No matter what stage of development your products are in—from concept and CAD drawing to prototype, QA, reverse engineering, final product, or mass production—businesses need faster, smarter solutions to stay competitive.

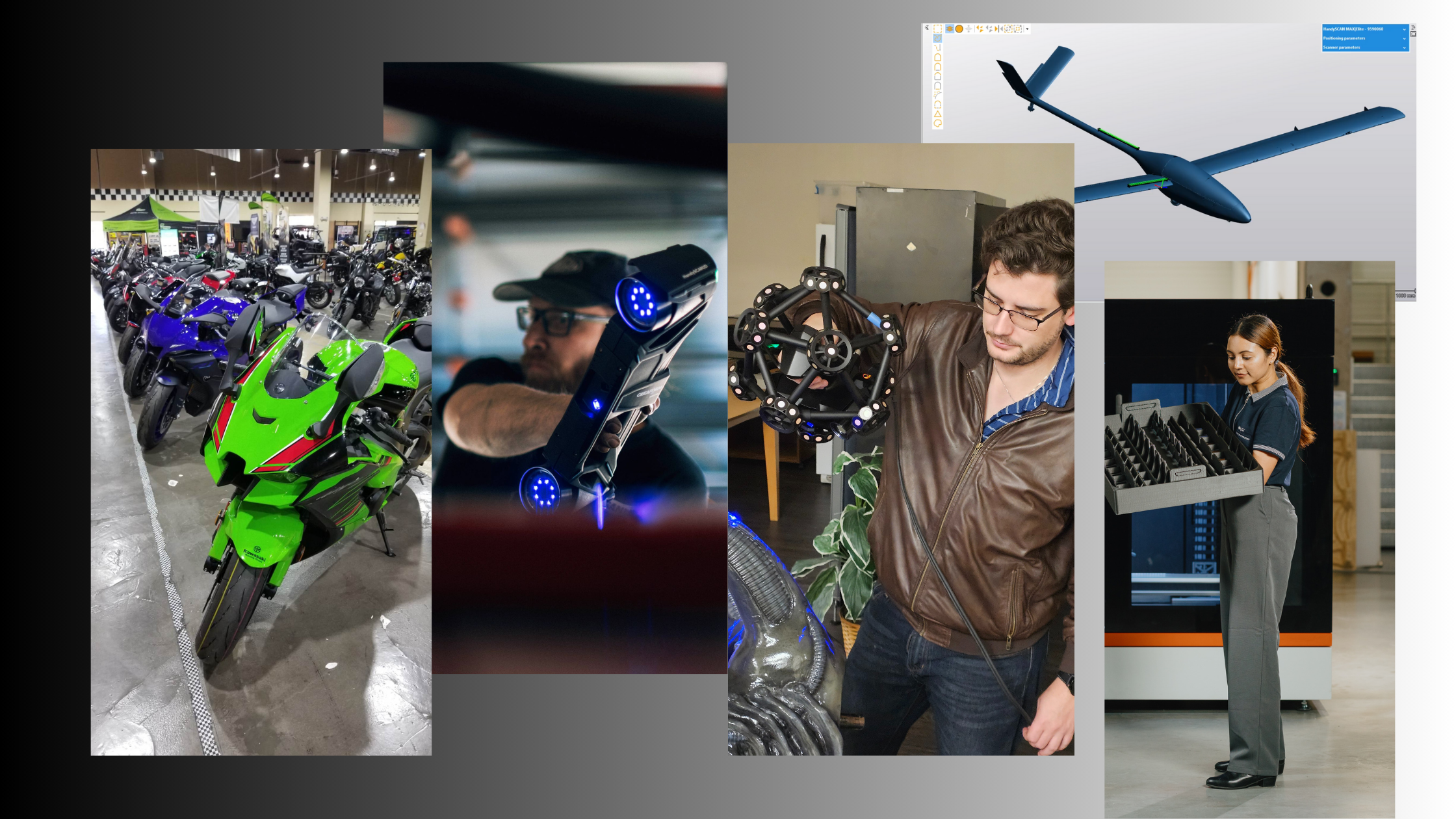

NeoMetrix Technologies offers advanced 3D printing for prototyping, industrial 3D scanning for quality assurance, and reverse engineering services that accelerate every stage of the product development lifecycle. By integrating 3D scanning for accurate measurements, additive manufacturing for rapid prototyping, and outsourced 3D printing services, companies can reduce costs, eliminate bottlenecks, and optimize production from early design to full-scale manufacturing. Our next-gen product development solutions are essential for industries like aerospace, automotive, marine, and engineering overall, giving businesses the ability to innovate faster, improve part accuracy, and bring products to market with confidence.

