Designing & 3D Printing A Drip Tray

The Introduction:

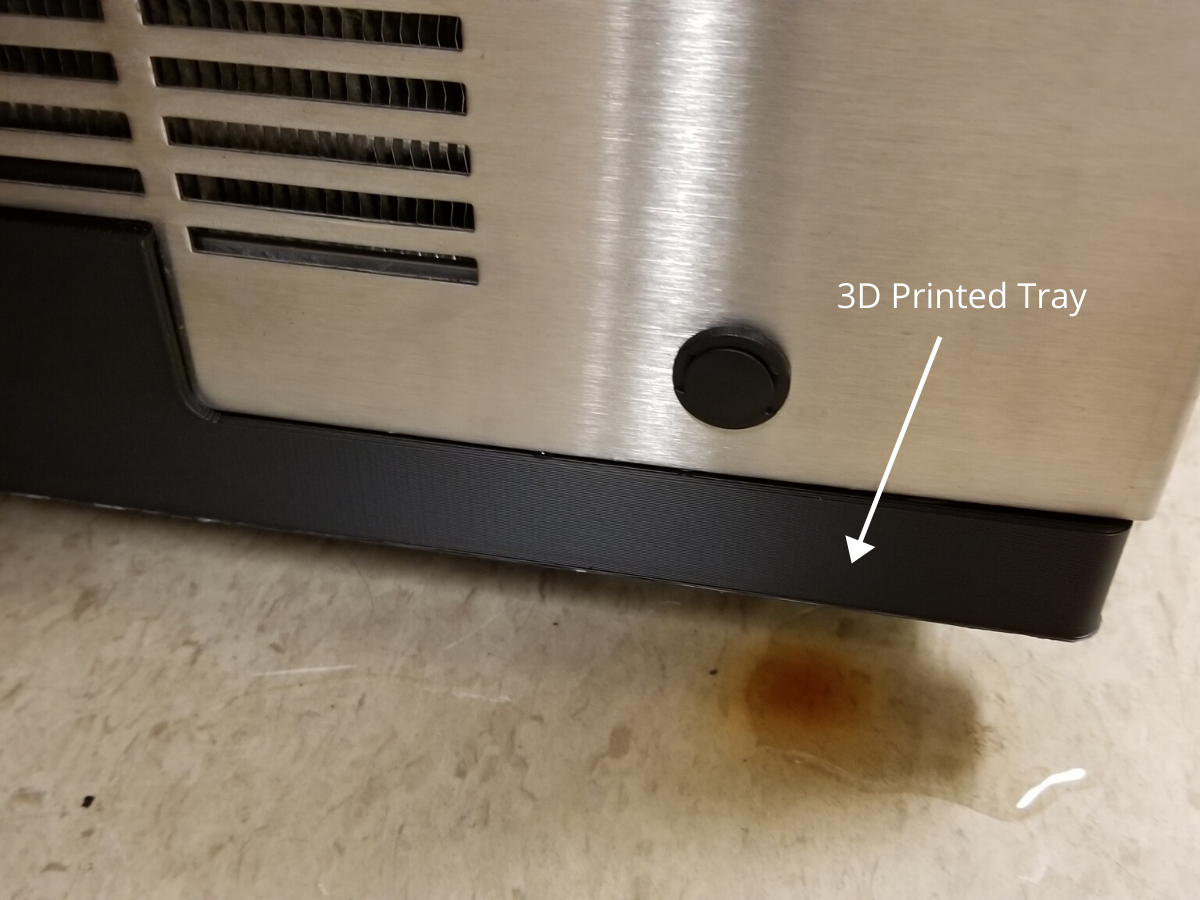

In this in-house project, we designed and 3D printed a custom tray to protect one of our devices.

The Problem:

A piece of equipment we use for post-processing parts started to produce water due to condensation on a compressor. Most of the time this water would evaporate before collecting. However sometimes this water would pool on the ground causing a slipping hazard.

Traditional Method:

Traditionally, the easiest option would be to place a tray under the device. However, this option is inelegant. Additionally, since the device is on wheels, whenever you move the device one would need to adjust the tray.

NeoMetrix Solution:

With the design software, 3D printers, and design skills on-hand at Neometrix, we were able to design and 3D print a drip tray using BigRep Studio. The tray is made out of ProHT material and attaches directly to the piece of equipment.

NeoMetrix Advantage:

The in-house capabilities of NeoMetrix allow for rapid development, testing, and deployment of sleek

solutions to common or niche problems. The engineers, along with several different software packages

allow for the development of solutions. The range of 3D printers, printing in many different materials and sizes, allow for almost immediate testing of the designed solutions. NeoMetrix is capable of assisting in the design process from start-to-finish.

Tray Model ➜ 3D Printed Tray