The Metal 3D Printing Material You’ve Been Waiting For Is Here — And NeoMetrix Is Ready to Deliver

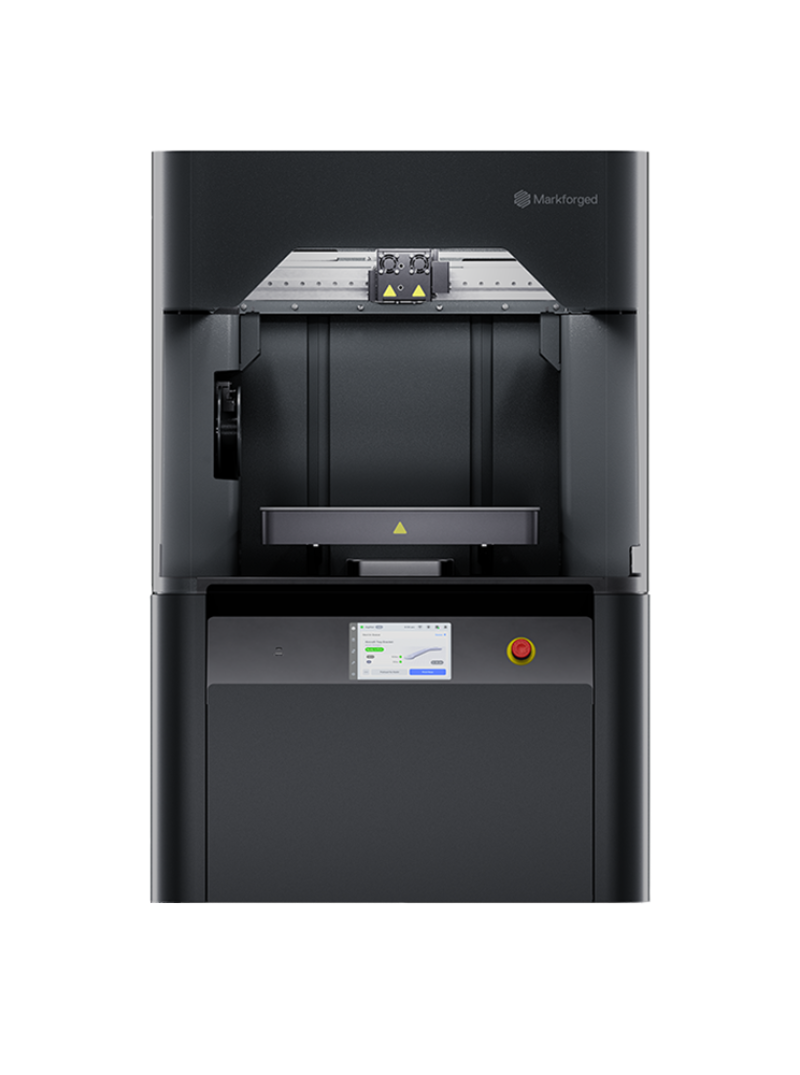

Across industries, the demand for 316L stainless steel in additive manufacturing has been loud and clear—and now, it’s finally a reality. NeoMetrix Technologies, a premier partner and authorized reseller of Markforged, is proud to offer metal 3D printing solutions powered by the FX10, including the long-anticipated launch of 316L stainless steel.