Let’s break down the key stages of product development and explore how leveraging modern technology can transform your workflow.

1. Idea & Concept

Stage: Brainstorming solutions, defining needs, and sketching out the first vision.

Challenge: Ideas need validation before heavy investments.

How NeoMetrix Helps:

- Understand how equipment & services at NeoMetrix can be used to accelerate projects and get 5-star rated results that meet industry standards with a consultation or demo.

-

3D printers can quickly transform early concepts into tangible proof-of-concept models.

-

Eliminate the need for upfront equipment investments while still giving teams a way to hold their ideas in their hands.

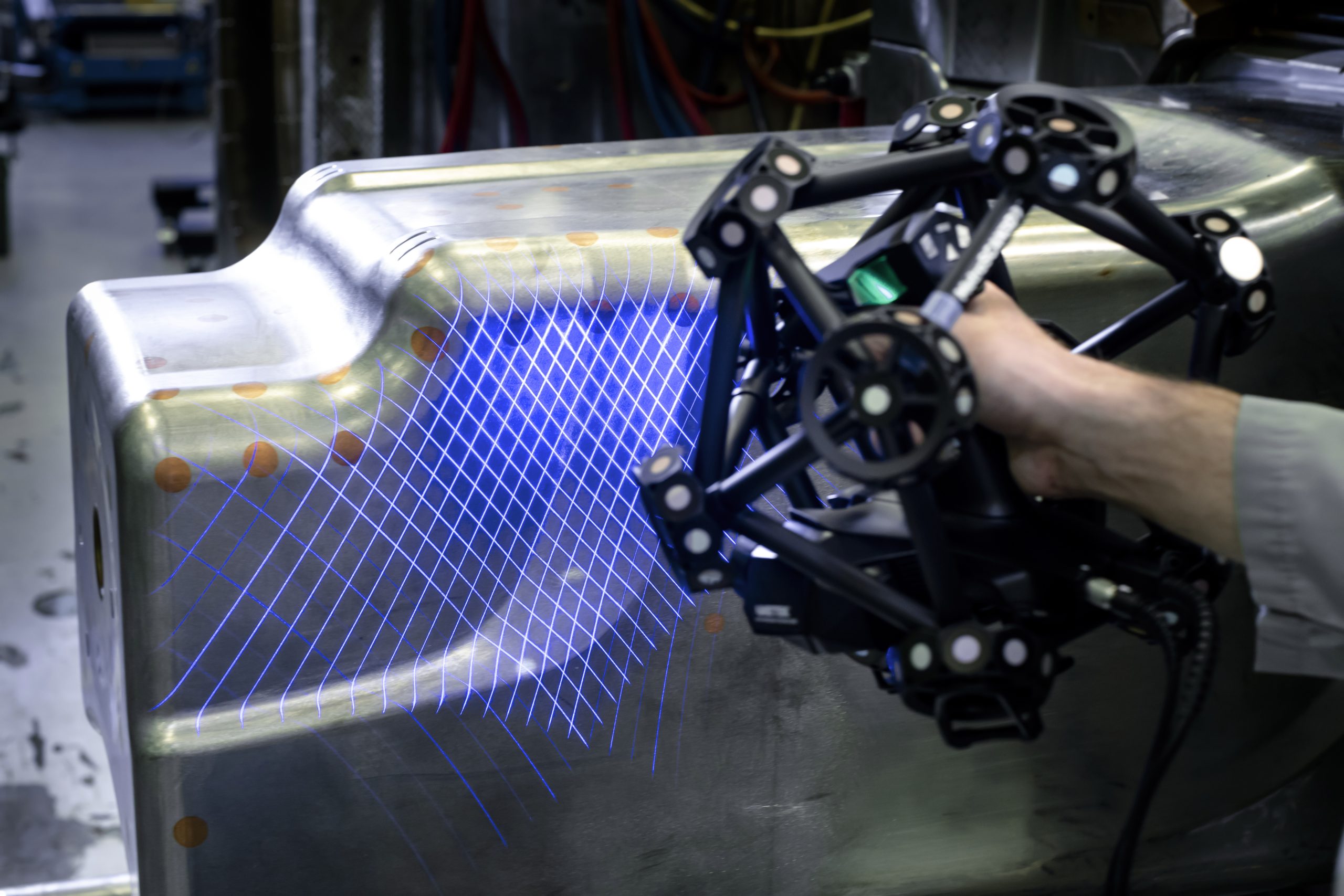

2. Drawing – 3D Scan – CAD Design

Stage: Moving from hand sketches to detailed 2D/3D digital models.

Challenge: Accuracy and design intent must match real-world manufacturability.

How NeoMetrix Helps:

-

3D scanning captures real-world geometries with precision, ensuring your CAD models reflect exact dimensions.

-

Reverse engineering solutions streamline the process of refining existing designs or improving competitor benchmarks.

3. Prototype Development

Stage: Building a functional version to test design, fit, and performance.

Challenge: Traditional prototyping is expensive and time-consuming.

How NeoMetrix Helps:

-

Industrial 3D printing (additive manufacturing) produces prototypes in hours, not weeks.

-

Materials range from durable engineering plastics and high-performance composites, to metal, simulating end-use conditions.

