Repairing Sporting Goods with 3D Printing

Discover Your 3D Solutions!The Problem:

Hockey players need the right length stick to be able to play and maneuver efficiently. Sometimes players will cut their stick too short by accident and will end up having back pains from having to lean forward so much, or won’t have enough length for the best control possible. This can cause a difficult experience until an extension is either purchased or produced to get the hockey stick to the correct length.

Traditional Method:

Repair of wooden, plastic or composite hockey sticks has never been practical. The only solution is replacement. Quality hockey sticks can be expensive, and may take weeks to receive.

NeoMetrix Solution:

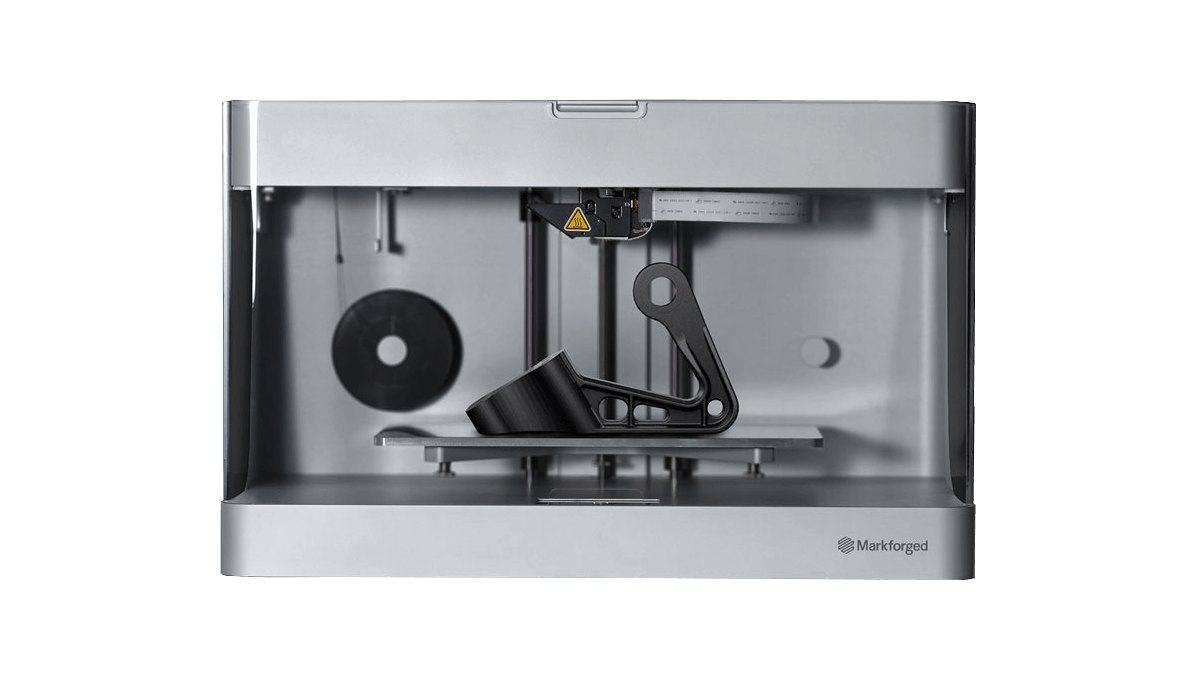

