The 3D scanning industry in 2024 has seen remarkable advancements, driven by innovation and fierce competition. As the market evolves, NeoMetrix remains steadfast in delivering unparalleled value to our customers, staying ahead of the curve with cutting-edge technologies. Among the most significant developments this year are the game-changing innovations introduced by Creaform. Let’s explore these advancements and how they revolutionize 3D scanning for industrial applications.

Precision Redefined: HandySCAN 3D|MAX Series

Creaform has once again demonstrated its commitment to excellence with the HandySCAN 3D|MAX Series. Designed specifically for corrosion inspection on large industrial components, this groundbreaking scanner has made waves globally, especially in industries reliant on the integrity of storage tanks and pressure vessels.

With the HandySCAN 3D|MAX, businesses can:

- Achieve unparalleled accuracy and performance in detecting corrosion damage.

- Conduct on-site inspections efficiently, reducing downtime and ensuring operational safety.

- Enhance decision-making processes with immediate, actionable data.

This innovation underscores Creaform’s ability to address critical industry challenges, making it an indispensable tool for REVERSE ENGINEERING and COMPUTER-AIDED INSPECTION solutions.

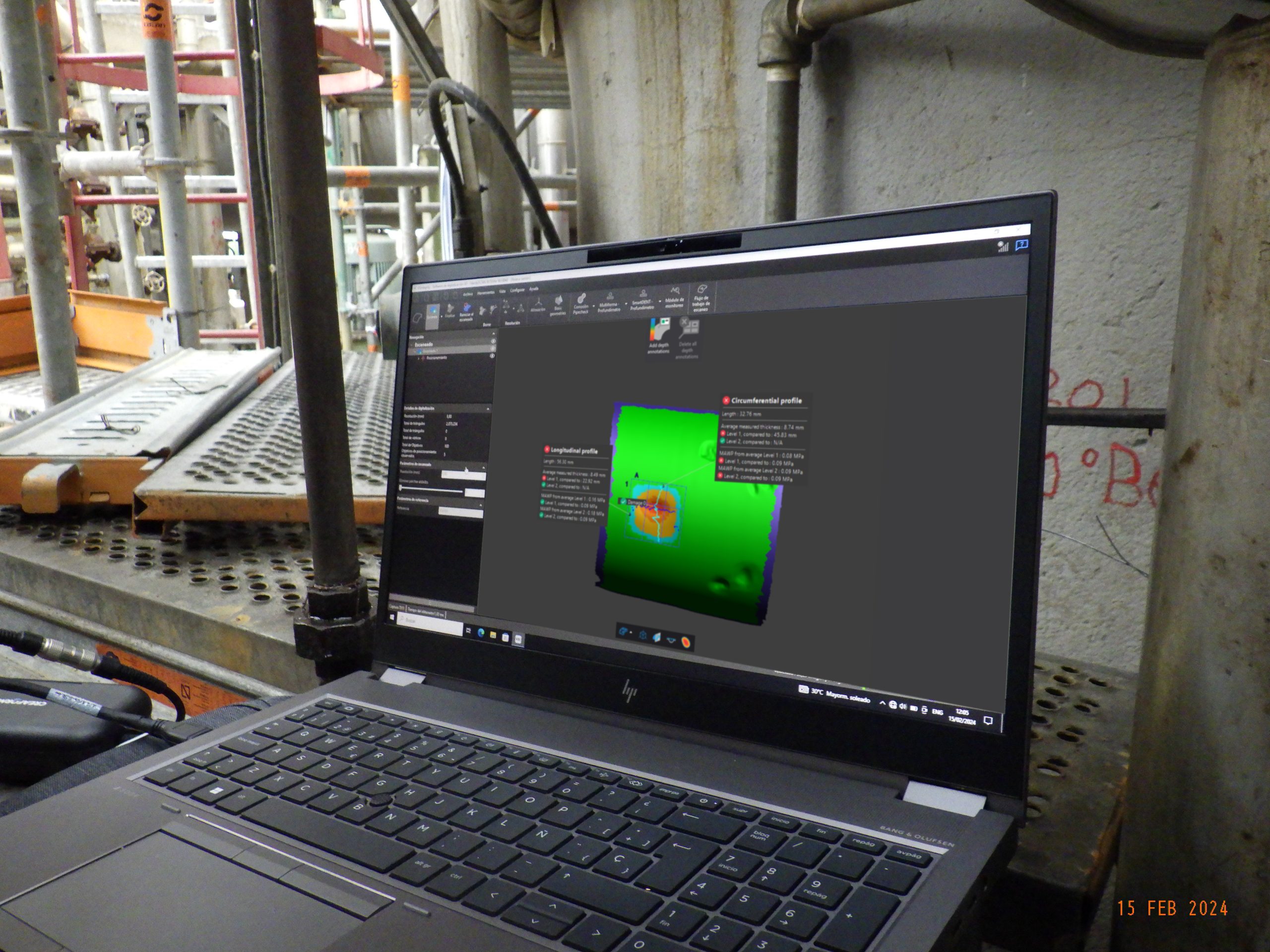

VXintegrity 3.0: A New Benchmark in Corrosion Damage Assessment

The launch of VXintegrity 3.0 has solidified Creaform’s position as a leader in 3D technology-based integrity solutions. By integrating API 579 standard integrity calculations, VXintegrity enables precise on-site assessment of corrosion damage, allowing operators to:

-

Determine necessary actions in real-time, significantly reducing asset downtime.

