Check out Markforged ESD

The Best 3D Printing Solution for Electronic Applications Request More Info The Best 3D Printing Solution for Electronic Applications

The Best 3D Printing Solution for Electronic Applications

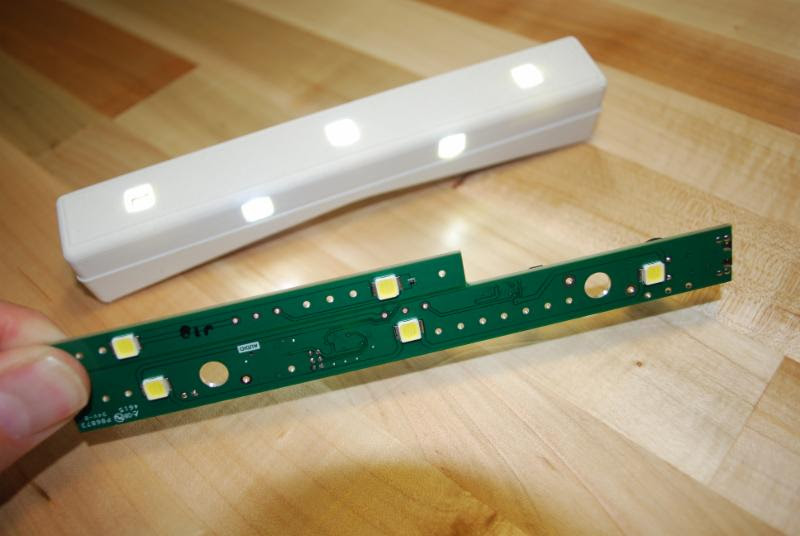

In the years since 3D printing really emerged as a viable technology, we’ve seen it applied to all sorts of different projects and purposes. Often enough, it’s the fun stuff that tends to make headlines: printing character figurines, turning digital sculptures into real ones, and so on. But 3D printing has also been put to excellent use in industries: prototyping construction projects, fabricating medical equipment, and as noted in our write-up asking ‘Should Designers and Developers Take Note of 3D Printing’, PCB design. For those who might not be aware of the term, PCBs are printed circuit boards. They are small pieces of hardware, intricately designed with different components that receive and transmit electronic signals within our devices. PCBs are at the core of so many of the electronic items we rely on today, and in the past they’ve been the products of fairly ordinary manufacturing processes. Now however, we are beginning to hear more about functioning PCBs being produced via 3D printing. This matters for a few important reasons: Keeping Up with Digital Design To some extent, 3D printing increasingly appears to be a necessity if manufacturing is to keep up with the complexity of PCB design. Altium’s feature on 3D measuring in PCB design makes clear that today, the software that goes into the rendering of these projects allows for great intricacy and complexity. In order to match the needs of today’s electronics, PCBs are designed with multiple layers, stacked components, and far more connections than in the past. Now, it is still possible to take a 3D design such as this and produce it as a functioning PCB by traditional means. But 3D printing simplifies the process of turning a complex, modern rendering into a real object. It should, in short, help manufacturing to keep up with design.