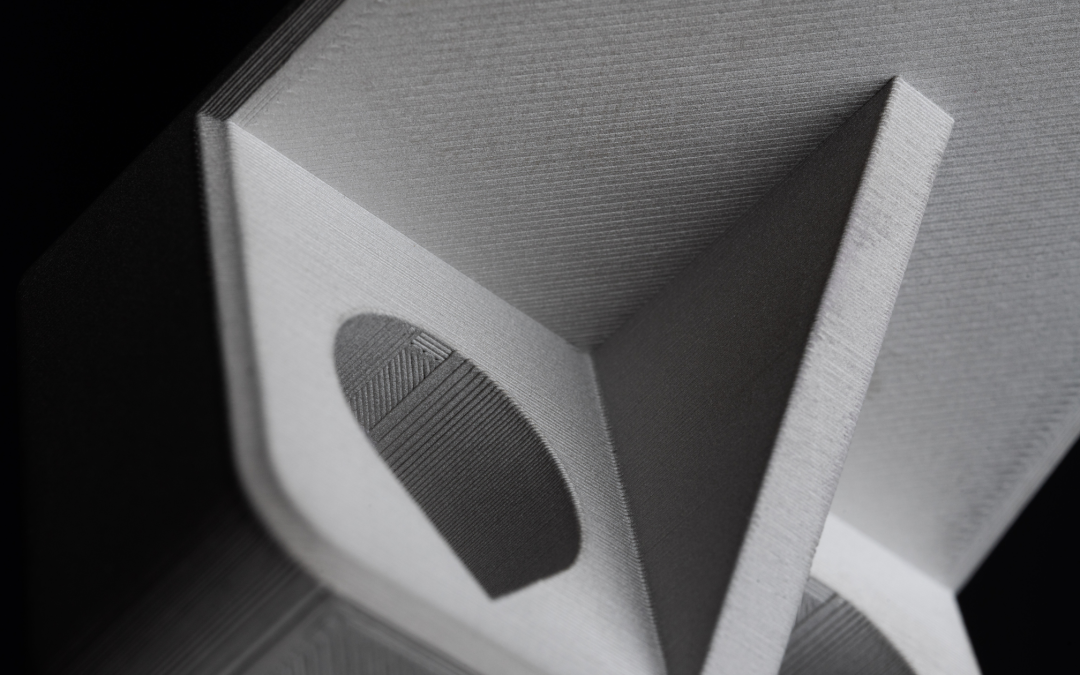

This isn’t just a material update. It’s a major leap in what you can manufacture—strong, corrosion-resistant metal parts that thrive in the world’s harshest environments.

Why 316L? Why Now?

Engineers and manufacturers have been asking for 316L for years—and with good reason. This metal is known for its:

-

Exceptional corrosion resistance

-

Reliability in high-temperature and oxidizing environments

-

Strength and stability in marine, medical, and chemical processing applications

Now available on the Markforged FX10, 316L stainless steel opens up opportunities in food & beverage, automotive, chemical/petrochemical, and industrial tooling.

Real Results, Real Reliability

Markforged didn’t just add 316L—they put it through the wringer. Across 8 FX10 systems, the material was tested for over 5,500 print hours and more than 21,000ccs of material, achieving print success rates well above target benchmarks. That means you and your team can rely on consistent performance right out of the box.

At NeoMetrix, we back that reliability with real-world experience—helping customers integrate metal 3D printing into production environments with confidence.

