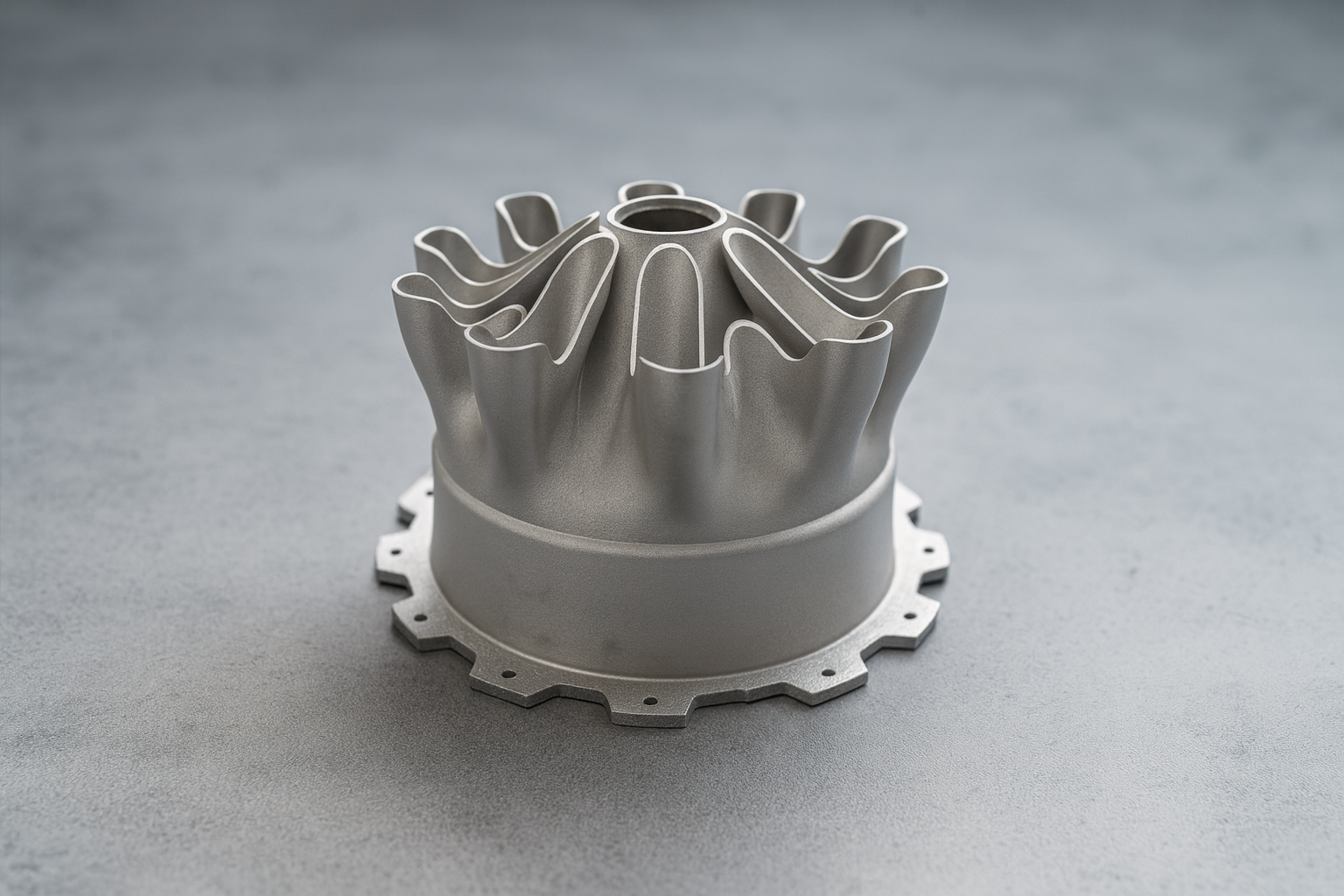

What’s New at NeoMetrix: 3D Print Titanium, Stainless Steel (316L), Aluminum, and Copper Alloys

The latest MASTREX platforms expand what’s possible with:

-

Metal additive manufacturing for tooling, fixtures, and functional components

-

Ceramic 3D printing for heat-resistant, electrically insulating, and chemically stable applications

-

Systems designed for engineering environments, not demo rooms

Combined with our polymer and large-format platforms, we support:

-

Functional prototypes that behave like end-use parts

-

Low-volume production without tooling delays

-

Large, strong components that traditional manufacturing struggles to deliver quickly

This is additive manufacturing used intentionally — not experimentally.

Why Scanning + Printing Together Matters

Most companies sell scanners. Others sell printers. Very few understand how measurement accuracy affects manufacturing success. That gap is where projects slow down, budgets inflate, and confidence erodes.

Because when scanning and printing are disconnected:

-

Scan data isn’t optimized for manufacturing tolerances

-

Printed parts don’t match real-world geometry

-

Validation happens too late

-

Iterations multiply

When they’re integrated:

-

Parts fit the first time

-

Designs are validated digitally before material is consumed

-

Decisions are made earlier — when they’re cheaper

Equipment. Services. Engineering Support.

-

Engineering-grade 3D scanning services

-

Industrial additive manufacturing services

-

Equipment sales with application-driven guidance

-

Workflow consulting to ensure long-term success

Our mission at NeoMetrix is to reduce uncertainty in engineering decisions.

Open House & Demos at NeoMetrix – February 19th, Lake Mary, FL

3D Scanning & Inspection: Featuring live demonstrations of portable scanners like the HandySCAN EVO and MetraSCAN 3D, used for dimensional inspection, reverse engineering, and scan-to-cad processes. Learn More

Additive Manufacturing: Showcasing functional parts printed in carbon fiber-reinforced nylon, ULTEM™, PEEK, PEKK, ESD-safe, and bio-compatible materials, across a range of applications from prototyping to production.

Reverse Engineering & CAD Modeling: Visual workflows demonstrating how raw 3D scan data is transformed into high-accuracy parametric models using industry-trusted platforms like Geomagic Design X, Control X, and Creaform.OS.

Want to talk through a real application?

Whether you’re evaluating scanning, additive manufacturing, or how they fit together: Let’s have a technical conversation.