Businesses in manufacturing, engineering, and product development face increasing pressure to deliver innovative solutions while minimizing costs and maximizing efficiency. Desktop and large-scale 3D printing are a game-changing technology that redefines how businesses create, prototype, and produce. Be sure to take our 1-Min survey which will help gauge where you are at on your 3D Printing journey and get helpful insights on which solutions are best.

In this blog, we spotlight the incredible benefits of 3D printers designed for engineering-grade materials and highlight the power of advanced materials like PEEK, Onyx, Composite Carbon Fiber, PA-66, ABS, PLA, and Nexa3D’s resin options. Here’s how these technologies can transform your business in 2025 and beyond.

Mark Two – Continuous Fiber Composite Desktop Printer

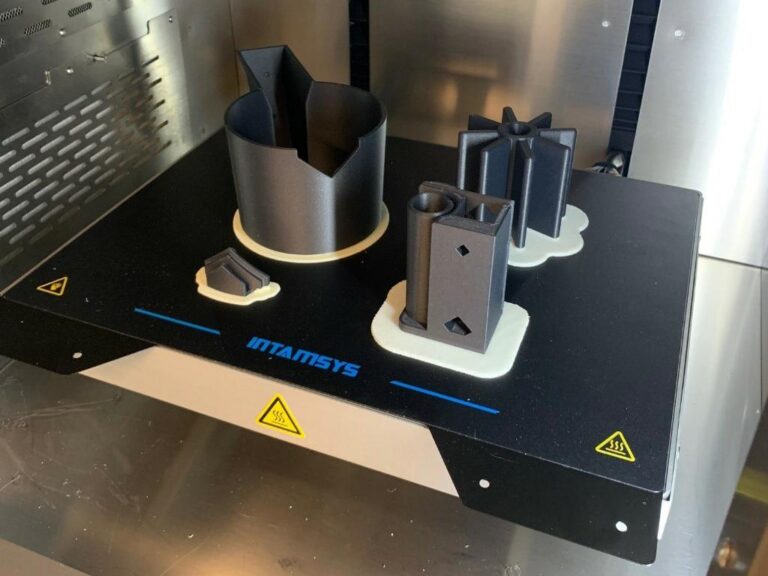

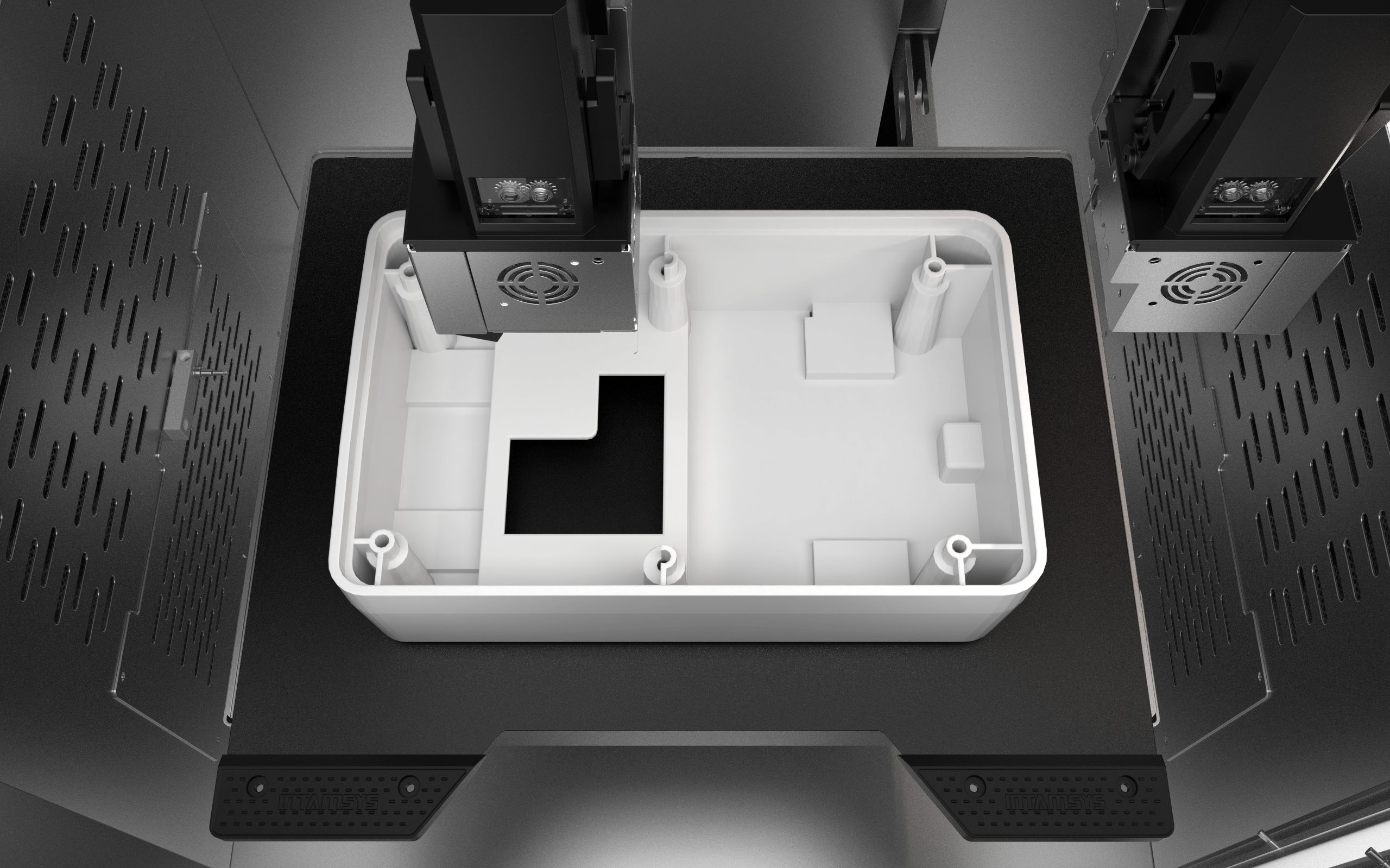

ALTRA280 – Reliable Manufacturing of Large Complex Parts

Why Desktop and Large-Scale 3D Printing Matters

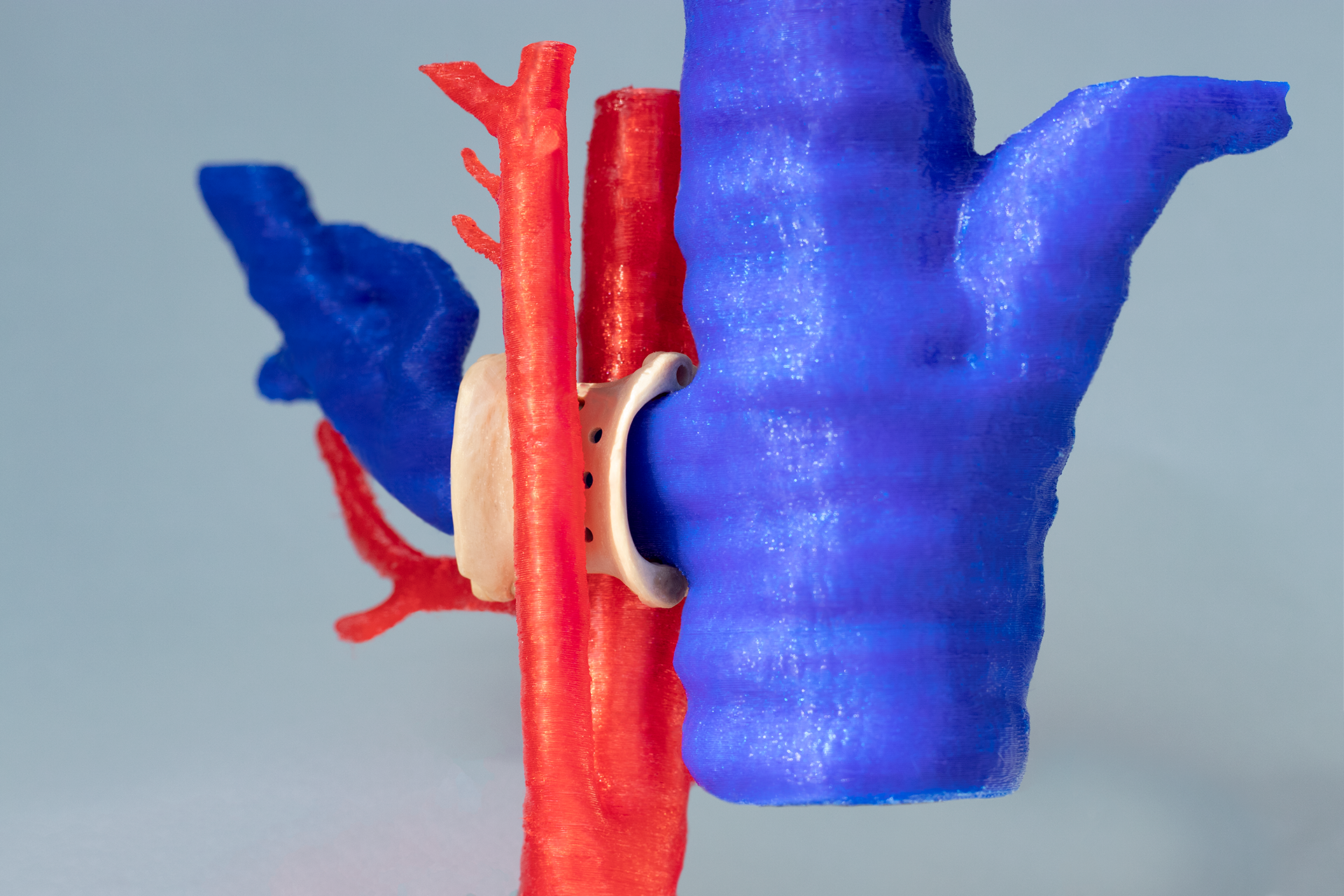

