3D Scanning a Race Car for Computational Fluid Dynamics

Advanced Composites Develops New Methods for CAD Model CreationUpon updating a car body design, a racing team will need to know how the new geometry will affect the air will flow around the vehicle when in motion. Wind tunnel testing has always been a time consuming and expensive endeavor.

Traditional Method

Traditionally, a team must drive their car on a truck to a location where they may access a wind tunnel. Upon arrival, the typical cost per hour to gain admission for use can fall between $700 and $1000 per hour. Two days of travel, and a full day of testing make this a very expensive process.

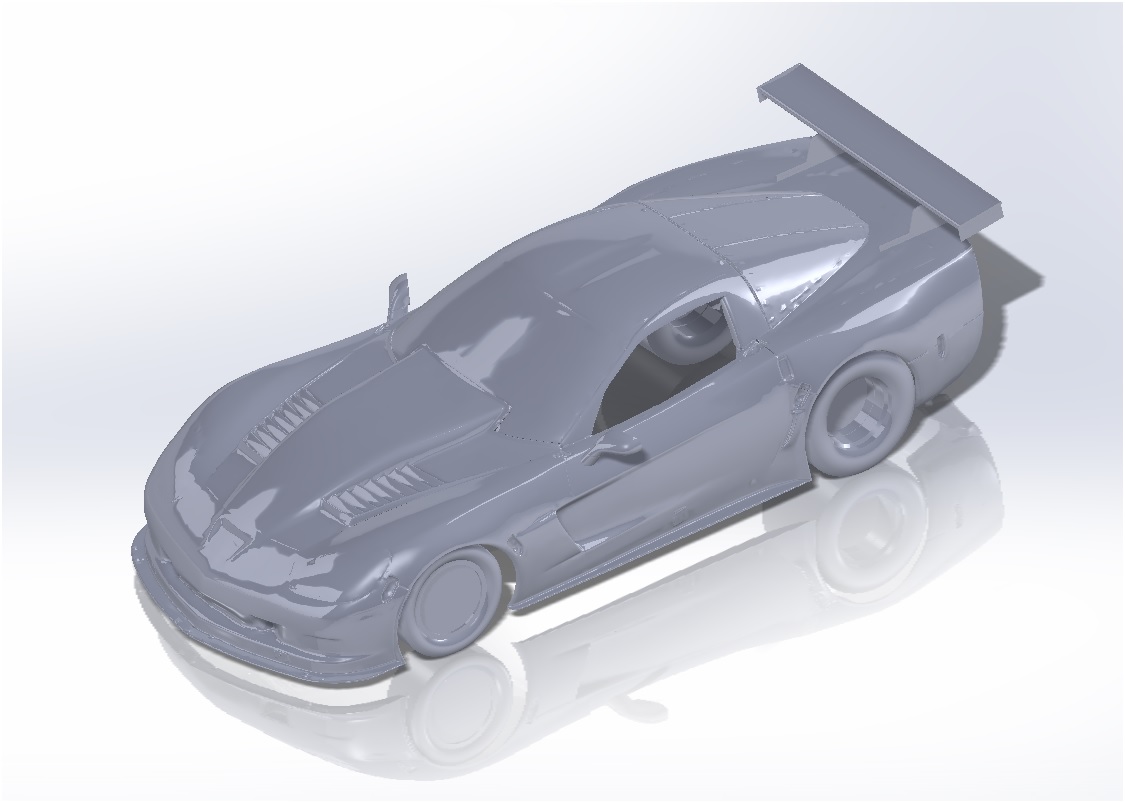

NeoMetrix Technologies determined that by 3D scanning a car and create a 3D model, an actual wind tunnel test could be replicated digitally using a fluid flow analysis software. The scanner of choice for this project was Creaform’s HandySCAN 700.

