Overcoming Supply Chain Challenges with 3D Scanning & 3D Printing

Discover Your 3D Solutions!The Problem:

Our customer had a custom leveling screw come loose in their large format printer, causing it to fall onto the printer bed, get dragged by the print head and get bent. Unfortunately, our supplier here in the U.S. was out of stock for this item, and a replacement would have to come from Germany. This meant that the machine would be down for at least a week while a replacement was in transit.

Traditional Method:

Since this is a custom part, the only option is to wait.

NeoMetrix Solution:

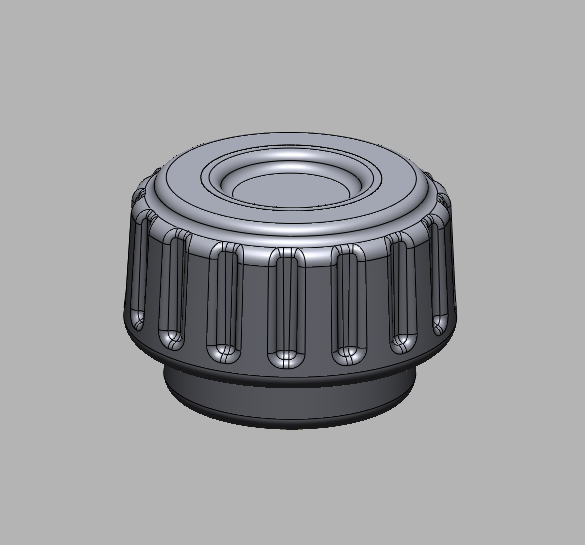

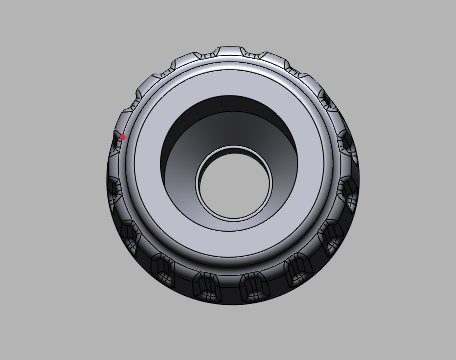

In consult with the manufacturer, our engineering team determined that the thread on this screw is a metric standard. We were able to scan the original knob with our HandyScan Black Elite 3D scanner, and reverse engineer the item to work with an off-the shelf metric screw. We used Geomagic Design X to model the exterior geometry to exactly match the original part, but work with an off-the shelf screw. The final design was 3D printed on our Markforged Mark Two 3D printer. The result looked like a professionally manufactured OEM part.

3D Scan Data from

HandySCAN Black Elite

Reverse Engineered in

Geomagic Design X

Reverse Engineered in

Geomagic Design X

3D Printed on

Markforged Mark Two