Desktop and large-scale 3D printers are no longer just for prototyping. With the capability to print reinforced and high-performance materials, these machines enable businesses of all sizes to create durable, functional parts suitable for end-use applications.

Whether you’re producing lightweight components or high-strength parts these printers offer unmatched versatility and cost-effectiveness. Industrial & professional 3D printers are built for efficiency and to save time. The choice between small and large printers depends on your facility’s available space and the size of the parts you need to produce.

Take our 1-min Buyer Qualification Survey!

How Getting the Right Printer Can Boost Profitability

- Lower Production Costs: 3D printing eliminates the need for expensive tooling and molds, reducing upfront costs and allowing for affordable low-volume production.

- Accelerated Time-to-Market: High-speed printers like Nexa3D XIP PRO or INTAMSYS 310NEO can produce parts in hours instead of weeks, helping businesses meet tight deadlines and adapt to market demands.

- Reduced Material Waste: Unlike traditional subtractive manufacturing, 3D printing uses only the material needed for the part, cutting waste and saving money.

- Customizable Solutions: Produce on-demand parts tailored to specific requirements, enabling businesses to offer highly personalized products.

- Increased Design Freedom: Complex geometries and lightweight designs are easier to achieve, giving engineers the flexibility to innovate.

Top Materials Driving Profitability in 2025

PEEK:

Onyx and Onyx-CF (Carbon Fiber):

-

- Combines the durability of nylon with the strength of carbon fiber reinforcement.

- Perfect for lightweight tooling, jigs, and fixtures with superior stiffness and reliability.

- Compatible Printers: Markforged Mark Two or Markforged X7

Pro HT

Composite Carbon Fiber Filaments PA66-CF, PA12-CF ):

-

- Provides unparalleled stiffness and tensile strength.

- Revolutionizes the production of structural parts in automotive, sporting, and consumer goods industries.

- Compatible Printers: Markforged Mark Two or Markforged X7, INTAMSYS FUNMATPRO 310NEO, PRO410, 610HT

PA-66 (Nylon):

ABS and PLA:

-

- Affordable, versatile materials for prototyping and light-duty parts.

- PLA’s ease of use and ABS’s toughness make them staples in product development.