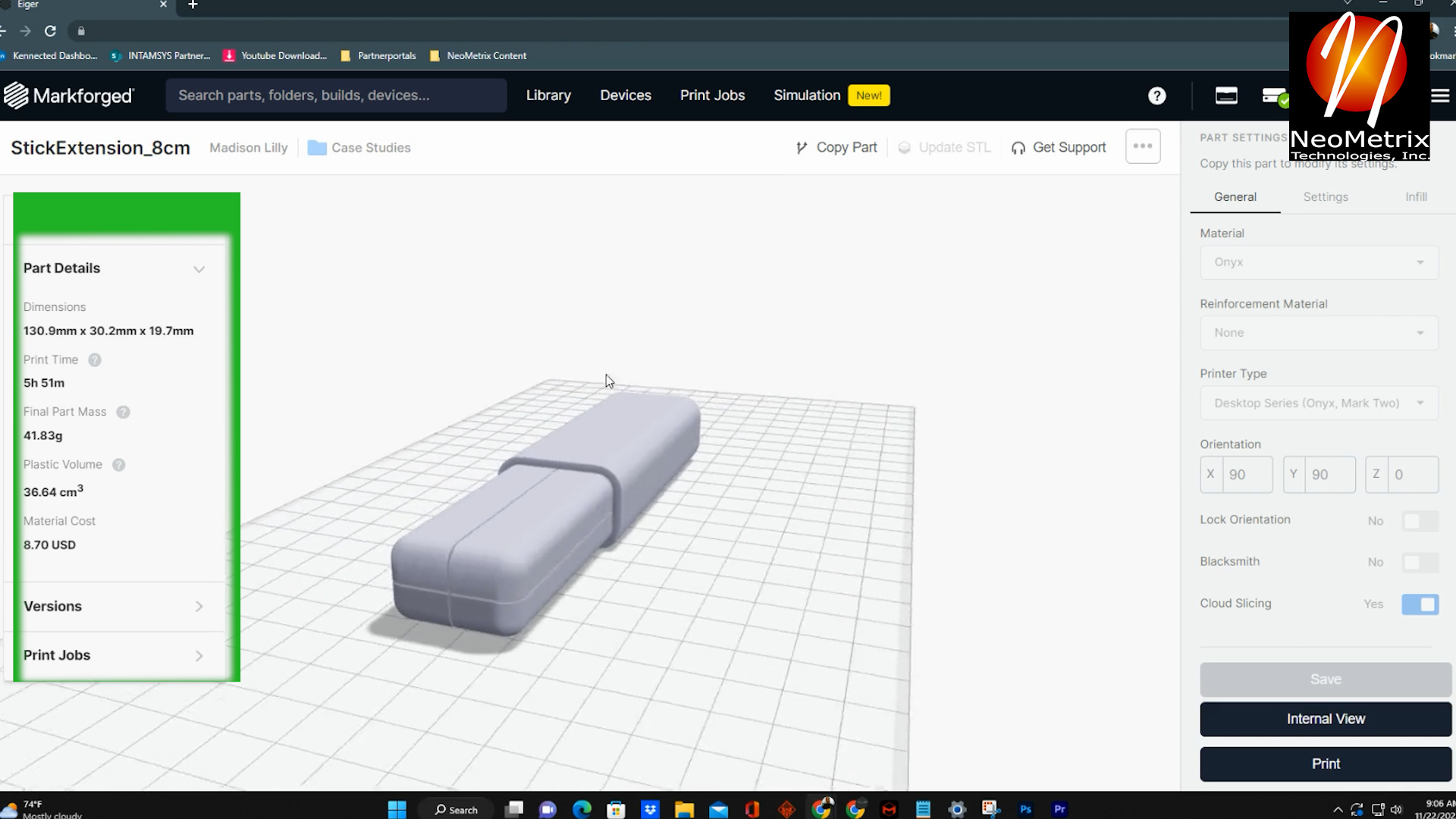

The online community has created downloadable 3D model files for extensions that can be downloaded by the public. We were able to find the right size/length extension and 3D printed it on our Markforged Mark Two desktop machine. With the addition of the desktop cloud software Eiger, users can fully prepare and analyze prints with ease. The result looked like a professionally manufactured part!

If the appropriate file is not readily available, there is another solution: 3D Scanning. Very simply, hockey sticks can be 3D scanned with tools such as the Creaform HandySCAN Black Elite, which would provide a precise data set. The data from the scanner is exported as STL, and in many cases, can be sent right to the 3D printer with minimal editing.