3D Scanning & 3D Printing Helps Medical Device Distributor Keep Critical Equipment Running

Complete 3D Scanning, 3D Printing, and Reverse Engineering Solutions Contact NeoMetrixTHE PROBLEM

Tropitronics, Inc. is the United States distributor for the Microwave Plasma Defroster manufactured by Ark Bio-Medical. This device quickly thaws fresh frozen plasma (FFP) for use in a variety of medical applications: FFP is a common form used in transfusions. It’s quickly frozen after collection to preserve clotting factors and proteins.

Emergency Situations:

FFP is used to treat patients with severe liver disease, clotting factor deficiencies, or those undergoing massive blood transfusions, helping to restore blood volume and clotting ability, according to Red Cross Blood Donation.

Restoring Blood Volume:

Plasma transfusions can help patients with significant blood loss, preventing shock and supporting overall circulatory function, says the Red Cross.

The Microwave Plasma defroster is a much faster thawing method as compared to slowly thawing the plasma in a warm water bath.

Over time, however, key components of the system can wear or break and need to be replaced. Replacement parts are costly, with long lead times, meaning end users may not be able to use their devices when they’re needed most.

Original Parts

Original Parts in Next Assembly

TRADITIONAL METHOD

Previously, replacing worn or broken components of the Microwave Plasma Defroster required sourcing OEM parts, often involving high costs and extended lead times. In some cases, parts were no longer available, forcing customers to cannibalize units or face downtime. Manual fabrication or machining without precise specifications was unreliable and time-consuming. These outdated approaches jeopardized the availability of critical medical equipment when it was needed most.

NEOMETRIX SOLUTION

Tronpitronics contracted NeoMetrix to reverse engineer 2 key components to this system: the plasma bag holder, and a retaining spring.

Utilizing the Creaform HandySCAN Black+ Elite 3D scanner, NeoMetrix was able to quickly capture all the geometry required to reverse engineer the parts. Data from the scanner was exported as STL, then imported into Geomagic Design X in order to develop the final 3D CAD models.

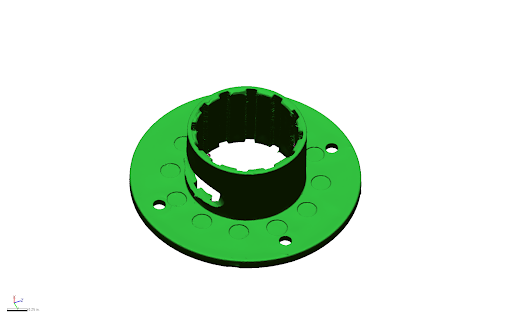

3D Scan of Bagholder

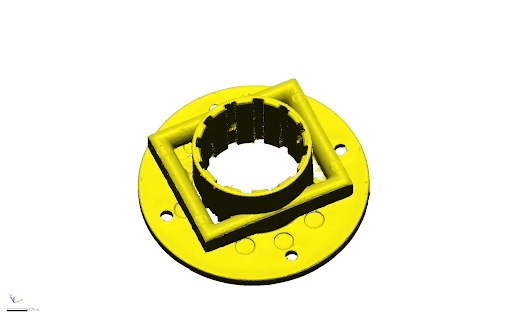

Scan of Bagholder & Retaining Spring

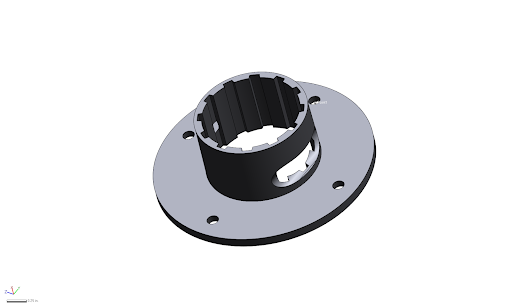

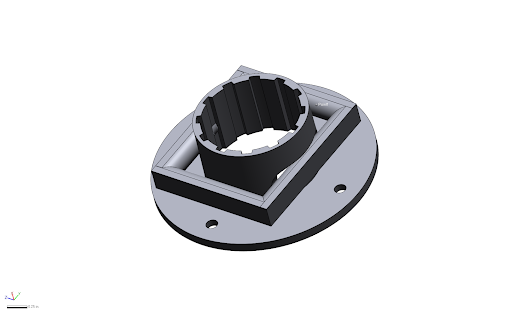

Final 3D CAD model of Bagholder

Bagholder & Retaining Spring

Once the models were completed, a first article was 3D printed on the INTAMSYS FUNMAT PRO 310 NEO 3D printer in ABS plastic. First part were shipped to Tropitronics for evaluation and testing in the device:

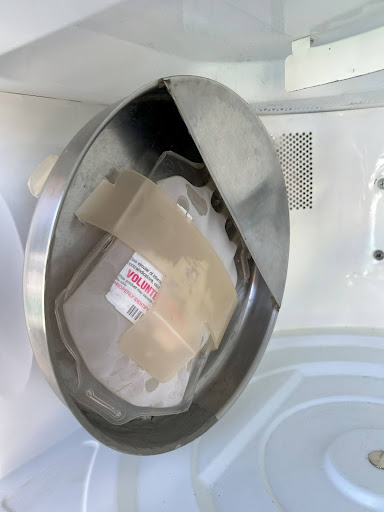

Frozen Plasma Bag in Place in the Device

3D Printed Bag Holder Installed

NEOMETRIX ADVANTAGE

The advantage in using 3D scanning is that complex shapes can be easily captured in order to accurately reproduce existing parts. This is much more accurate than using any type of hand measurements. Additionally, CAD modeling in Geomagic Design X from the scan data eliminates the human errors associated with manual data entry into a traditional CAD systems, while also allowing for incorpration of new designs. Finally, 3D printing vacuum form tooling is very cost efective and allows for quick and easy design changes, as well as manufacturing of multiple design variations simulatneously.

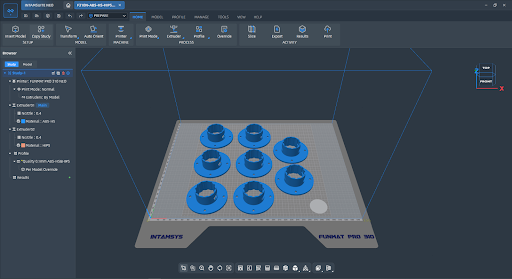

8 Bag holders ready to 3D Print in INTAMSUITE NEO

A production run of 24 sets of parts were then 3D printed and delivered to Tropitronics for inventory to help service their customers.

NEOMETRIX ADVANTAGE

The NeoMetrix approach using 3D scanning and printing technology allows for the rapid replication of worn or broken parts, which alleviates issues with supply chain and keeps critical medical devices operational, which in turn, help save lives.

HandySCAN Black+ Elite

FUNMAT PRO 310NEO