3D Scanning and Metrology in Non-Industrial Application

3D scanning and metrology—among the myriad of measurement methods out there—are sometimes depicted as being part of state-of-the-art sectors and technologies, accessible only to a handful of initiated masters. But fear not, the democratization of technological advancements makes way for a new era. And so, did you know that nowadays, 3D scanning instruments and their related software suites are not only used in high-end industries, but also in general sectors and niche markets, for the benefit of users, consumers and workers?

This article covers a few contexts and applications of which you would not, at first glance, think as areas of interest for metrology, 3D scanning, 3D printing and reverse engineering. This includes drag racing, museology/archeology, veterinary anatomy and mountain bike. What do these contrasting sectors have in common? At some point, they relied on 3D scanning to meet with their goals in a more efficient manner.

Can 3D Scanners and Photogrammetry Solve the Processing Issue of Outsized Objects?

Since 2017, London’s Natural History Museum is home to Hope, a skeleton of the largest living mammal, the blue whale. The Museum’s core research laboratories were keen to conduct 3D scans on various skeleton components of the whale, particularly its immense skull. The latter, measuring around six meters in length, undoubtedly displayed limitations in terms of handling and movement. Even though the Museum’s research laboratories’ staff had already purchased 3D scanners for items ideally placed on worktables and other solid surfaces, this time would be a whole lot different.

A few elements and instructions were provided by the staff prior to the scanning process:

- The skeleton would most likely be moved during the process

- The timetable for the process has to be fairly short due to getting Hope ready for display

- The engineers must not apply any type of coating to the skull or substructure

With that in mind, along with the laboratories’ staff, Measurement Solutions, one of Creaform partners in UK and leading supplier of 3D measurement and scanning services , presented a 3-step action plan consisting of 1) preparing the environment with photogrammetry, 2) scanning and acquiring data in an accurate manner, and 3) processing the data via real-time visualization.

First, the engineers laid out small reflective surfaces on and around the skull. The engineers relied on the MaxSHOT 3D, an optical coordinate measuring/photogrammetry system ideal for large-scale projects such as Hope. Working with the MaxSHOT 3D means processing objects measuring from 2 to 10 meters, with an accuracy of 0,015 mm/m. The engineers took digital photographic images to compute the locations of each target and thus came up with a permanent reference frame. And so, since the skeleton is susceptible to movement for it is suspended by wires, dynamic referencing (i.e., dynamic tracking) was of utmost importance.

Then, using Creaform’s MetraSCAN 3D scanner and C-Track, the Measurement Solutions Team provided a quick, simple, completely hand-held and accurate scan of the skull. Provided it sees a few targets in its field of view, the 3D scanner can acquire data, all the while being “tracked” in space by the C-Track, which, in turn, can be moved around in the work area to cover even more surface.

Finally, using Creaform’s VXelements software, the engineers could benefit from a real-time view of the 3D scan to detect less detailed spots, missing areas and scope for improvement. To the great delight of London’s Natural History Museum scientists, the whole process was completed in less than two days, and Measurement Solutions’ engineers provided them with several optimized scan data files for future research and accurate anatomical representations to work from.

Is There an Applicability Limit for 3D Scanning Systems?

This case is definitely a stretch. Or is it? Why not scan the limbs of an animal suffering from laminitis and print a device to strengthen the legs, reduce the pain and facilitate rehabilitation?

Holly is a female riding pony from Australia. She suffers from laminitis, a condition that affects the attachment between the hoof and bone, resulting from the disruption of blood flow to the sensitive and insensitive laminae. Depending on how the disease develops, pressure points can be found on the hoof, causing pain and inflammation. The Commonwealth Scientific and Industrial Research Organization (CSIRO) conducted a veterinary clinical research to assess the validity of a 3D-printed horseshoe. In the wake of such research, the Goodwood Racecourse team was curious as to know if the technology could apply to horseracing in the future.

Using Creaform’s HandySCAN 3D scanner ( a legacy product sold by D2M Solutions FZE in Middle East), the CSIRO personnel laid out positioning targets on Holly’s hoof to capture the pressure points and get a digital image of the leg. From there, they manufactured—via 3D printing—the perfect shoe for Holly. To a certain extent, the horseshoe acts as an orthosis to rehabilitate the pony and allow it to gallop again soon after.

Similarly to the case of Holly, several horses from the Mike de Kock Racing stables from Netherlands

benefit from 3D-printed moulds and polymers (EquiMold) manufactured by FormaHoof to correct foot asymmetry and toe/heel irregularities, and to relieve pain. The moulds result from the 3D scanning of horse hoofs using positioning targets, displaying with great accuracy the asymmetry between legs and local lamina irregularities. In a large-scale perspective, the implementation of these technologies revolutionizes the racing and breeding industries, allowing for further improvements to horse performance. As Mike de Kock puts it, horse stables can be somewhat compared to F1 stables.

3D Scanning and Printing Continues Their Expansion in Medical Research

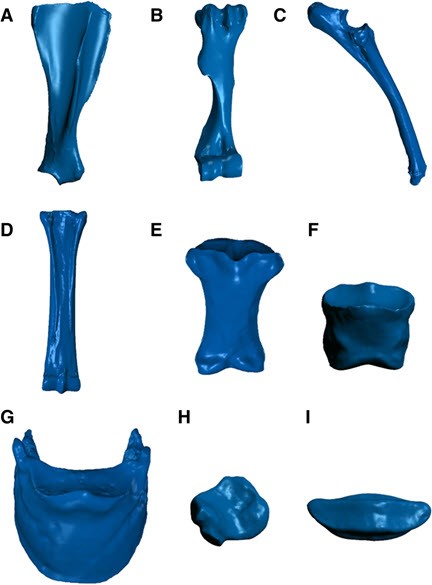

Veterinary medicine education institutions struggle with providing students with real-life, hands-on, anatomical specimens or body parts to conduct research and consolidate theoretical aspects. A research team from the University of São Paulo, writing in the journal 3D Printing in Medicine, noted the high cost of cadaver preservation and acquisition of adequate equipment.

Using a white-light portable 3D scanner from Creaform and a Mojo 3D printer, the researchers were able to scan and reproduce the limb of an adult horse with remarkable accuracy.

The Source: https://www.creaform3d.com/blog/explore-the-uncommon-possibilities-that-portable-3d-measurements-technologies-open-up-part-1/

Professional grade 3D scanning solutions for metrology & engineering applications.