Understanding the materials you use is key to successful outcomes. Let’s break down two of the most popular FDM filaments: PLA and ABS.

NeoMetrix Is Here to Help- Choosing the right material that suits your parts and purpose is just the beginning. At NeoMetrix, we help you match your application to the perfect machine, material, and workflow—from concept through product. Need 3D printing services?- Contact us today for a quote!

Here’s some key insights on the widely used materials: PLA vs ABS

Quick Comparison: PLA vs. ABS

| Property | PLA | ABS |

|---|---|---|

| Ease of Use | Beginner-friendly | Requires enclosed, heated setup |

| Surface Finish | Smooth, glossy | Matte, great for post-processing |

| Strength | Moderate, brittle under stress | Durable, impact-resistant |

| Heat Resistance | ~60°C | ~105°C |

| Environmental Impact | Biodegradable, plant-based | Petroleum-based, recyclable |

| Common Applications | Prototypes, models, art, toys | Tools, housings, mechanical parts |

PLA and ABS are among the most commonly used materials in 3D printing, favored for their ease of use, affordability, and reliability in prototyping and basic functional parts. However, when your applications demand engineering-grade strength, high-temperature resistance, or specialized performance, PLA and ABS may fall short. That’s where NeoMetrix Technologies comes in. We offer advanced material solutions—including carbon fiber-reinforced, high-temp, and chemical-resistant filaments—alongside expert guidance to ensure the right fit for your application. If you’re ready to move beyond basic materials and into industrial-grade performance, contact us today to explore the best solution for your needs.

PLA: The Easy Choice for Prototyping & Aesthetics

Polylactic Acid (PLA) is a favorite for beginners and professionals alike. Its lower printing temperature, minimal warping, and eco-friendly composition make it a go-to for:

- Concept models

- Educational projects

- Art and decor

- Prototypes that don’t face mechanical stress

Perfect when design and speed matter more than toughness.

ABS: Built for Durability & Real-World Function

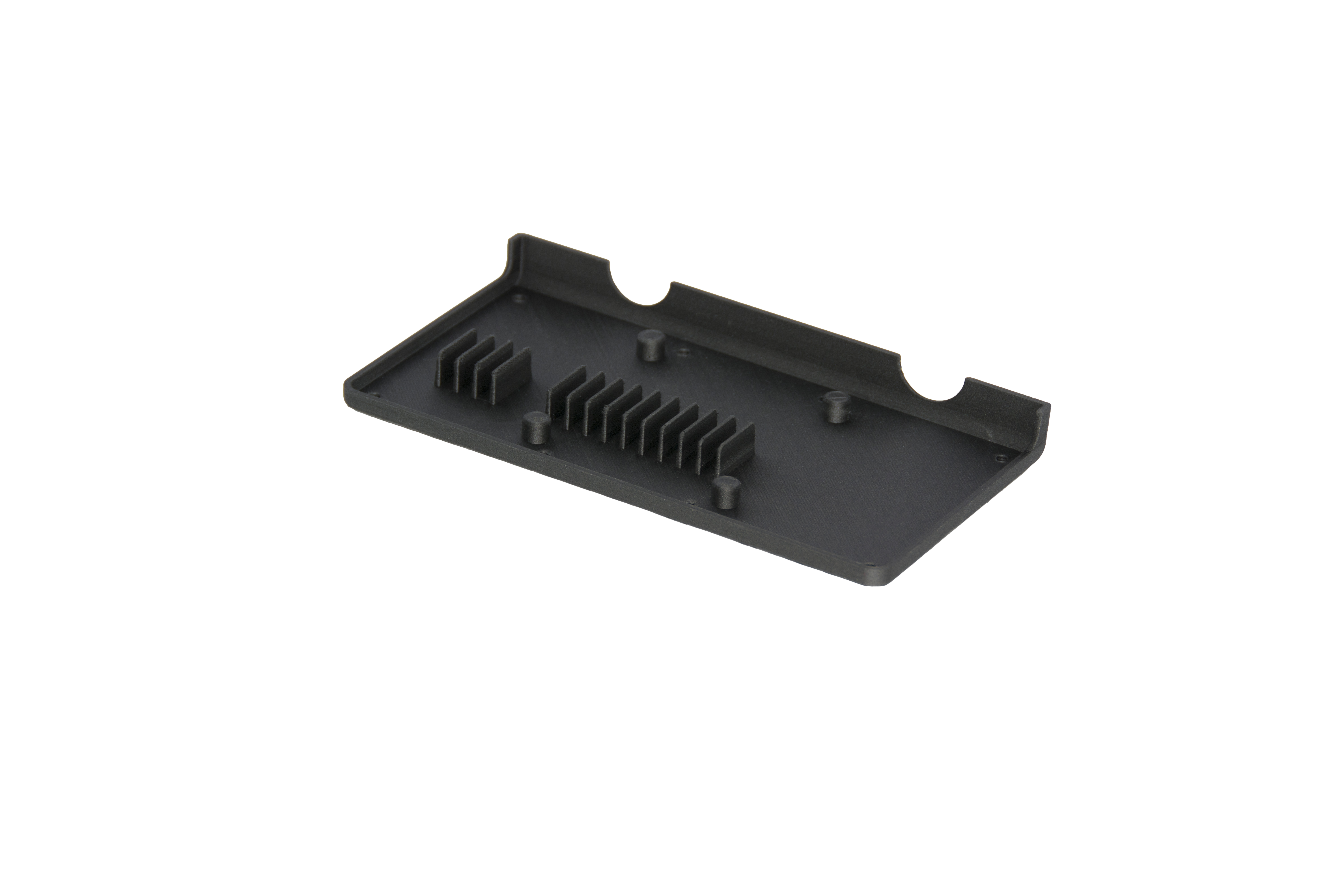

Acrylonitrile Butadiene Styrene (ABS) is a step up for those needing performance. Known for strength and thermal resistance, ABS is the right pick for:

- End-use parts

- Functional prototypes

- Jigs, fixtures, and tooling

- Automotive and electronics housings

It prints best with a heated bed and enclosed chamber but pays off in part longevity and post-processing flexibility.

PARTS THAT EXCEL – SATISFIED CLIENTS

“Dan and his team were amazing to work with, we had an interesting need to design a custom bracket to fit on a custom Android device and NeoMetrix handled the request quickly and got us a prototype in no time! I don’t know what we would have done if we didn’t find NeoMetrix, they are willing to work on small projects but after visiting their offices in Lake Mary, can obviously handle large projects too. Give them a chance if you need any help getting a 3D design created or printed, you won’t be disappointed.”

BigRep printers, available through NeoMetrix, support both PLA and ABS in large-format applications—ideal for engineering teams, product designers, and manufacturers looking to scale.

- Choose PLA if you want fast, clean prints for aesthetic or low-stress parts.

- Choose ABS if your parts need to survive wear, heat, or real-world use.

Experience the Future of Industrial 3D Technology at NeoMetrix’s Open House

for Manufacturers, Engineers, and Innovators!

DATE: Thursday,April 10th, 2025

TIME: 1:00PM – 5:00PM EST

LOCATION: 55 Skyline Dr #2700, Lake Mary, FL 32746

Get Started! – Schedule a 3D Printing Discovery Session

Ready to unleash innovation, optimize workflows, and stay ahead in the competitive landscape with NeoMetrix Technologies? Every top modern business deserves access to the transformative capabilities of 3D printing.

Schedule a FREE 3D Printing Discovery Session to see which solutions and equipment are best to suit your design and production challenges.

Your 3D Problems...SOLVED!

Original Artical: https://bigrep.com/posts/pla-vs-abs-which-is-better/