In the early 1990s, Franco Bercella’s dream was to build an ultra-light airplane, which is how he began to learn about composite materials. But designing an airplane wasn’t enough, he also wanted to build it. Franco wasn’t easily discouraged by details. He decided that he would simply build the factory where his ultra-light airplane could be made. The company was founded in 1996 with the objective of refining the production of structures used in advanced applications. Currently, the company’s main sectors are automotive, aerospace, defense, and railroads. Through the years and thanks to a continuous research and development program, Bercella has acquired extensive, high-level experience in the production of structures in light composites and alloys for the aerospace, defense, and automotive industries, designing new solutions that are continuously evolving.

The integration of these exclusive productive capacities with an impeccable design service has made it possible for Bercella to become a steady and reliable partner for its customers.

The Lunar Project:

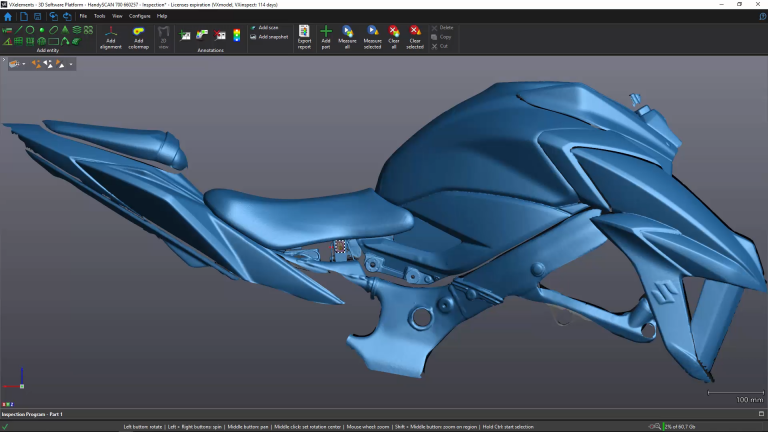

A recent collaboration with Carboni e Metalli – an innovative start-up in the Parma area in Italy- resulted in the creation of the Lunar Project: a motorcycle that combines composite materials produced by Bercella and metallic products produced in additive manufacturing. For example, the fuel tank was made of carbon fiber: a delicate, demanding process, starting from the design, to the conception of a mold, going up to the production of the final component.

Right from the start of the process, each step faced the strictest controls. Bercella adopted a philosophy that could be defined as “the price of quality”: it is more advantageous to invest in quality controls during the production process than lose time and money in re-working the product due to faults or components sent back by the customer.

The model went through high-quality control requirements thanks to the HandySCAN 3D by Creaform. Before being used to laminate the mold, the dimensions were checked and compared with the reference 3D design, by using a fast high-definition scan-to-CAD file. The same process was repeated using the mold, and then once again with the final tank. This workflow, which may seem long and complex, actually saves time. Having the assurance that every step along the production process of a component was taken according to the “price of quality” philosophy makes the work of all involved parties easier.

HandySCAN 3D by Creaform 3D was the best option for rapidly reproducing all the components produced for the Lunar Project. For this reason, the Bercella design team placed total trust in the HandySCAN 3D, considered a fundamental tool for its daily working processes.

Bercella used HandySCAN 3D and VXelements for data acquisition. Not only does HandySCAN 3D offer the best performance in terms of rapid and reliable analysis of components, but it also guarantees fast importing of CAD programs.

The ease in comparing the scanning result and the CAD geometry is a fundamental aspect to consider when selecting the best control method. This feature has been very important for many projects where standard measurement techniques are not suitable or sufficient for ensuring accurate results.

Over recent years, instead of replacing different systems and technologies, Bercella has integrated solutions already available in the company. This resulted in a more dynamic approach: in the case where many systems are not available, there is always a backup solution. Creaform became part of this scenario to reinforce the capacity to satisfy the highest standards on the market, from customers to the company.

Why choose Creaform technology?:

The need for a rapid and precise tool for measuring and controlling small to medium size components led the company to assess a varied range of solutions: among all of these, Creaform turned out to be the most promising technology, thanks to its reliability and simplicity of use.

Specifically, the Lunar Project was composed of parts with complex geometries that required 3D reconstruction to verify dimensions, which otherwise would not be detectable rapidly and economically using standard tools. Bercella’s primary objective is to give customers the tranquility they need. Guaranteeing the quality not only of products but also of all the controls performed, in accordance with the requirements.

Precluding the fact that HandySCAN 3D has differentiated from its competitor’s thanks to its portability and ductility, it is also used by Bercella exclusively in the control room, where parameters like humidity and temperature are kept under constant control. Therefore, in any condition, the components that require scanning are maintained in a controlled environment. This is an internal standard that Bercella established for controlling all components, instruments, masks, and molds. This also applies to production conditions since composites are produced in clean rooms, where the temperature, humidity, and even air particles are controlled.

Creaform technologies for saving time and costs

Saving time is also reflected in delivery times. The possibility to keep components inside the company and not have them transferred to partner companies means more control over production because inspections are performed each time that a component re-enters the facility, requiring time that impacts logistics and systems scheduling.

The use of Creaform technology allows Bercella to increase levels of trust in two important sectors – control and production: defects or problems can be found quickly, so all deriving risks can be mitigated in the best way possible.

Massimo Bercella, the Sales Manager of Bercella explains, “We will definitely collaborate with Creaform in the future. We firmly believe that the results of a partnership are revealed when the Buyer-Seller relationship is taken to the next level. We will always need reliable technology for controlling parts and components, so the support of a partner like Creaform is essential.”