From Scan to Print: Recreating a Kayak Paddle with 3D Technology

At NeoMetrix, we use next-gen 3D technology to bring real-world objects to life. In this project, we captured a kayak paddle using the Peel 3 scanner, refined the digital model in PeelOS, and brought it to production using the BigRep VIIO large-format 3D printer.

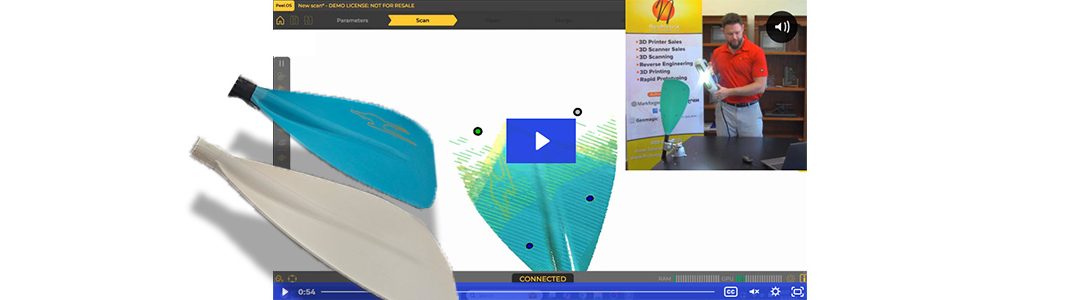

Step 1: High-Precision 3D Scanning

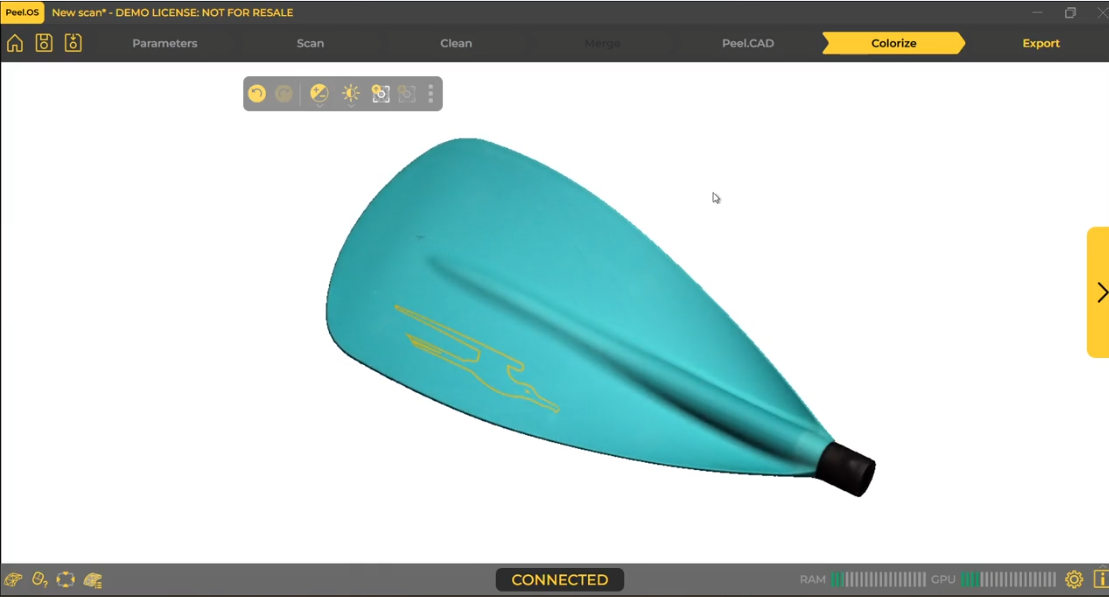

The Peel 3 scanner provided fast, accurate data capture, turning the paddle into a detailed 3D mesh in minutes. PeelOS made it easy to visualize and optimize the scan using tools like Edit Boundary, Smooth Mesh & Detail, and Fill Hole for a clean, watertight model.

