How NeoMetrix Utilized 3D Scanning to Revolutionize Complex Part Manufacturing

Transforming Complex Volute Manufacturing with 3D ScanningTHE PROBLEM

Thompson Pump manufactures durable hydro-pumps for applications all over the world, with machines running for years, into decades. To support their customers, Thompson Pump must service and repair worn equipment with newly-manufactured components whenever necessary. Unfortunately, some older designs were managed by suppliers who are no longer in business, or have discontinued the manufacture of components. In this case, the design and manufacture of a specific model of impeller and volute were no longer available. Therefore, Thompson Pump needed a high-quality, modern 3D model of each component to continue the support this early-model pump.

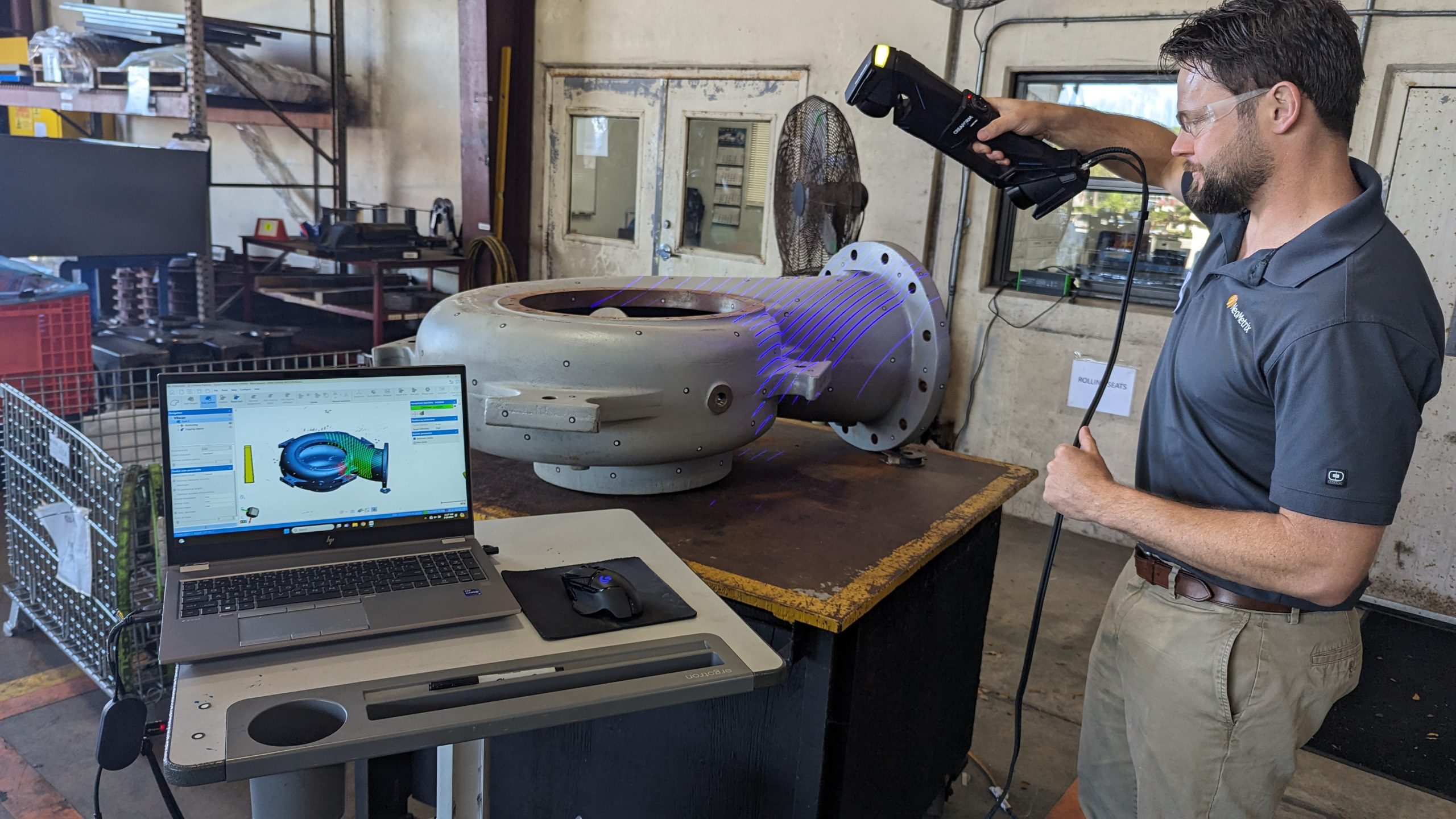

A high-accuracy 3D scan using the HandySCAN MAX can take just minutes!

