Scientific Research and Education – Innovation is Key

Universities and research institutions constantly seek new ways to push the boundaries of knowledge, and 3D printing has emerged as an essential tool in this pursuit. Large-scale additive manufacturing (AM) is revolutionizing how experiments are conducted, enabling rapid prototyping, custom fabrication, and cost-effective solutions.

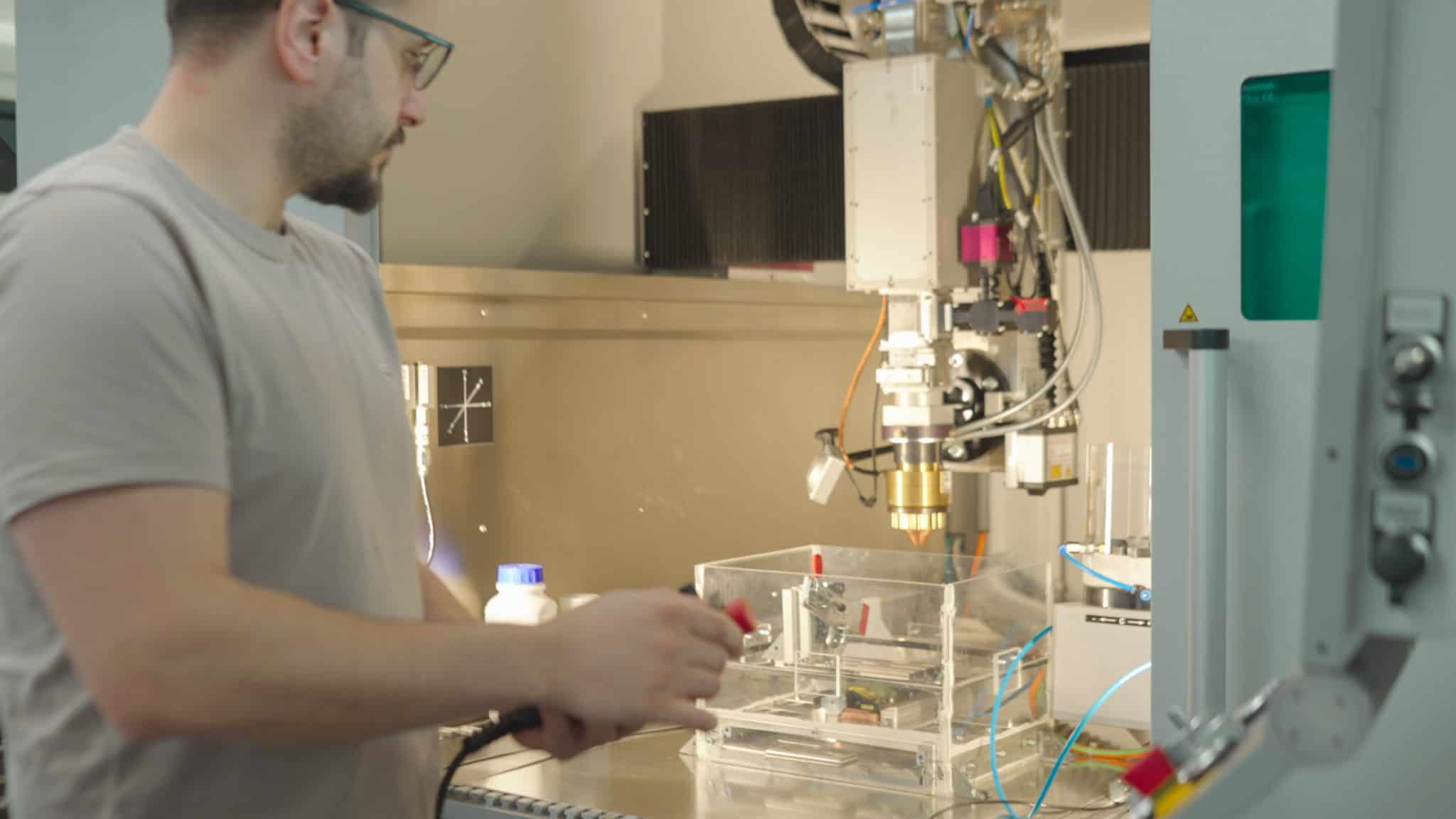

One such breakthrough example comes from Laser Zentrum Hannover e.V. (LZH), a leading research center in Germany specializing in laser technology. The Optical Components Department at LZH, led by Research Associate Joshua McCauley, faced a unique challenge in their optical experiments. Traditional aluminum chambers used in laser experiments posed issues with airflow, thermal instability, and high production costs.

