Creating Complex Parts with 3D Scanning

The Problem:

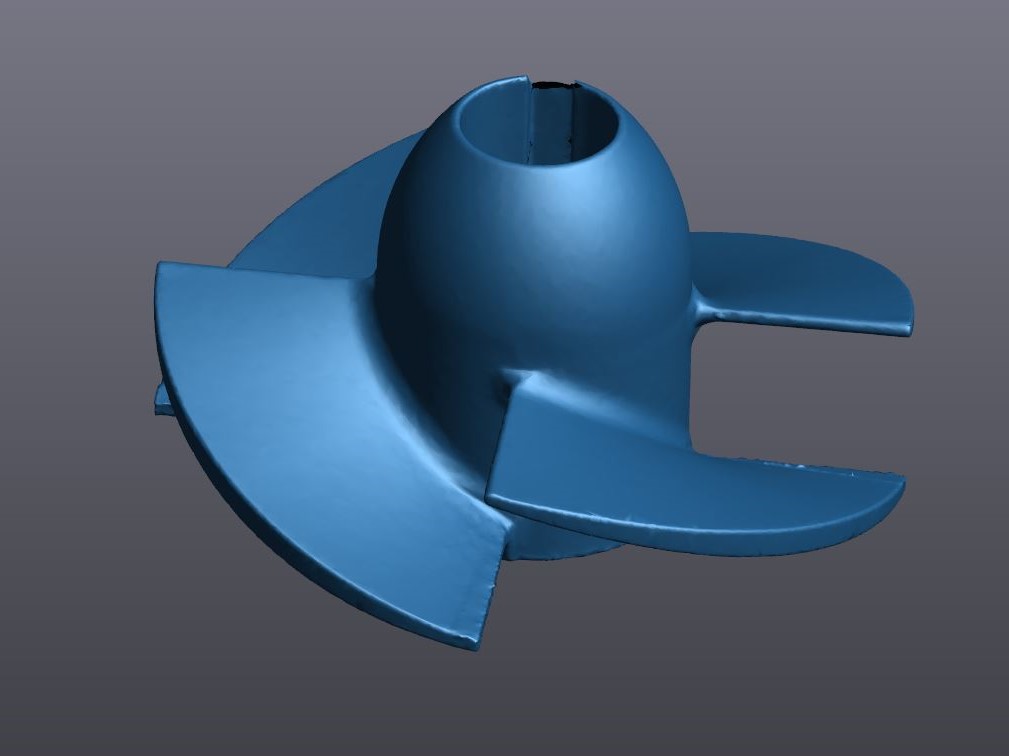

Virgil Designs is a company focusing mostly on one of a kind type projects like jet surfboards, microcomputer systems for controlling unique devices, cad design, and software design. They reached out to us to help solve their problem of creating a unique prop quickly and accurately. The purpose of the prop is for a micro water jet propulsion system used on Radio controlled boats, jet skis, and in this case a surfboard.

Traditional Method:

As with most businesses the typical method when it comes to creating unique shapes like this is going to a machine shop. This method is time-consuming and cost-effective. As well as, some shops might not be able to create shapes that are too complex. This was the case for Virgil Designs… “Due to the complexity of the prop and the fin set up a standard 3 or 4 axes CNC machine would still have trouble getting it correct.” says company CEO Arron Reninger

NeoMetrix Solution:

We used the Creafrom HandySCAN Black Elite scanner. The HandySCAN Black elite is the fastest 3D scanner in its class, extremely accurate, and provides exceptionally high resolution. We were able to provide Virgil Designs with a CAD model converted from the 3D scan taken in a matter of a few days. “The benefits for us as a small prototyping company is we can have cad files in days or even hours, then produce a usable product in days also. The world of producing a new product does not wait, someone else will do it if we don’t get it done first. Thanks to the great team at Neometrix who strive to help us pull off the impossible” says, Reninger.

NeoMetrix Advantage:

This case demonstrates some of the capabilities that we demonstrate on a daily basis:

- Highly accurate data and models.

- Digital files can be preserved for future use.

- Less expensive and time-consuming.