TRADITIONAL METHOD

Thompson Pump has an articulating arm CMM in-house that is used for checking profile tolerances. While this is adequate for identifying surface deviations at very specific locations, the sparse data points collected by the arm made accurate reproduction of the complex surfaces extremely difficult and time consuming. One must somehow map a very complex surface within these data points manually, then hope the areas between points are accurate to the real part, as these areas are void of data.

NEOMETRIX SOLUTION

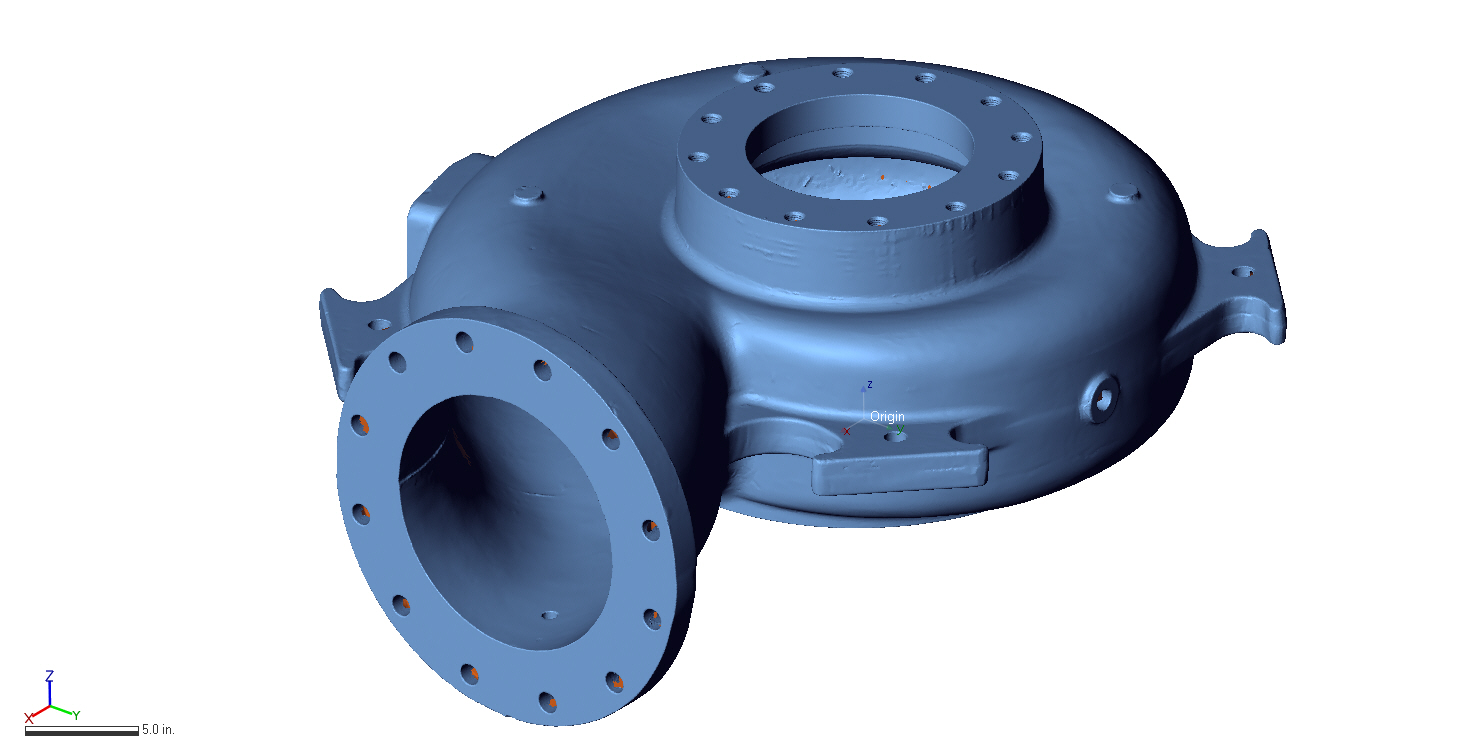

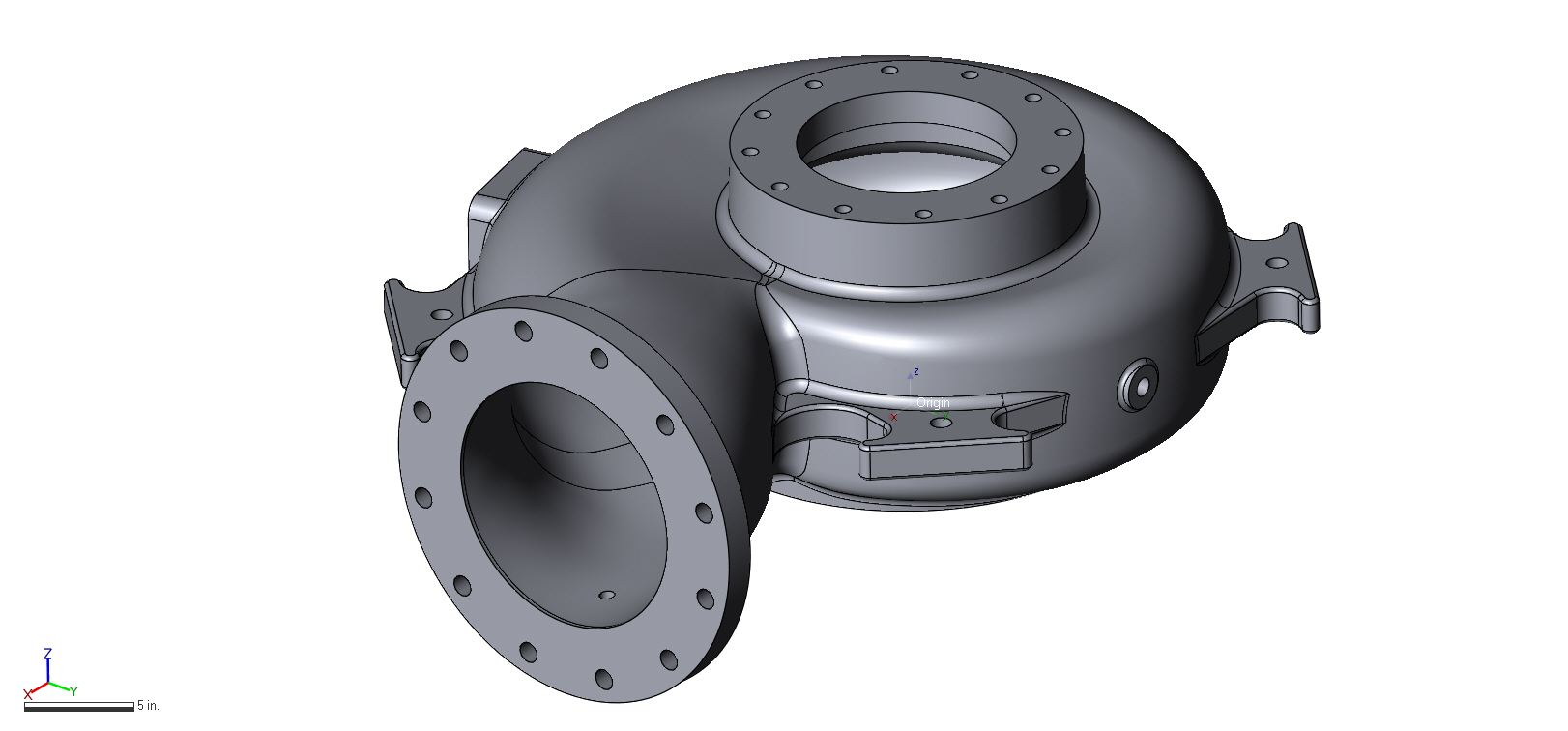

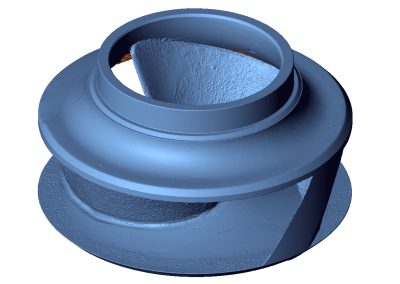

Thompson Pump contacted NeoMetrix Technologies to capture the complete surface data of the impeller and volute, then provide an extremely accurate feature-based 3D CAD model. The smaller Impeller was scanned with a Creaform HandySCAN Black|Elite handheld model to take advantage of its Single Line mode, allowing the scanner to reach the smaller, harder to access recesses and interior cavities of the part. For the larger volute, the new HandySCAN MAX|Elite was selected for its much larger scanning volume and faster data capture.

Process:

- 3D Scanning: The HandySCAN MAX Elite provided high-resolution scans, ensuring comprehensive coverage of the volute’s intricate geometry.