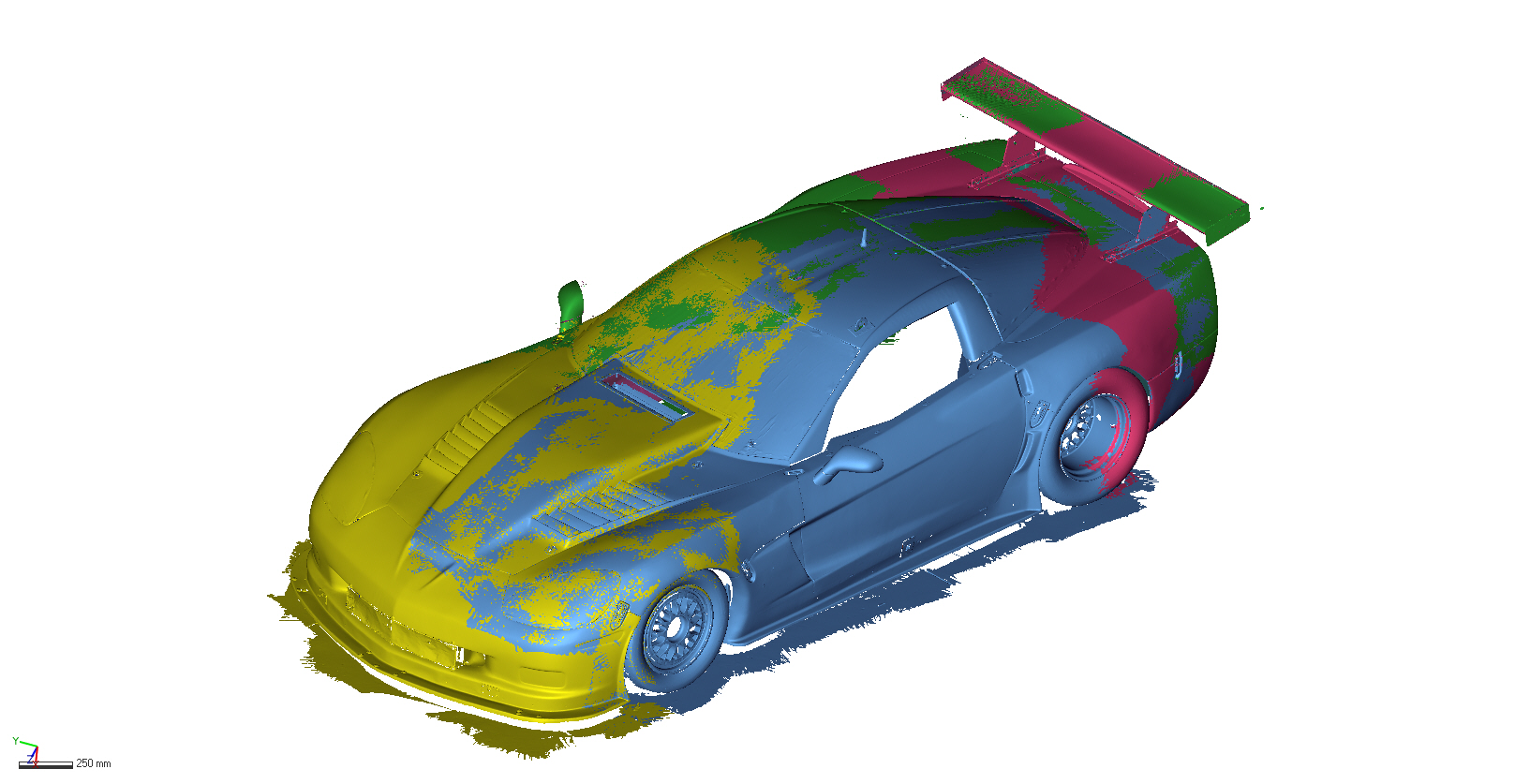

The car was scanned into Creaform’s VX Elements acquisition software., where the captured data was directly outputted as a triangulated mesh.

The exported 3D model was sent to Advanced Composites, where it was run through an air flow simulation software. This theoretical data was compared to the data previously collected by Advanced Composites during an actual wind tunnel test. Upon observing the resemblance of the outcomes, it was determined the method proposed by NeoMetrix Technologies, Inc. to be an acceptable substitute.

A typical wind tunnel test would cost an engineering team between $7000 and $10000 for a full day of access, plus the cost to transport the vehicle to and from the wind tunnel’s location. The initial cost of bringing 3D scanning technology in-house could be recouped only after a handful of scans. If a team has this process conducted by a 3rd party as a service, the savings and convenience are also readily apparent.

An additional benefit to the 3D scanning method would be the customer’s continuous access to their car’s true geometry. If for some a test that would need to be re-run, maybe for an added/changed feature, this can be completed at the customer’s convenience.