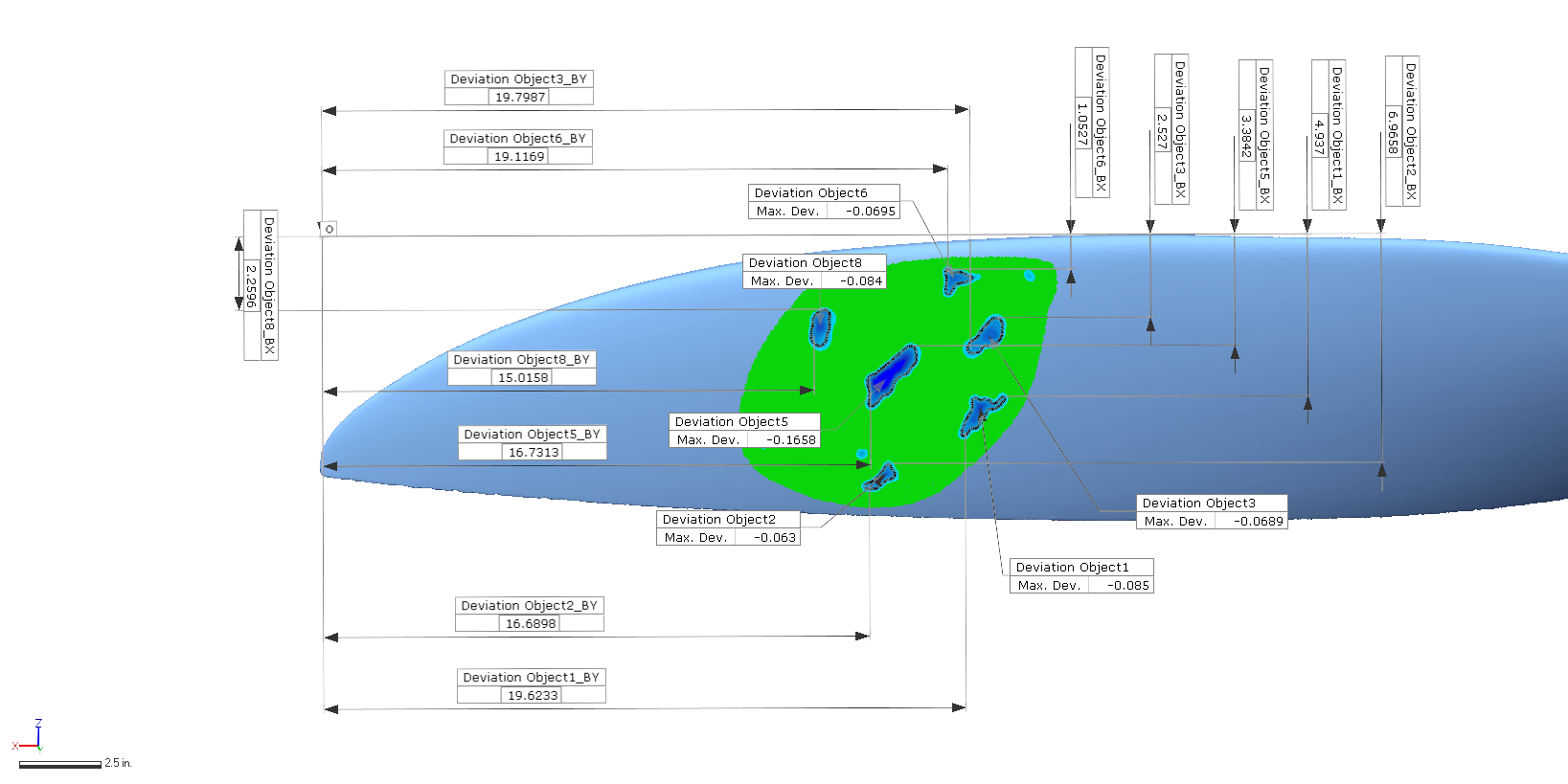

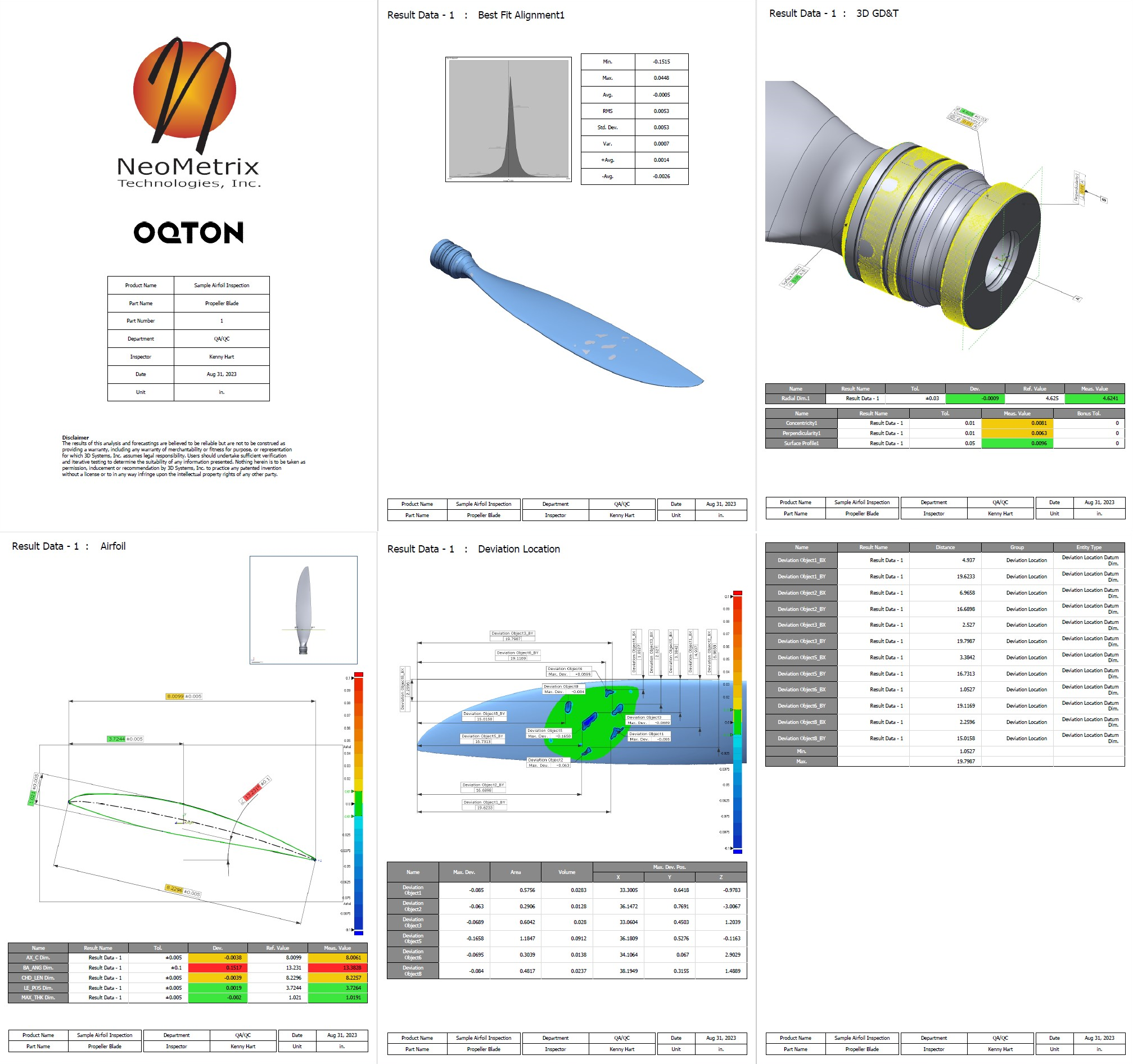

4. Testing & QA (Quality Assurance)

Stage: Verifying function, fit, and durability.

Challenge: Ensuring consistency and identifying flaws before scaling production.

How NeoMetrix Helps:

-

3D scanners perform precise dimensional analysis to detect deviations.

-

Inspection software compares prototypes against CAD models, speeding up validation.