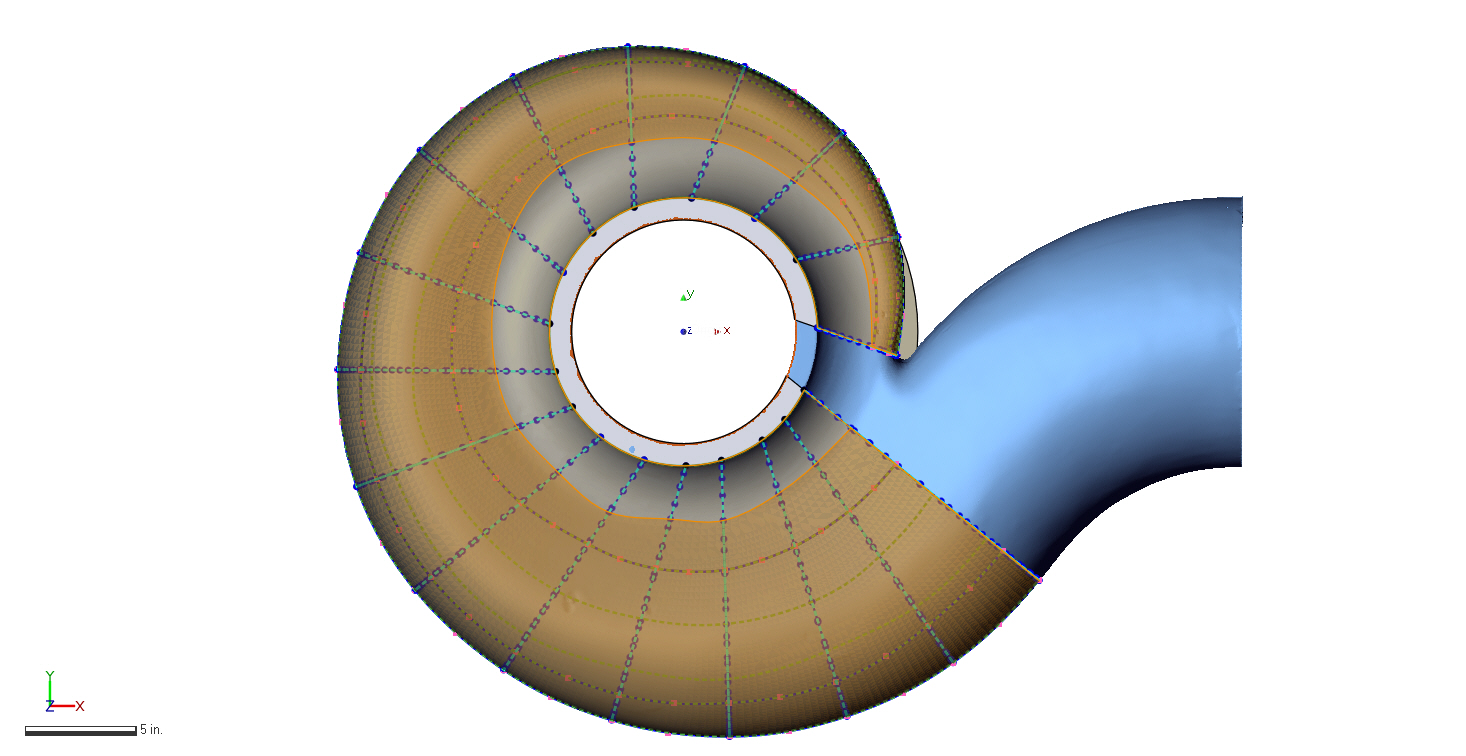

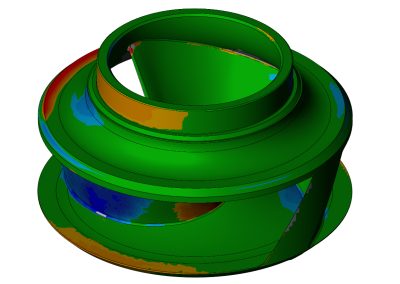

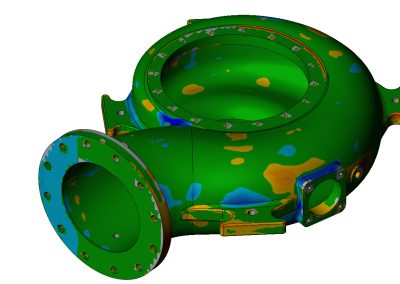

- Data Processing: Using Geomagic Design X, we harnessed automated and guided surfacing tools, including the Loft Wizard, to efficiently recreate the volute’s complex inner and outer surfaces.

- CAD Creation: The processed scan data was used to generate a solid CAD model, perfectly replicating the original volute.

Both near-watertight scans were then imported into Geomagic Design X for reverse engineering. The complex surfaces of the impeller blades and exterior/interior Nautilus-like geometry of the volute were tackled with the invaluable Loft Wizard tool, which applies an interactive and automated parametric loft across freeform geometry. The remaining features and radii were added to complete the models, and fine-tuned with the Accuracy Analyzer tool, which displays surface deviation data across the surfaces at any point during the modeling process.

NEOMETRIX ADVANTAGE:

Contact NeoMetrix

Ready to revolutionize your manufacturing process? Contact NeoMetrix today to learn how our 3D scanning solutions can meet your complex production needs.