- Compatability: All 3D Printers (FDM) have a type of ABS and/or PLA

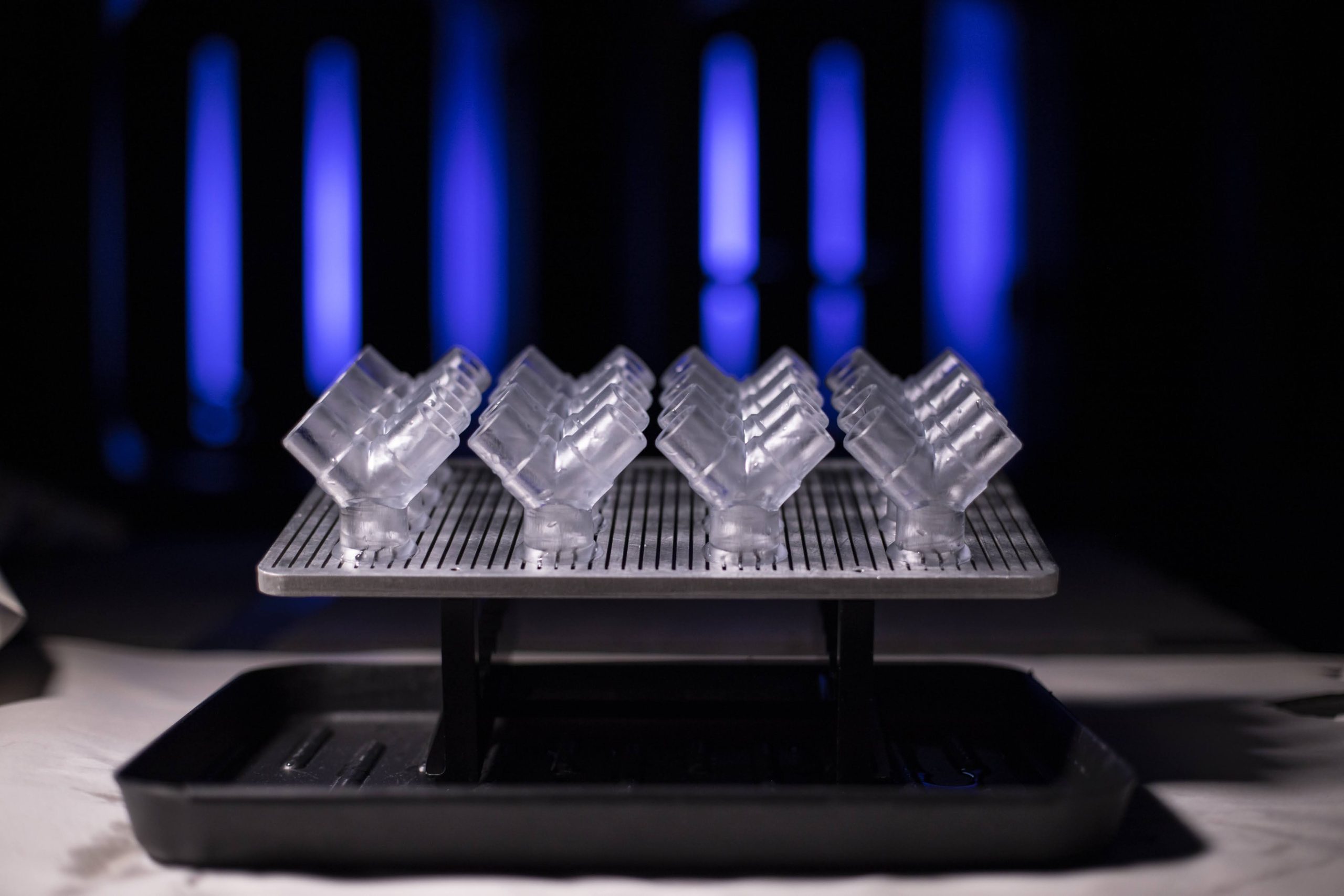

Nexa3D Resins:

-

- Delivers ultra-fast printing speeds with resins tailored for everything from precision prototypes to functional end-use parts.

- Expands capabilities in industries like healthcare, consumer goods, and electronics.

- Compatible Printers: Nexa3D XIP , XIP PRO

Real-World Applications

Aerospace & Defense: Lightweight, heat-resistant parts for fuel efficiency

Automotive: Durable components that reduce assembly time and cost.

Healthcare: Custom prosthetics and surgical tools with biocompatible materials.

Consumer Goods: Faster prototyping for new product launches.

Buyer Qualification Survey for Next-Gen 3D Printers

Take a quick 1-minute survey that provides input which helps us better understand general needs and create solutions that fit the job.

Get Started Today!

Ready to unlock the potential of engineering-grade and reinforced 3D printing materials? Contact us today to explore our solutions, schedule a demo, or request a quote. Let’s make 2025 your most productive and profitable year yet!