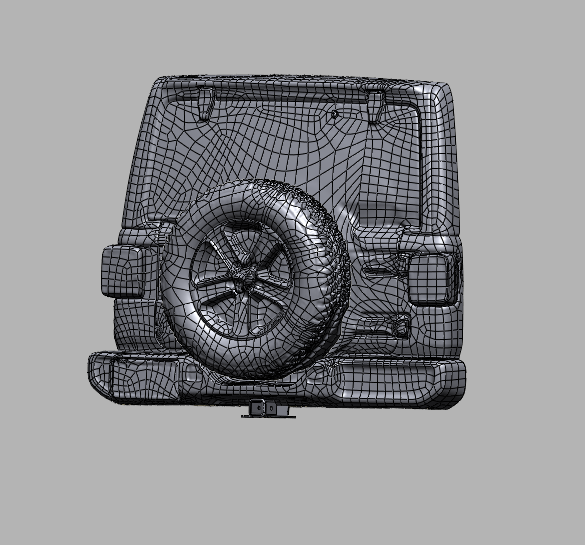

3D Scanning and Rapid Surfacing for Aftermarket Product Development

Design custom fit parts for applications across every industryTHE PROBLEM

Our client, Rugged Essentials, is developing aftermarket accessories for the popular Jeep Wrangler. Aftermarket automotive manufacturers

TRADITIONAL METHOD

Historically, aftermarket designers used a variety of hand measurement methods to capture the required dimensions of the existing car and truck parts. These include calipers, tape measures, and cardboard templates. Manual measurements were then fed into the designer’s CAD system in the computer. Unfortunately, manual methods are prone to errors, and automotive shapes are very difficult to measure by hand. This results in several prototype designs being required in order to ensure a good fit for the final parts onto the vehicle.

NEOMETRIX SOLUTION![]()

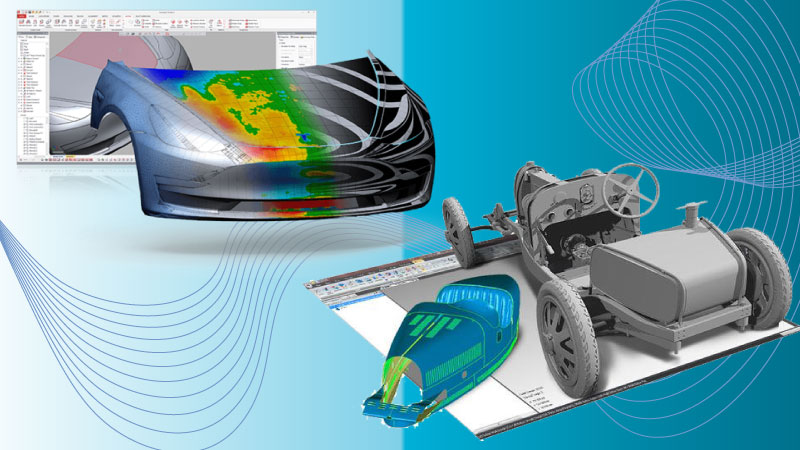

NeoMetrix utilizes portable hand-held data capture devices like the Creaform Go!SCAN SPARK 3D scanner. With just a few minutes of setup time, we are able to generate highly detailed physical scan data with accuracy of 0.05 mm (0.002 in). The entire vehicle can be captured in just a few hours, generating a precise polygonal mesh (STL) which represents the original shape of the car or truck. STL files can then be used in software products like Geomagic Wrap and Geomagic Design X to be able to produce a Final CAD models for use in the design of new parts.

Creaform Go!SCAN Spark

3D Scanner

Geomagic Design X

3D Software

Geomagic Wrap

3D Software

Custom Aftermarket parts are trending in today’s automotive industry.

YOU CAN CUSTOMIZE:

EXTERIOR: HOOD, GRILL, DOORS, DOOR HANDLES, SPLASH GUARDS, FENDER, ROOF RAIL CROSSBAR, + MORE

INTERIOR: CARGO MAT FLOOR LINERS, CENTER CONSOLE, + MORE

NEOMETRIX ADVANTAGE

There are many advantages to using the NeoMetrix solution. Not only is 3D scanning far more accurate than hand measurements for documenting complex shapes, the data is automatically stored in a 3D format eliminating the errors associated with manual data entry.

This digital shape capturing also allows manufacturers to produce parts more quickly and more accurately, improving production speed and reducing time to market.