How BigRep 3D Printing Transformed Laser Research at LZH

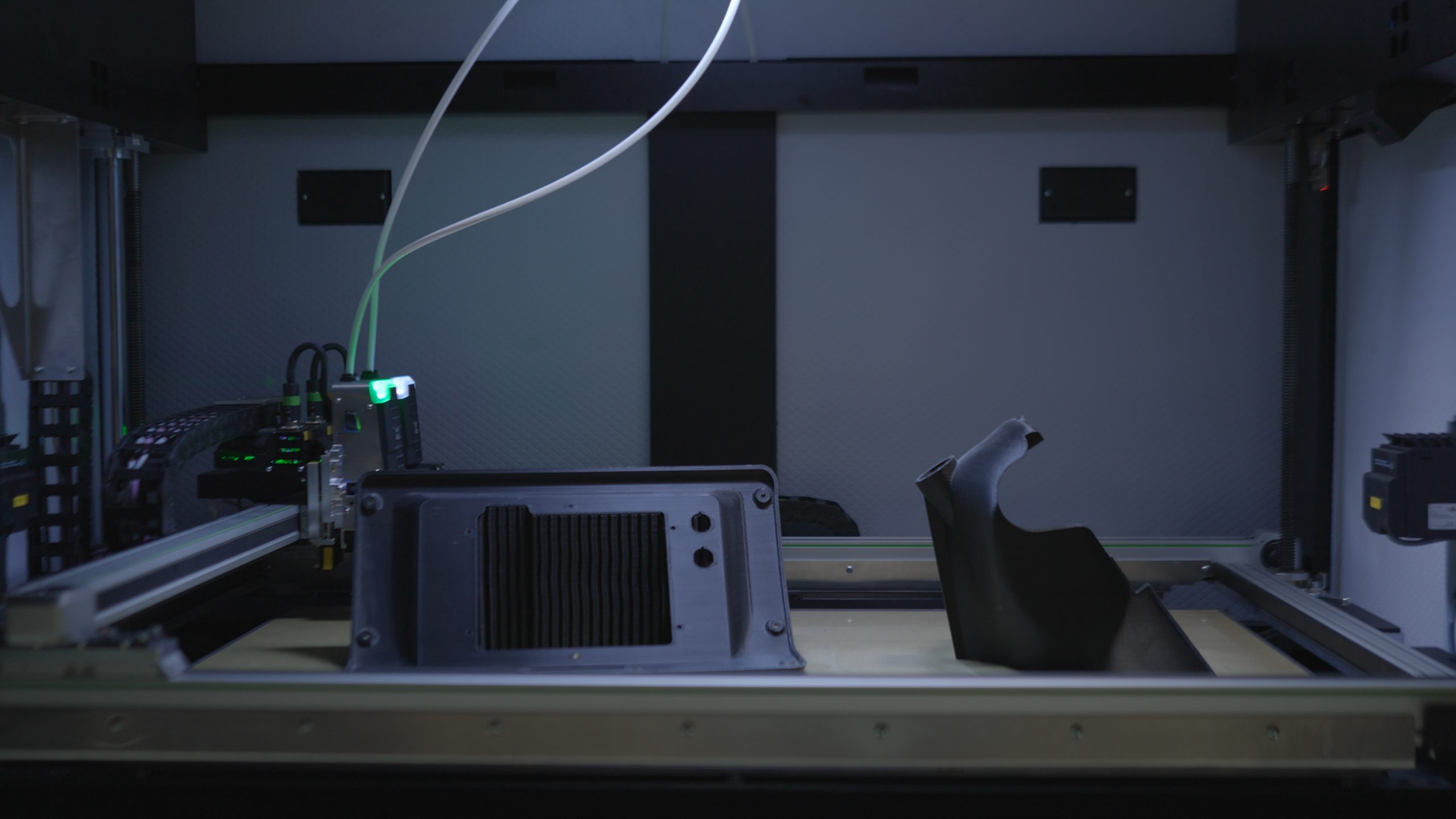

To address these challenges, the team at LZH turned to BigRep’s VIIO 250, a large-scale 3D printer that enabled them to create custom experiment environments tailored to their needs. The results were remarkable:

Design Flexibility

Traditional manufacturing methods limited customization, but with BigRep’s capabilities, LZH could print complex, modular chambers with swappable components.

Scalability

With BigRep VIIO’s massive build volume (1000 mm x 500 mm x 500 mm), LZH could print full chamber structures rather than being restricted to smaller components.

Print Engineering-grade Materials

The dual-wall chamber design provided better control over temperature fluctuations, significantly improving results and reliability.

Cost Efficiency

Instead of costly outsourcing, the research team could manufacture their chambers on-site, drastically reducing expenses while expediting experimentation.

Empowering Universities with Additive Manufacturing

The benefits of 3D printing extend beyond high-level research. Universities and educational institutions worldwide are adopting additive manufacturing for:

- Rapid Iteration and Experimentation – Quickly prototype and refine ideas without the constraints of traditional fabrication.

- Unleashing Creativity – Students and researchers can explore innovative designs that were previously impossible to produce.

- Hands-on Learning – Practical applications of 3D printing prepare students for careers in engineering, design, and manufacturing.

Seamless BigRep 3D Printer Acquisition with NeoMetrix

If your institution is looking to enhance its research and development capabilities, NeoMetrix makes acquiring your next BigRep 3D printer and service plan seamless. Our team provides expert guidance on selecting the right system, financing options, and ongoing support to ensure maximum efficiency and performance.

Ready to upgrade your research and education capabilities? Contact NeoMetrix today to explore the possibilities of large-scale 3D printing. – Connect with NeoMetrix!