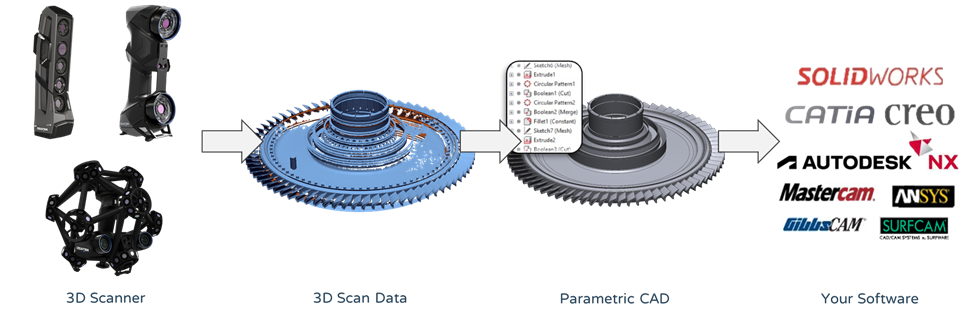

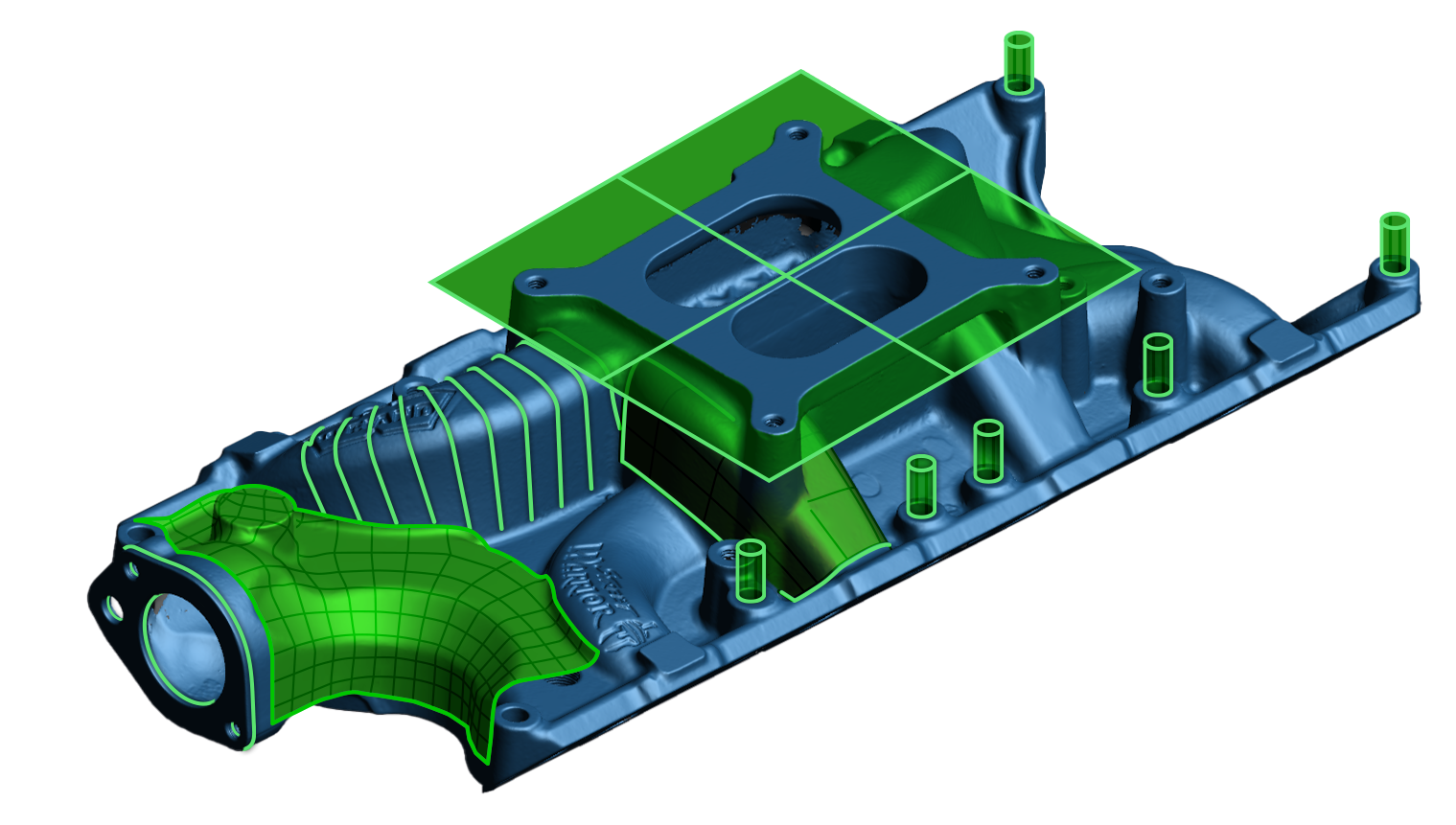

5. Reverse Engineering

Stage: Improving existing parts, repairing damaged components, or replicating designs with no CAD file.

Challenge: Traditional measurement methods can’t capture complex geometries.

How NeoMetrix Helps:

-

High-accuracy scanning converts physical objects into editable 3D CAD models.

-

Enables part redesign, optimization, and even digital archiving of legacy products.

6. Final Product Development

Stage: Preparing for production with optimized designs and tested parts.

Challenge: Balancing innovation with manufacturability.

How NeoMetrix Helps:

-

Additive manufacturing allows low-volume runs and custom parts without tooling costs.

-

NeoMetrix’s engineers ensure your product design is production-ready and cost-efficient.

7. Quality Control

Stage: Maintaining strict standards during and after production.

Challenge: Variability in manufacturing can lead to costly recalls.

How NeoMetrix Helps:

-

Automated scanning systems verify every part against tolerances.

-

Data-driven QA improves customer trust and reduces waste.

8. Production / Manufacturing

Stage: Scaling to meet market demand.

Challenge: Efficiency and repeatability are key to profitability.

How NeoMetrix Helps:

-

Industrial 3D printers deliver on-demand production with no minimum order requirements.

- Access 3D printing your parts in a variety of engineering-grade + high-performance materials.

-

Hybrid strategies (outsourced services + in-house equipment) optimize both speed and cost.

Why 2025 is the Year to Reimagine Your Product Development

With markets moving faster than ever, companies can’t afford lengthy, outdated development cycles. Businesses that adopt 3D scanning, 3D printing, and reverse engineering solutions are not just keeping up—they’re setting the pace.

