Problem:

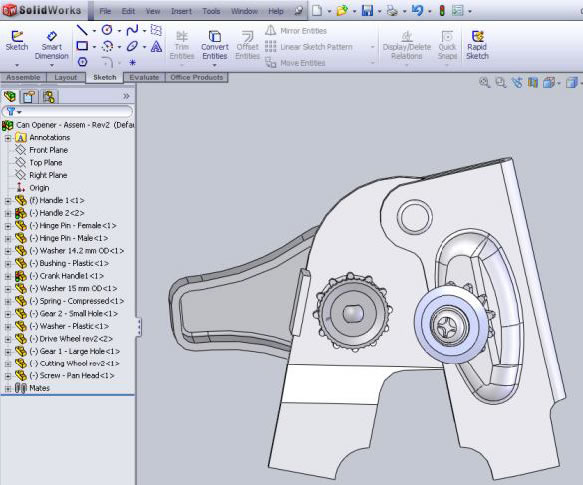

Lifetime Hoan was interested in updating the design of one of their manual can openers (Figure 1), however there were no drawings of the existing parts.

Traditional Method:

Hand measurements are normally used to pull off dimensions and radiuses. However, the complex shapes and angles were not features that could be accurately measured by hand.

NeoMetrix Solution:

- Laser scan each component with Konica-Minolta Range 7 Scanner.

- Rapidform XOR used to align and merge multiple scans.

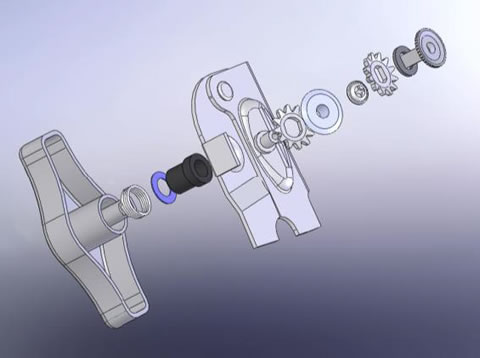

- Each component solid modeled based upon scanned data.

- All parts transferred to Solidworks for inclusion in final assembly. (Figure 2).

Benefits of NeoMetrix Solution:

3D scanning allows for the rapid capture of complex shapes, so that final CAD model development will be accurate to the original.

Get Started Today

Figure 1 – Original Part

Figure 2 – Solidworks Assembly Mode

Figure 3 – Exploded View