-

Expedite the restoration of equipment to operational conditions.

-

Improve the reliability of their infrastructure with streamlined evaluation processes.

This integration eliminates the traditional delays associated with data analysis, offering a transformative solution for industries managing critical assets.

Revolutionizing Burst Pressure Evaluations with Scan-to-FEA

Creaform’s Scan-to-FEA solution has redefined the process of conducting burst pressure evaluations. By simplifying Level III analysis, this innovative approach provides:

-

A more efficient alternative to conservative Level II analyses, saving pipeline operators substantial costs.

-

Results delivered in a fraction of the time compared to traditional assessment practices.

-

Synergistic collaboration between Creaform Techno and Creaform Engineering, creating unmatched value for customers.

Moreover, the introduction of a pay-per-use business model opens new revenue streams and market segments, ensuring that this solution continues to drive growth and application development.

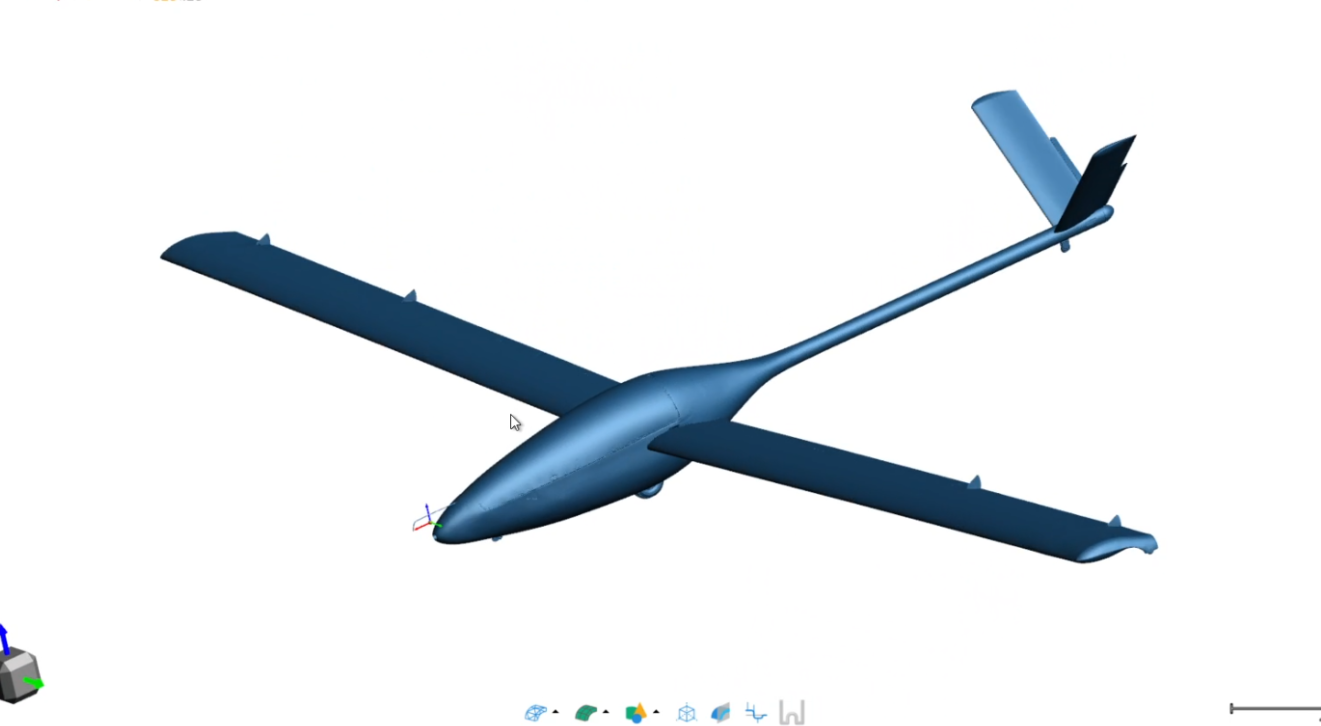

Expanding Horizons: Beyond Automotive and Aerospace

While Creaform’s technologies have long been recognized for their excellence in the automotive and aerospace sectors, their applications are now expanding into unique and specialized industries. From infrastructure to energy and beyond, Creaform’s 3D measurement solutions are addressing critical challenges with precision and reliability.

Your 3D Problems…SOLVED!

Fill out a quick contact form today and let’s explore how our next-gen solutions can help solve your 3D challenges