Restoring Vintage Toys with 3D Printing

Discover Your 3D Solutions!

The Problem:

We all have memories of our favorite toys from childhood. Sometimes these special friends can last a lifetime.. but sometimes they do not age very well. Planes, trucks, & dolls can all suffer the effects of time and the mistreatment that goes along with being a toy. In this case Tina the doll lost her leg, and her owner was interested in having it replaced.

Traditional Method:

In some cases, pieces and part for classic toys can be sourced on the internet. Spare or replacement parts can be purchased, or salvaged from items that are broken in other ways. In this case, a suitable replacement part could not be found.

NeoMetrix Solution:

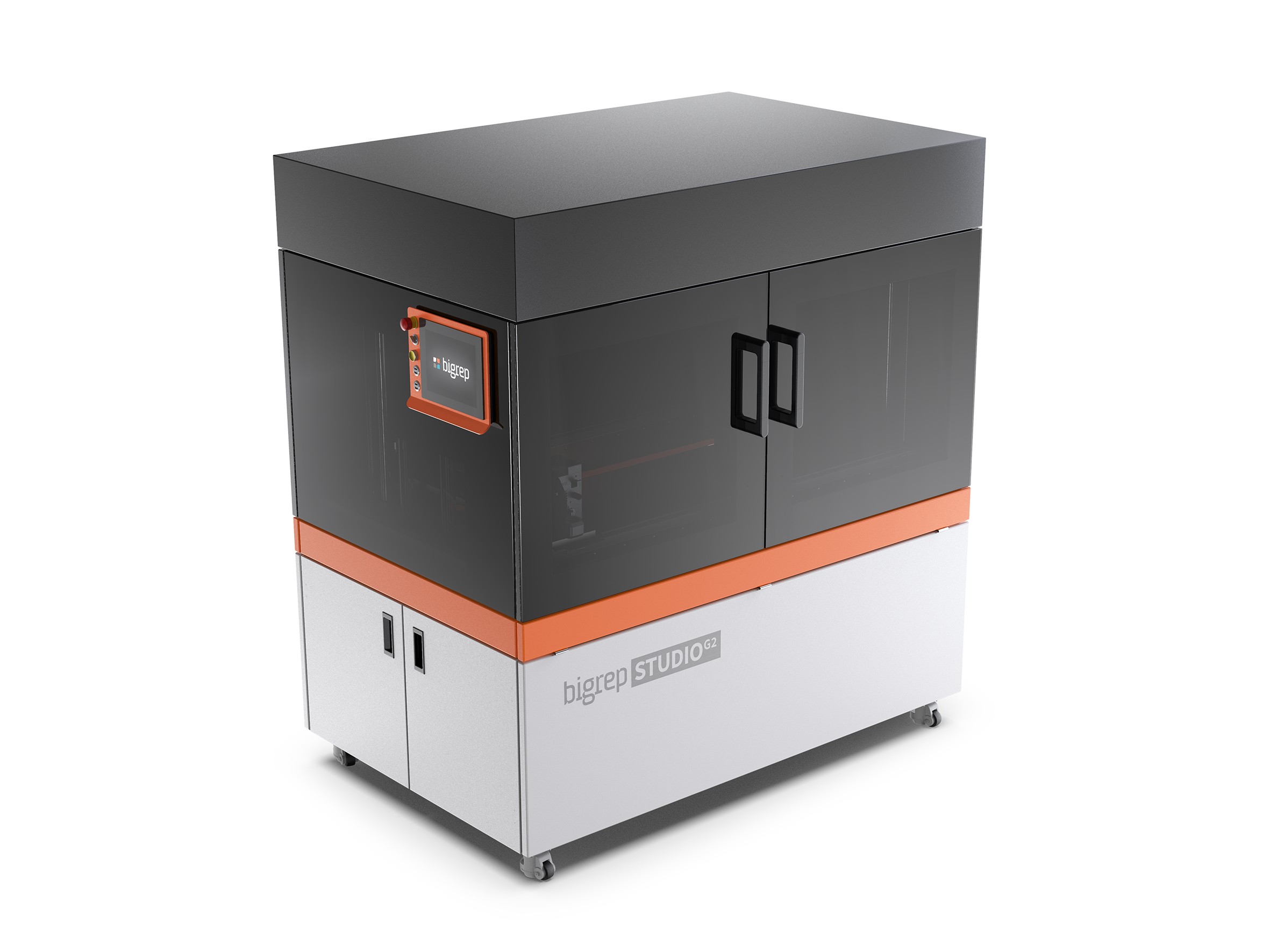

Since Tina was missing her right leg, but the left leg was intact, we were able to scan the left leg, as well as the socket for the missing right leg with the Creaform Go!Scan Spark. The left leg data was mirrored and combined with the right socket data to create a 3D STL model of the missing leg. That new leg was then printed in ProHT, an ABS-like bio polymer on our BigRep Studio G2 3D printer. Tina was now whole again.

3D Scanning with Go!SCAN Spark

BigRep Studio G2

NeoMetrix Advantage:

The use of 3D scanning and 3D printing technology enables the user capture geometry of the most complex shapes, create an accurate 3D computer model, and quickly fabricate replacement parts. In this case, this process was performed to restore a vintage toy doll, however the same concept can be used in other more serious applications such as creating prosthetics for amputees. Remaining limbs can be scanned, mirrored, then used to develop prosthetic limbs, Scanning can also be used to capture the shape of the residual limb in order to ensure a proper fit in the final prosthesis.