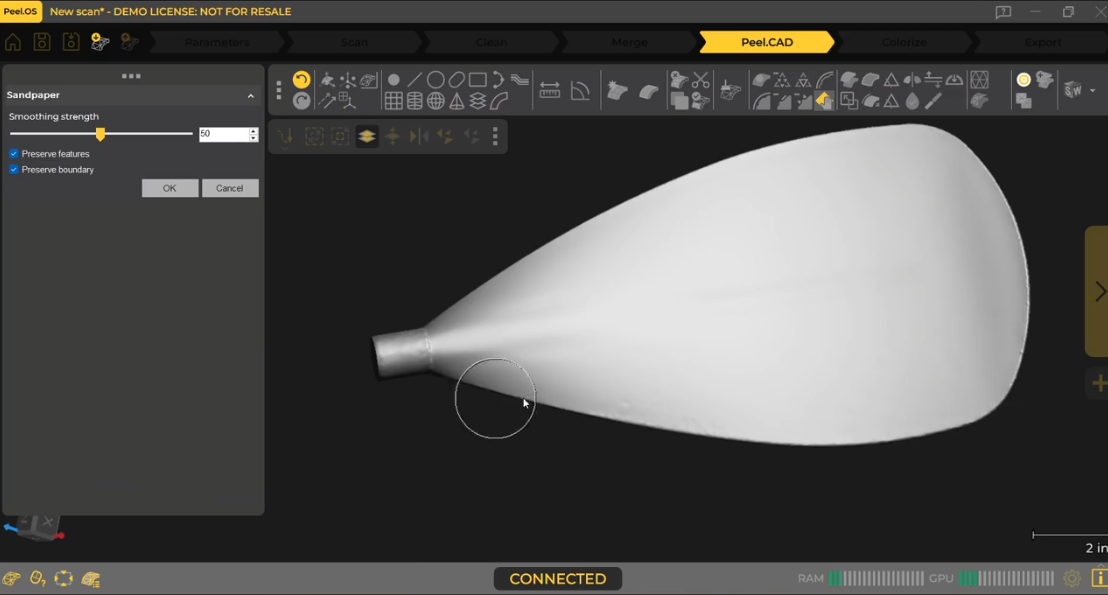

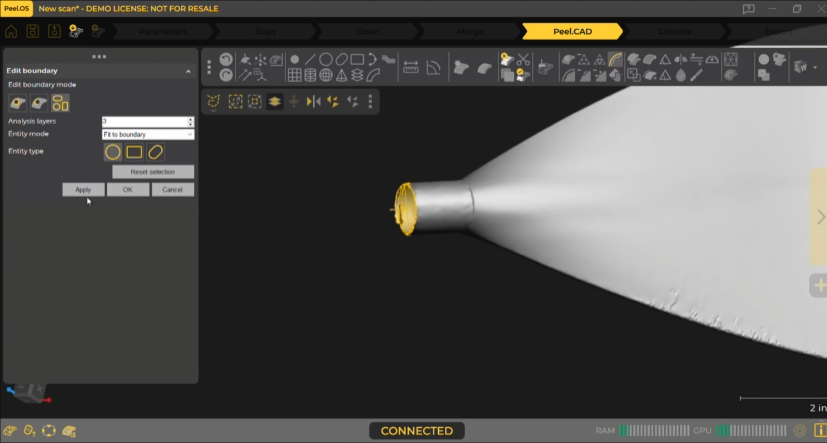

Step 2: Advanced CAD Modeling in Peel.CAD

With the scan complete, we imported the model into Peel.CAD. Here, we could refine the design, add features, and make necessary adjustments for 3D printing. Peel.CAD’s intuitive tools ensure accurate reverse engineering and seamless CAD integration.

Step 3: Large-Scale 3D Printing

Next, we brought the paddle to life using the BigRep VIIO and PRO HT material. Known for its strength and heat resistance, PRO HT is ideal for outdoor and marine applications. The large build volume of the VIIO ensured the paddle could be printed at full scale in one piece.

Print Details:

3D Printer: BigRep VIIO250

Material: ProHT

Print Time: 7 hrs 10 mins

Print Speed: –mm/s

Scan. CAD. Print!

This seamless workflow highlights the power of combining 3D scanning, CAD modeling, and large-format printing for rapid prototyping and reverse engineering. Whether you’re restoring equipment, designing custom parts, or innovating new products, NeoMetrix has the solutions to make it happen.

Ready to see how this technology can work for your business? Contact us today!

Every top modern business deserves access to the transformative capabilities of 3D printing.

Schedule a FREE 3D Printing Discovery Session to see which solutions and equipment are best to suit your design and production challenges. Also be sure to download our BigRep Smart Decision Blueprint.