Reverse Engineering an Aircraft Nose Gear

The Problem:

With older aircraft, there is usually very limited existing documentation or data on parts and tooling. When a tool breaks, or is worn out, making a new one is not as simple as sending a CAD file to a machinist.Traditional Method:

Traditionally, the old drawings and existing parts would be used as a reference to reverse engineer a part, and then a tool. With a component that has many non-geometric shapes, and complex curvature, it is very hard to accurately recreate a part. Hand measurements can only be so accurate. Measuring the old tool may not be an option, due to damage, wear, or the tool might not even exist anymore. When it is a precision part, assumptions cannot be easily made, so engineers have to do trial and error until they achieve a close representation of the original part. Trial and error is an extremely costly method of development.NeoMetrix Solution:

With the Neometrix Method of 3D scanning and modeling, the part can be easily reverse engineered, ensuring high accuracy, saving time, and saving money.Scanning:

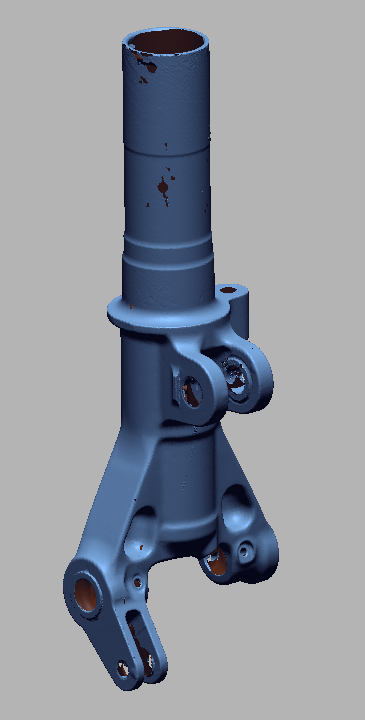

A Handyscan 3D scanner was chosen to scan the nose gear. The Handyscan is perfect for capturing details on parts that are too large or oddly shaped to be easily scanned on turntable based scanners. The part was covered in reference “dots” and then scanned in a matter of minutes. With the Handyscan, it is easy to collect data in small, hard to reach areas, like holes and grooves. The data was then processed within VX Elements, the scanning software, producing a clean and accurate mesh model (Fig. 1).Modeling:

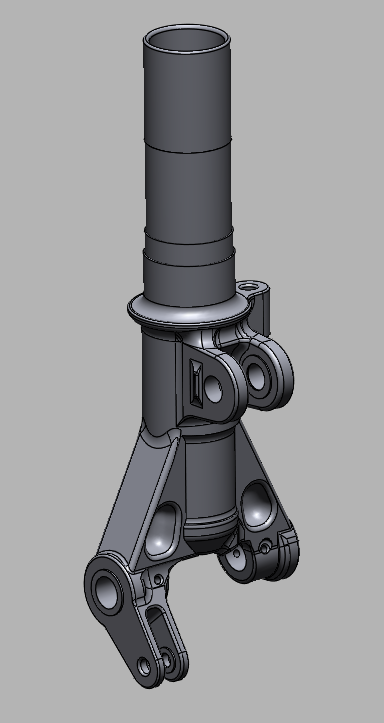

The scan data was then imported into Geomagic DesignX reverse engineering software. With this software, a complete 3D model was built. This was done by extracting key geometry in the form of sketches, which can then be used to generate model features. The developed model was then compared to the scan data to ensure all features were modeled correctly and accurately. The solid model was then exported as STEP file and delivered to the customer (Fig. 2).NeoMetrix Advantage:

With 3D scanning, there is no compromise that needs to be made on part accuracy. All important features are fully captured and used as a guide for the reverse engineering process. 3D scanning and modeling is extremely fast and inexpensive compared to traditional reverse engineering methods. With scanners like the Handyscan, and powerful modeling software like Geomagic Design X, the entire reverse engineering process takes less time and money to complete. Rather than the delivery of a list of measurements, or drawings, receiving a full CAD model that can be easily imported into any major CAD software allows companies to better organize, modify, and improve designs in the future.

Figure 1 – Raw scan data from Handyscan

Figure 2 – Modeled solid that can be exported as a STEP or other common file types.