From aerospace to automotive, healthcare to electronics, the list of applications for these high-performance polymers is as expansive as it is diverse. Complex geometries that once seemed beyond reach are now attainable with precision and efficiency. Functional prototypes, end-use parts, and even production-grade components can be realized with a level of performance that meets or exceeds metal counterparts.

Let’s dive into some of the functional materials and range of capabilities that are revolutionizing our approach to manufacturing.

INTAMSYS’s PEEK (Polyether Ether Ketone)

A game-changer for industries demanding uncompromising performance. With high-temperature resistance and exceptional mechanical properties, PEEK is the go-to material for aerospace, automotive, and medical applications. Its ability to withstand extreme environments and provide superior chemical resistance makes it a standout choice for critical components.

Key Features:

- High-Temperature Resistance: With a glass transition temperature of up to 143°C, PEEK excels in applications where exposure to heat and pressure is commonplace.

- Exceptional Strength-to-Weight Ratio: PEEK’s robust mechanical properties ensure lightweight yet sturdy parts, reducing overall system weight.

- Chemical Resistance: It stands up to a wide range of chemicals, making it ideal for applications in aggressive environments.

ULTEM: Meeting Rigorous Industry Standards

For industries that demand compliance with stringent regulatory requirements, INTAMSYS’s ULTEM (Polyetherimide) material delivers. Known for its flame resistance, low smoke generation, and high dielectric strength, ULTEM is a top choice for aerospace, automotive, and electronic applications. Its ability to maintain structural integrity in demanding conditions sets it apart.

Key Features:

- Flame Resistance: ULTEM exhibits excellent resistance to flames, meeting key safety standards for industries where fire safety is paramount.

- High Dielectric Strength: It’s an ideal choice for electronic components, offering excellent electrical insulation properties.

- Chemical Compatibility: ULTEM is resistant to a wide range of chemicals, ensuring durability in harsh environments.

PPSU: Durability Redefined

INTAMSYS’s PPSU (Polyphenylsulfone) material is engineered for durability and versatility. With exceptional impact strength and resistance to moisture and chemicals, PPSU is a go-to choice for medical, aerospace, and automotive applications. Its ability to maintain structural integrity over a wide range of temperatures makes it invaluable in demanding environments.

Key Features:

- High Impact Strength: PPSU exhibits outstanding toughness, making it suitable for applications where durability is critical.

- Moisture and Chemical Resistance: It stands up to moisture, solvents, and a wide range of chemicals, ensuring long-lasting performance.

- Thermal Stability: PPSU maintains its structural integrity even at elevated temperatures, making it a reliable choice for high-temperature applications.

With INTAMSYS’s exceptional range of materials, we’re not just printing parts; we’re shaping the future of manufacturing.

Explore our extensive portfolio of INTAMSYS printers and materials and discover how you can expand your capabilities additive manufacturing.

This blog was originally shared on intamsys.com. You can read more here!

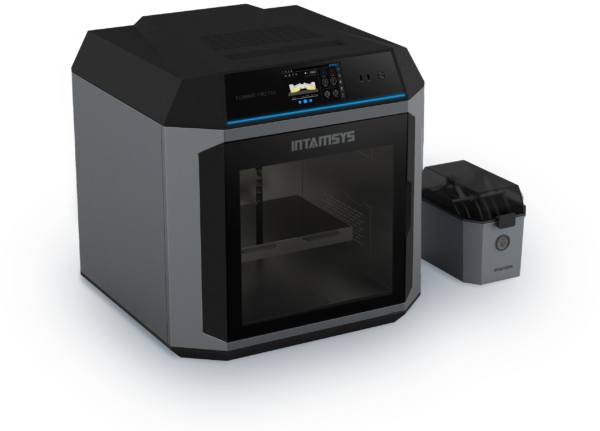

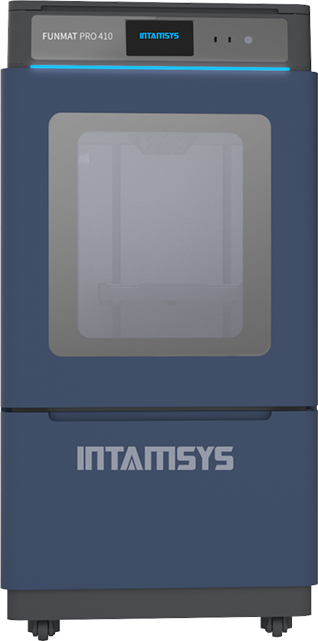

FUNMAT PRO 610HT