At NeoMetrix Technologies, we provide both the equipment and the expertise to guide you through every stage of development. Whether you’re refining a concept, scaling production, or reverse-engineering a legacy part, our team helps you shorten timelines, lower costs, and innovate with confidence.

Explore the latest advancements

in design and manufacturing!

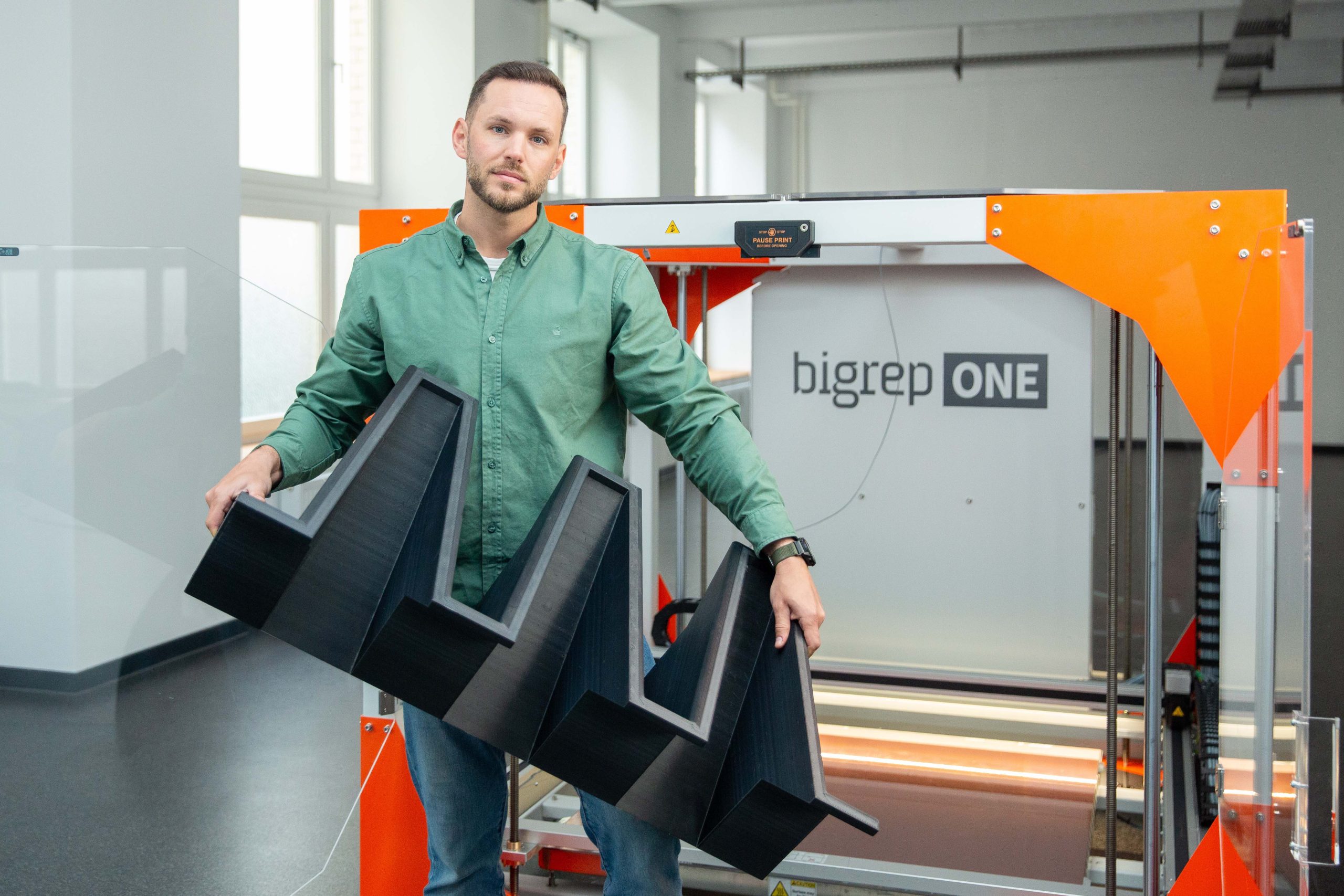

BigRep VIIO 250

HandySCAN Black+ Elite

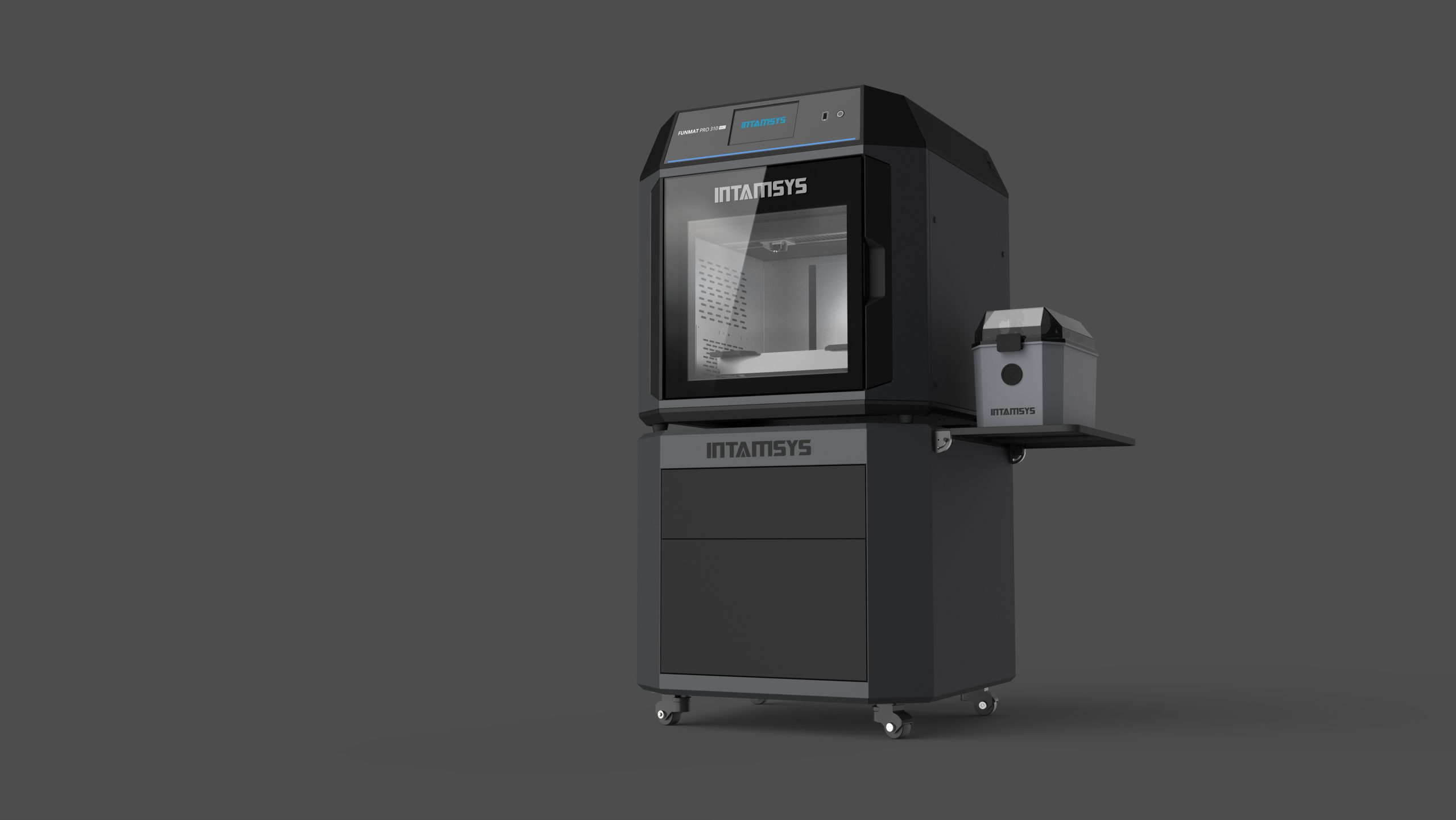

FUNMAT PRO 310 NEO

👉 Are you ready to accelerate your product’s journey from concept to market?

Schedule a consultation with NeoMetrix today!