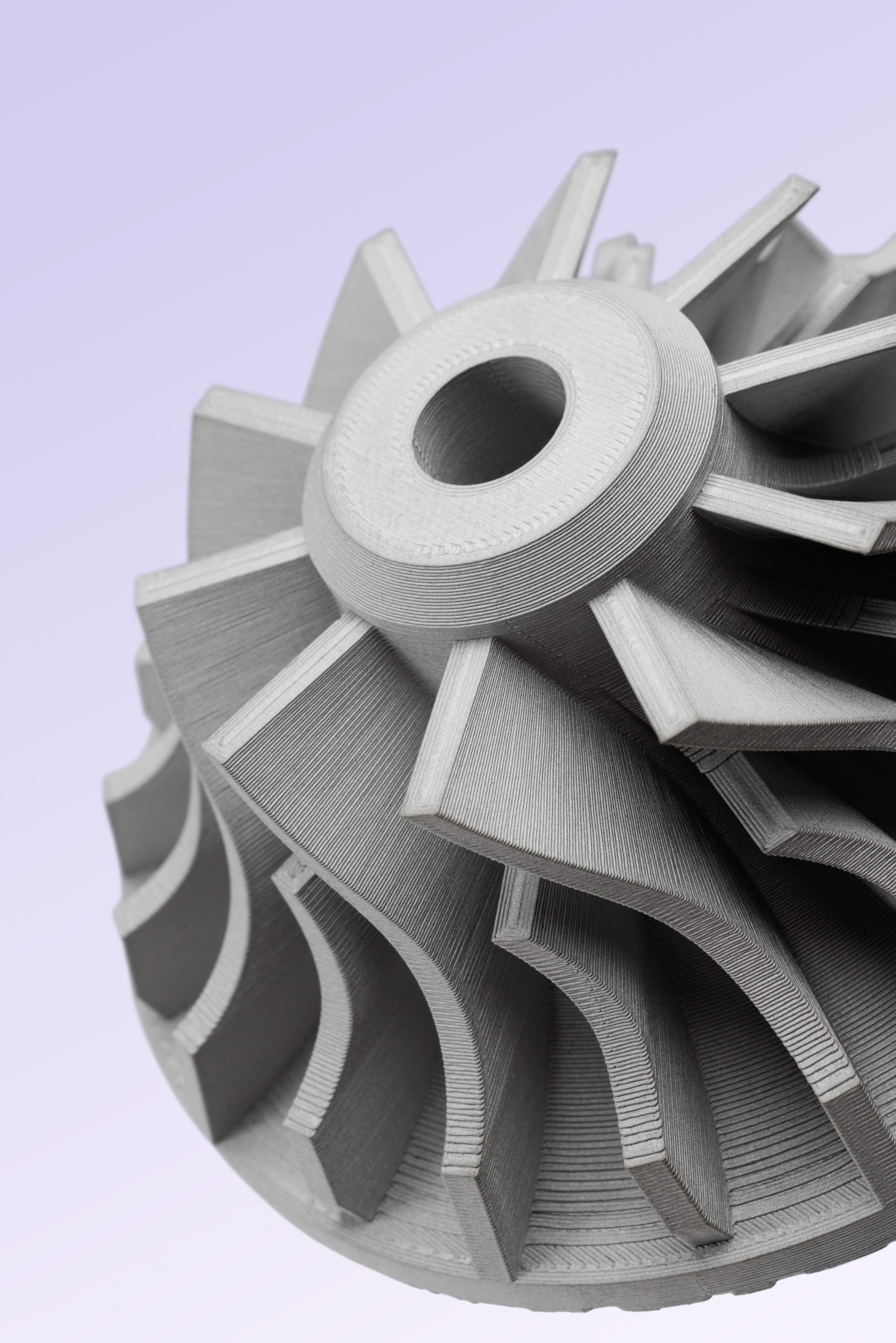

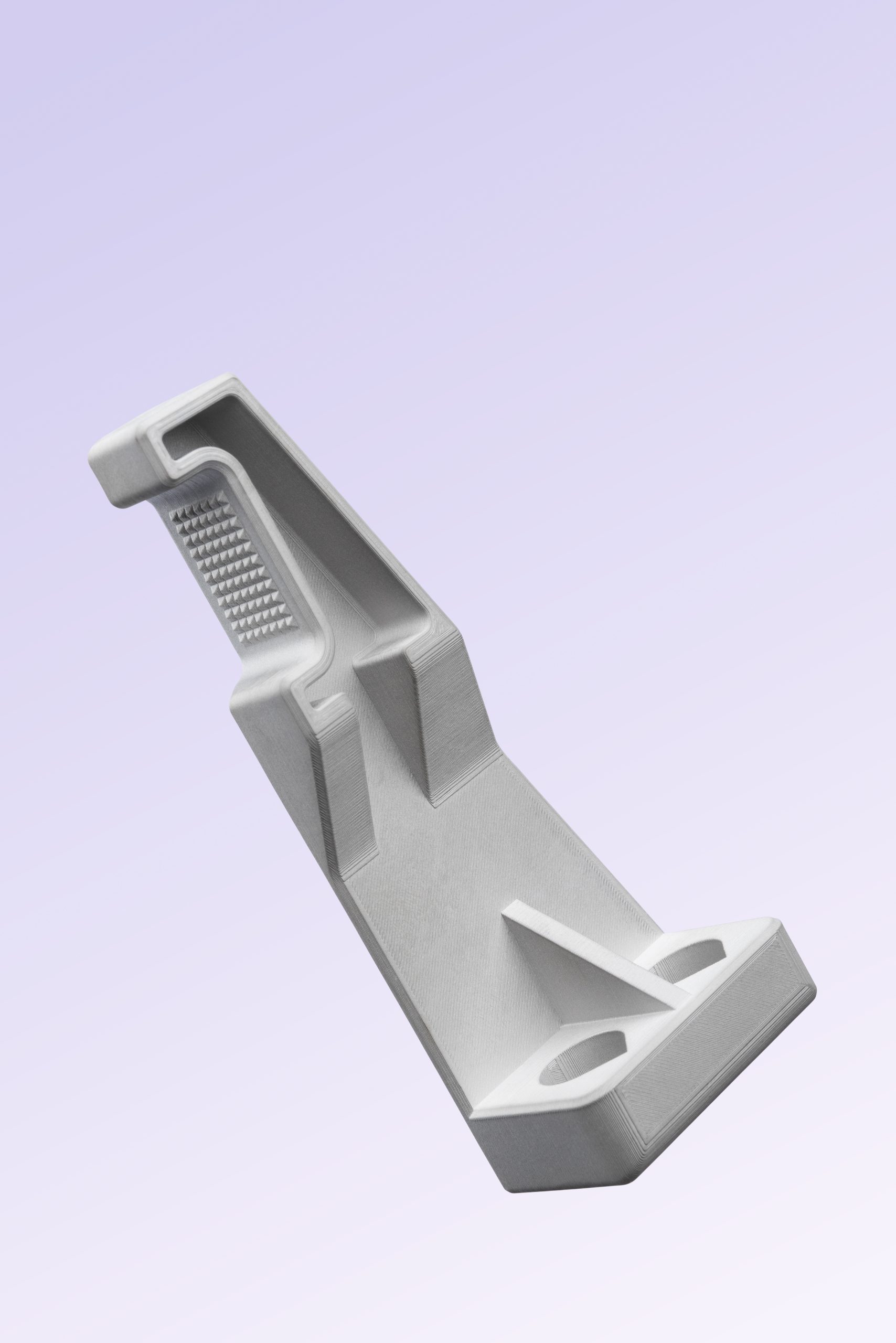

With the power of 316L, the FX10 isn’t just for prototypes. It becomes your solution for:

✅ Functional prototypes

✅ End-use production parts

✅ High-strength tooling

✅ Replacement components built for extreme environments

Whether you’re replacing machined metal parts, building corrosion-resistant assemblies, or looking to slash lead times—the FX10 with 316L delivers industrial results without the traditional costs.

Expand What’s Possible with Metal 3D Printing

As a trusted Markforged partner, NeoMetrix Technologies provides more than just the machine. We offer training, support, and application guidance to get your team up and running fast—so you can capitalize on this breakthrough material from day one.

📞 Ready to talk strategy?

📦 Want a sample part?

💻 Need a live demo?

Let’s get metal.

Important Information

Maximum Print Time

While printing 316L Stainless Steel parts on the FX10, total print time should be under 4 days (96 hours) to prevent thermal debinding on the print bed which can lead to part cracking and warp. Total time on the print bed includes active printing time as well as any time the print is paused.

Wash Mass Loss

When washing 316L Stainless Steel parts in the Wash-1, parts must reach a 3.5% mass loss to ensure enough wax binder is removed before sintering. Not reaching the proper mass loss during the wash process may cause parts to crack during sintering and will allow wax to built up in the furnace exhaust which will lead to clogs.

Review the Understanding the Wash Process support article for more information.

Sintering Gas Usage

Review gas usage information for 316L Stainless Steel sintering runs in the Gas Use Management support article to ensure you have enough gas before starting a run.

Sintering Mass Limit

316L Stainless Steel sintering runs should only be performed with a total run weight of 500 grams or less. Total run weight refers to the fully washed and dried brown part mass.

If you sinter more than 500g of 316L Stainless Steel brown parts in the furnace, the final parts may not be consistent with the 316L chemistry.

Raft Removal

Sintered 316L Stainless Steel parts can tarnish when struck with a hammer during raft removal. It is recommended to peel the raft away from the sintered part with pliers rather than striking the part or raft with force.

Design Considerations

Refer to the Best Practices for Designing 316L Stainless Steel Parts support article for recommendations and important information about designing and slicing parts for 316L Stainless Steel. This support article calls out important information on how to design parts that meet the carbon content requirements of 316L Stainless Steel.