3D Scanning and Silicone Casting

Capture & Produce Geometry: Inside & Out | 3D Printing the Final Product in PEEK Discover Your 3D Solutions!THE PROBLEM

Our customer is a worldwide manufacturer of laboratory equipment. They often deal with containers that need to connect via a threaded coupler. Being worldwide, this sometimes means one container has english threads (or standard, here in the U.S.), and the mating component as metric threads. These custom couplers are often purchased items, however with the all the supply chain issues plaguing industry over the past year or so, they have decided to reverse engineer some of their current designs and use a 3D printer to manufacture these items in house.

TRADITIONAL METHOD

Reverse engineering complex parts by hand can be challenging, especially with items that have internal geometry or non-standard geometry such as metric bottle threads.

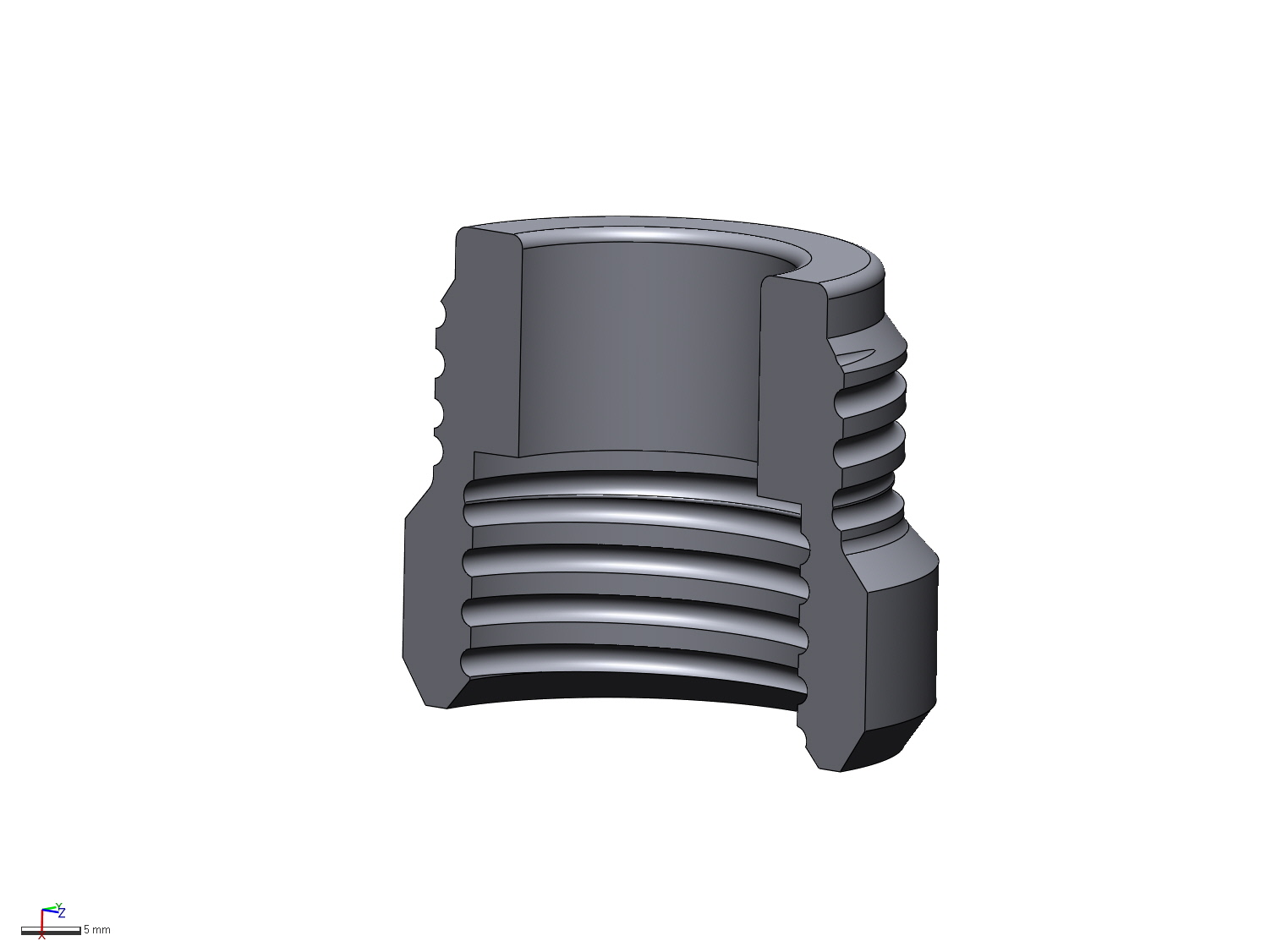

Silicone Cast of Internal Threads

Original & 3D Printed PEEK Replacement

Assembly Showing a Perfict Fit

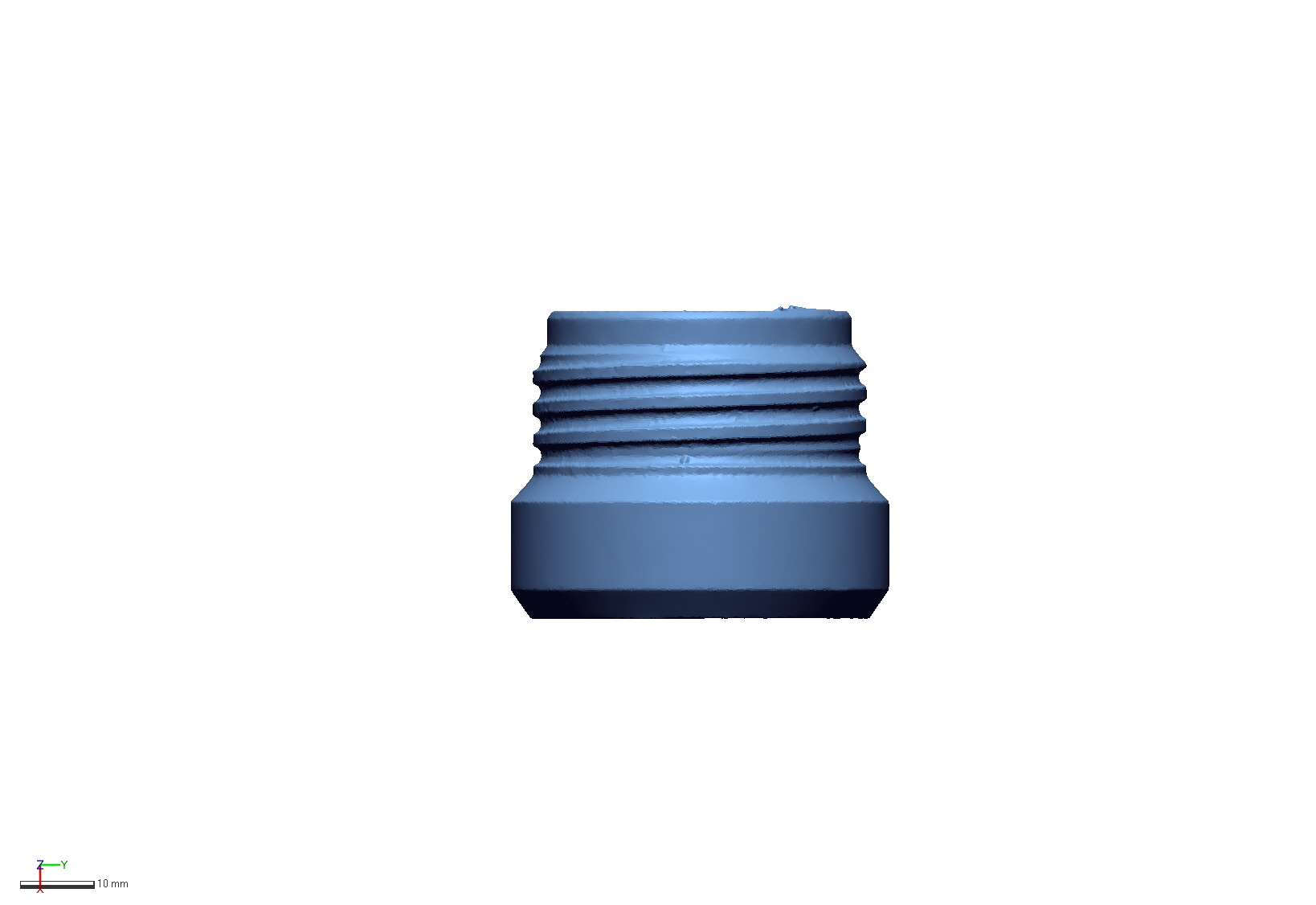

Exetrior Scan Data

Silicone Cast

Final CAD Model

Section View Final CAD – Showing Internal Threads

Other Food Safe 3D Printing Materials:

PLA, PP, co-polyester, PET, PET-G, HIPS, and nylon-6, as well as some brands of ABS, ASA, and PEI

NEOMETRIX ADVANTAGE

3D scanning combined with silicone casting allows for the capture of the most complex geometry: inside and out. Geomagic Design X enables the user to then quickly create CAD files to document existing parts, and finally, 3D printing on the INTAMSYS 410 allows for in-house manufacturing eliminating supply chain issues.

INTAMSYS FUNMAT 410

Geomagic Design X

HandySCAN Black Elite