Problem:

Townley Engineering and Manufacturing had aging volute molds that needed to be replaced. They wanted to recreate there molds by cutting them on a CNC machine.

Traditional Method:

To recreate the organic geometry found in the volute you need to use a combination of calipers, a tape measure, and cardboard patterns. This method is inaccurate and can create problems when you have existing parts that need to mate up.

NeoMetrix Solution:

- Scanned in house using the Vivid 9i wide lens (accuracy of .008”) (Figure 1)

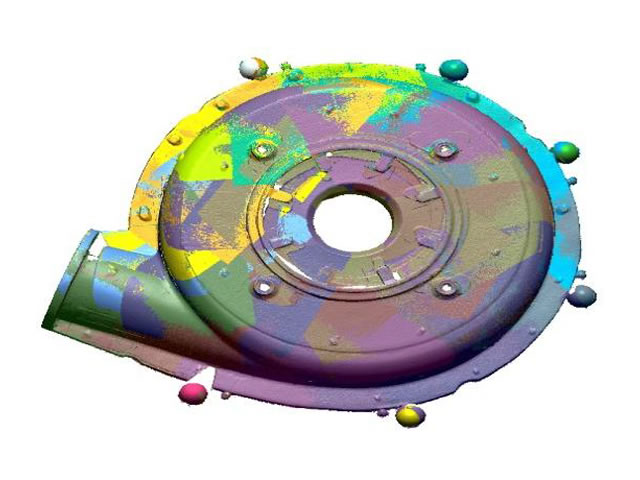

- Scan Data is registered, merged, and aligned in Rapidform XOR. (Figure 2)

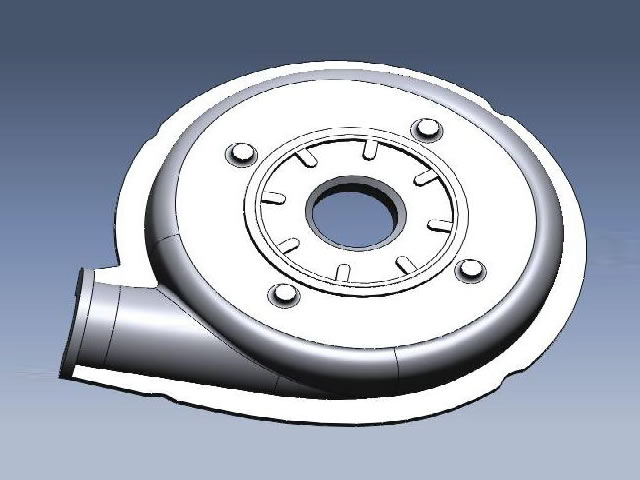

- Sketchs and curves are generated based upon the scan data in order to develop a parametric solid model. (Figure 3)

NeoMetrix Advantage:

- Geometry is modeled to original design intent.

- Organic shapes and handmade radii accurately reconstructed.

- Clean IGES file ready to be CNC machined.

Get Started Today!

Figure 1 – Scanning with Vivid 9i

Figure 2 – Scanned Data Patches

Figure 3 – Final Solid Model