Reverse Engineering a Baseball Bat

The Problem:

Professional baseball players are very particular when it comes to the fit and balance of their bats. One player may prefer their grip to be thinner than normal, another may like more weight in the barrel, or a larger knob. These features can be honed on an individual blank to the player’s taste, however the problem arises when this unique profile must be duplicated. A player will need quite a few bats, and all must match to give the most consistent performance possible.Traditional Method:

Traditionally, a baseball bat is replicated with the aid of a lathe duplicator. This works fine, but is a more manual, tedious process. It also requires a large fixture that is less than ideal for portable applications. The bat is locked in place, then a tool is dragged down the profile of the bat to produce the proper curve. Because of the drastic change in geometry where the grip of the bat meets the knob, the tracing of both profiles must be done separately, then manually matched up in the accompanying software, leaving room for error. This profile curve is then converted into a format for the CNC to read. The entire process requires an hour or two.NeoMetrix Solution:

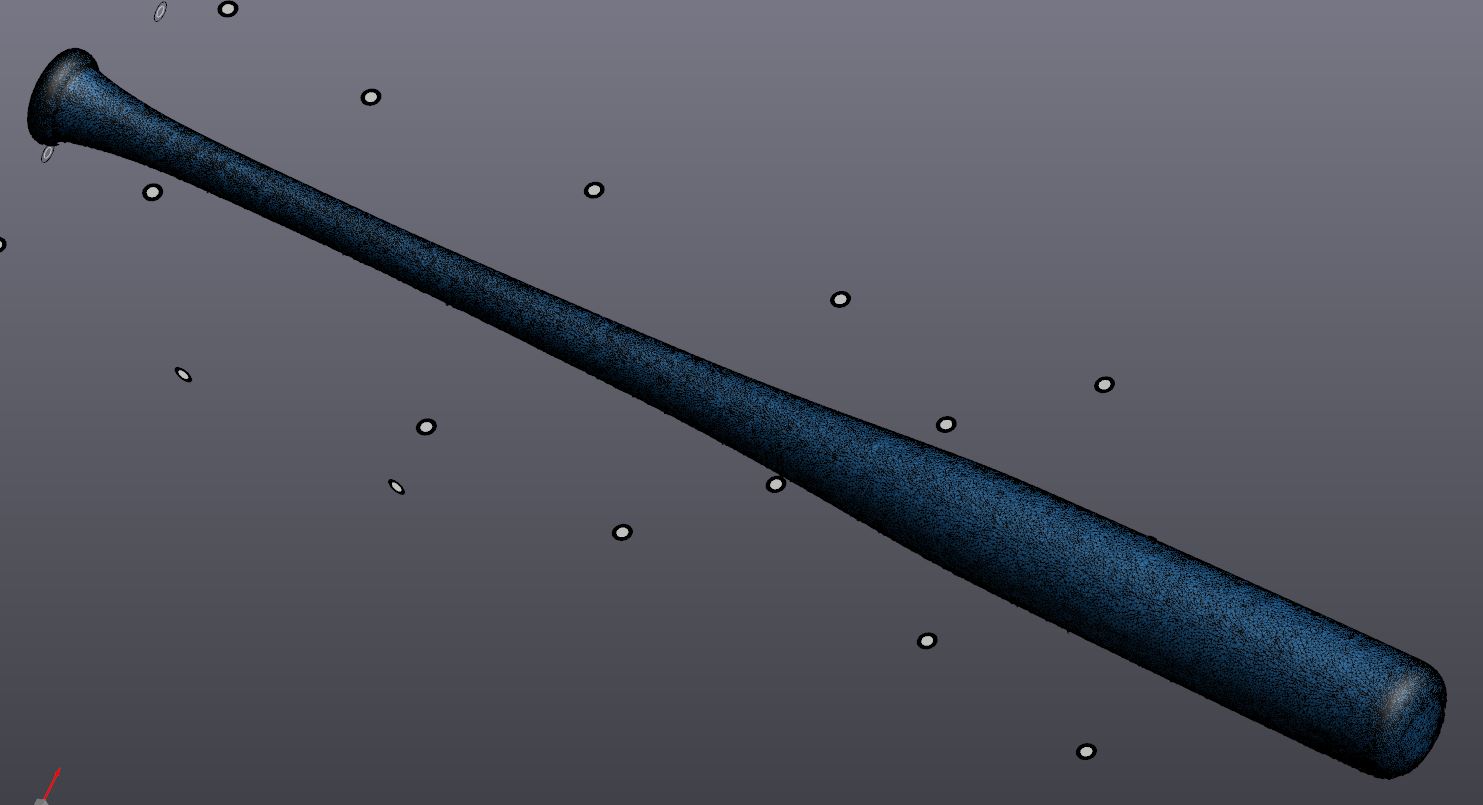

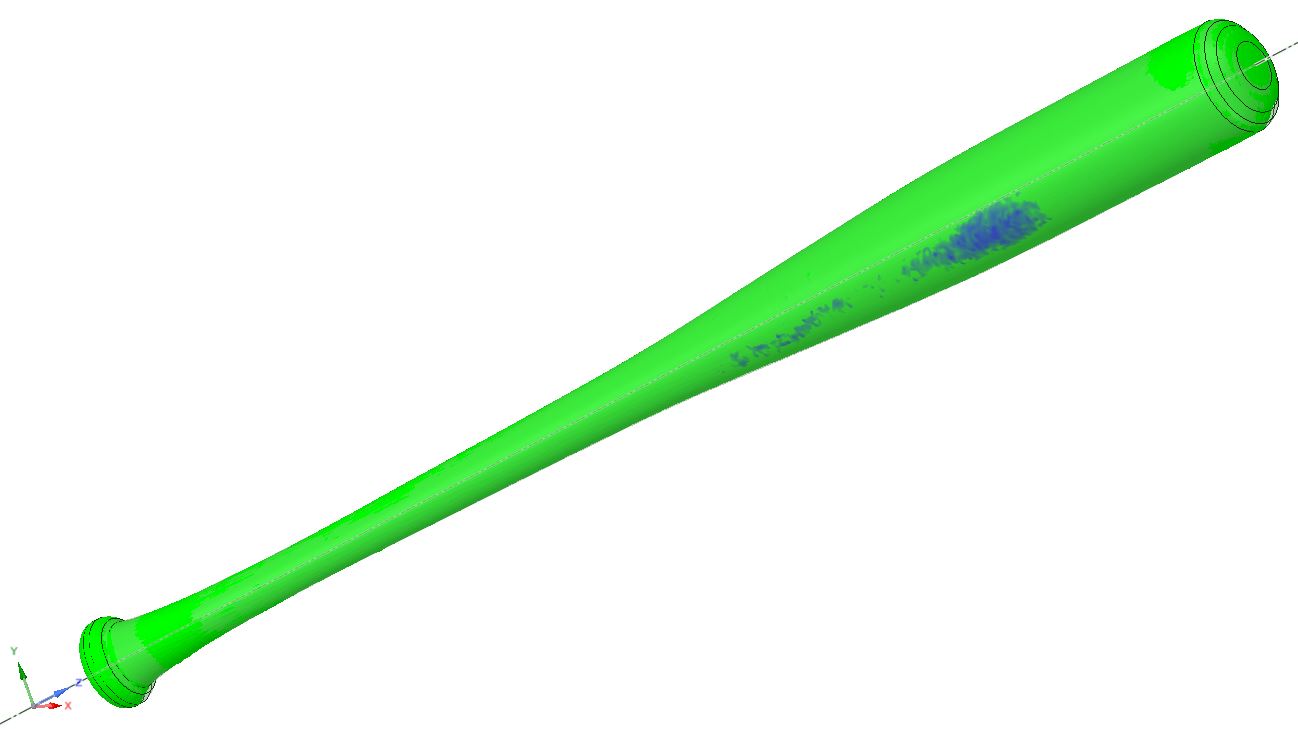

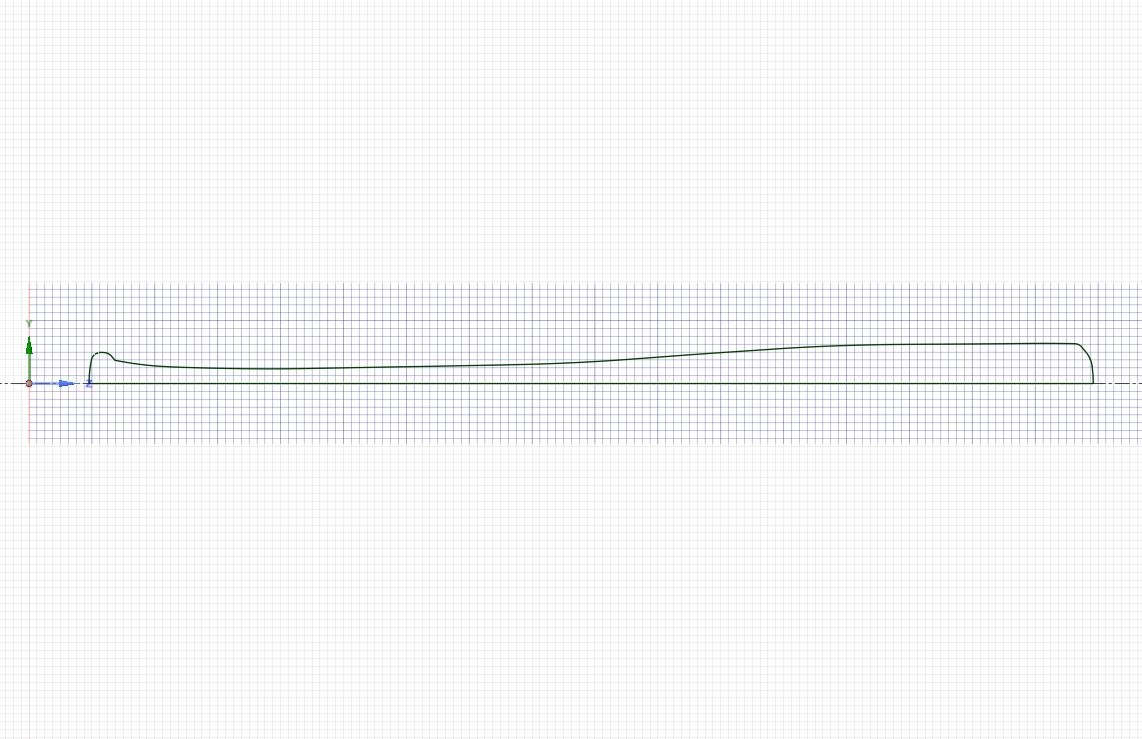

The geometry of the bat was captured using Creaform’s most affordable hand-held 3D scanner – the Go!SCAN 50. With a stated accuracy of 0.004″, the Go!SCAN was more than capable of providing exceptional data for the reverse engineering process. The accurate mesh of the bat was then brought into ANSYS SpaceClaim Engineer, an extremely affordable software with true reverse engineering capabilities. SpaceClaim allows the user to cut a cross section through the mesh, and trace the bat’s exact profile. This profile was then revolved and the model verified via SpaceClaim’s “Deviation” tool. Once it was clear both the center axis and the sketched profile matched the original bat precisely, the cross section sketch was ready for the CNC machine.NeoMetrix Advantage:

From start to finish, the entire process of scanning, modeling, and exporting a cut profile for the bat took less than 30 minutes. This speed is made possible by today’s advanced hardware and software technology. Creafom’s hand-held 3D scanning solutions are the fastest available, and their accompanying scan acquisition software, VX Elements, rapidly and automatically generates a triangulated mesh for more efficient downstream applications. Creaform scanners do not require heavy fixtures or ridged setups. They are light and compact, allowing them to be taken on location if the situation requires it. SpaceClaim’s revolutionary direct modeling workflow, paired with its true reverse engineering capabilities, have made the creation of 3D models from scan data quick and easy, even for the novice user.Watch: 3D Scanning

Baseball Bat 3D Scan Data

Baseball Bat Model

Baseball Bat Profile for CNC