As the demand for electric vehicles (EVs) continues to surge, the need for innovative, efficient, and high-quality manufacturing processes has never been more critical. This blog focuses the challenges faced by manufacturers in producing the next generation of EV battery enclosures, which are essential to vehicle safety, performance, and efficiency.

EV enclosures are often integrated into the vehicle’s chassis and are crucial for protecting battery modules and their electrical and thermal management systems. Made from lightweight materials to extend vehicle range and reduce energy consumption, these structures must be manufactured with the highest precision to ensure they meet stringent industry standards.

Get 3D Scanning Equipment for Your Business or Projects!

Addressing Manufacturing Bottlenecks with Advanced Metrology

Traditional methods like Coordinate Measuring Machines (CMMs) have long been the gold standard for quality inspection due to their accuracy. However, many manufacturers face limitations with stationary CMMs. As in the case of DURA Automotive, these limitations include capacity issues and a lack of flexibility, as the CMMs are often overloaded with inspections and can only operate from a fixed location, slowing down the entire production process.

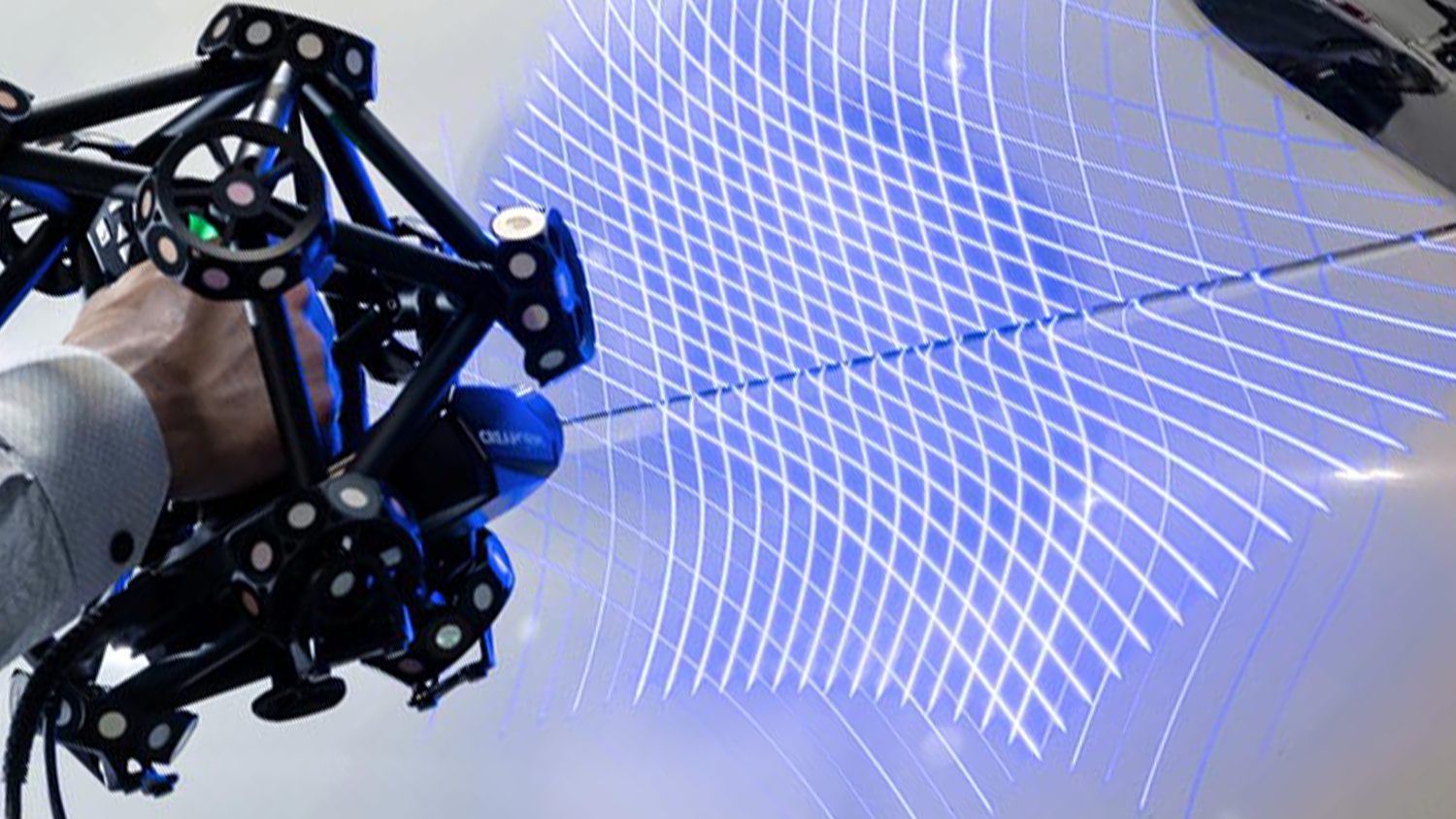

To overcome these challenges, forward-thinking manufacturers are turning to more advanced, portable 3D scanning solutions to enhance flexibility and speed on the shop floor.

Empowering Manufacturers with Mobility and Precision

At NeoMetrix Technologies, we provide next-gen 3D scanning solutions that revolutionize how manufacturers approach quality control. Our featured products, such as the Creaform MetraSCAN Black Elite and Geomagic Design X / Control X software, offer unmatched precision and mobility for on-site measurements.

These portable 3D scanners capture high-accuracy data directly on the shop floor, eliminating the need to transport parts to a metrology lab. With accuracy levels reaching up to 0.025mm (0.0009 in), these scanners can rapidly measure complex geometries and entire structures in a single setup, significantly reducing inspection times and increasing throughput.

By integrating 3D scanning technology into the production process, manufacturers can perform checks on the shop floor, ensuring quality is maintained at every step. This approach not only speeds up production but also enhances overall manufacturing efficiency.

Fuel your design process!

Our team of experts are ready to help!

Accelerate Your Production & Design with Precision

” We use the Creaform MetraSCAN 3D and HandyPROBE as portable measurement stations to measure incoming extrusions and get quick scans of the product before it moves forward to a mill to ensure the mill will accept the part. Thanks to Creaform, we have increased our capacity by 75%.”

-Branden Head, Metrology Supervisor at DURA Automotive

The distinct performance obtained with Creaform and Polyworks in DURA’s production environment has confirmed their strong reputation in the 3D measurement industry. “Creaform and its 3D measurement solutions were pivotal for the measurement capability in our facility,” adds Mr. Head. “Our project would have struggled with capacity and mobility without Creaform’s and Polyworks’s technology.”

The partnership between DURA and Creaform will certainly continue as the global automotive supplier is now exploring the possibility of integrating Creaform technology into its automated manufacturing process. For sure, the metrology team can always count on Creaform’s dedicated training and support to achieve this next goal.

Original Reference Article by Creafrorm: https://www.creaform3d.com/blog/how-3d-scanning-optimizes-the-underbody-aerodynamics-of-race-cars/

Ask us about 3D scanning services and equipment!