Additive manufacturing has offered open access to affordable manufacturing solutions and unparalleled reductions in the cost of low-volume high-mix manufacturing. Because of these combined possibilities, a wealth of personalized products have become available to the market from all sizes of businesses.

The affordability of large-format additive technology has even changed the way professionals are introduced to manufacturing processes, which now often begins during post-secondary education with in-house industrial 3D printers. Universities everywhere are integrating additive into their curriculums in a variety of disciplines that allow students to have hands-on experience with manufacturing technology before entering the workforce.

After Australia’s University of Technology Sydney (UTS) acquired a BigRep ONE large-format 3D printer for their fabrication lab, ProtoSpace, they were excited to flex their new additive muscles and create a publishable case study. The task was taken on by Dr. James Novak, at the time a postdoctoral researcher at UTS (now a Research Fellow in additive manufacturing at Deakin University) who set out to create a showcase-worthy design that would test the BigRep ONE’s capabilities and highlight its potential to produce highly customizable products.

Novak took personalization to the next level in his design, literally incorporating himself into the project by creating a stool from him and his wife’s fingerprints.

“It was designed when my wife and I got engaged and feature’s the ring fingerprint impressions from both of us,” said Novak. He noted the project was conceived in part because of the absolute individuality of a fingerprint, highlighting the unmatched level of personalization that additive manufacturing offers.

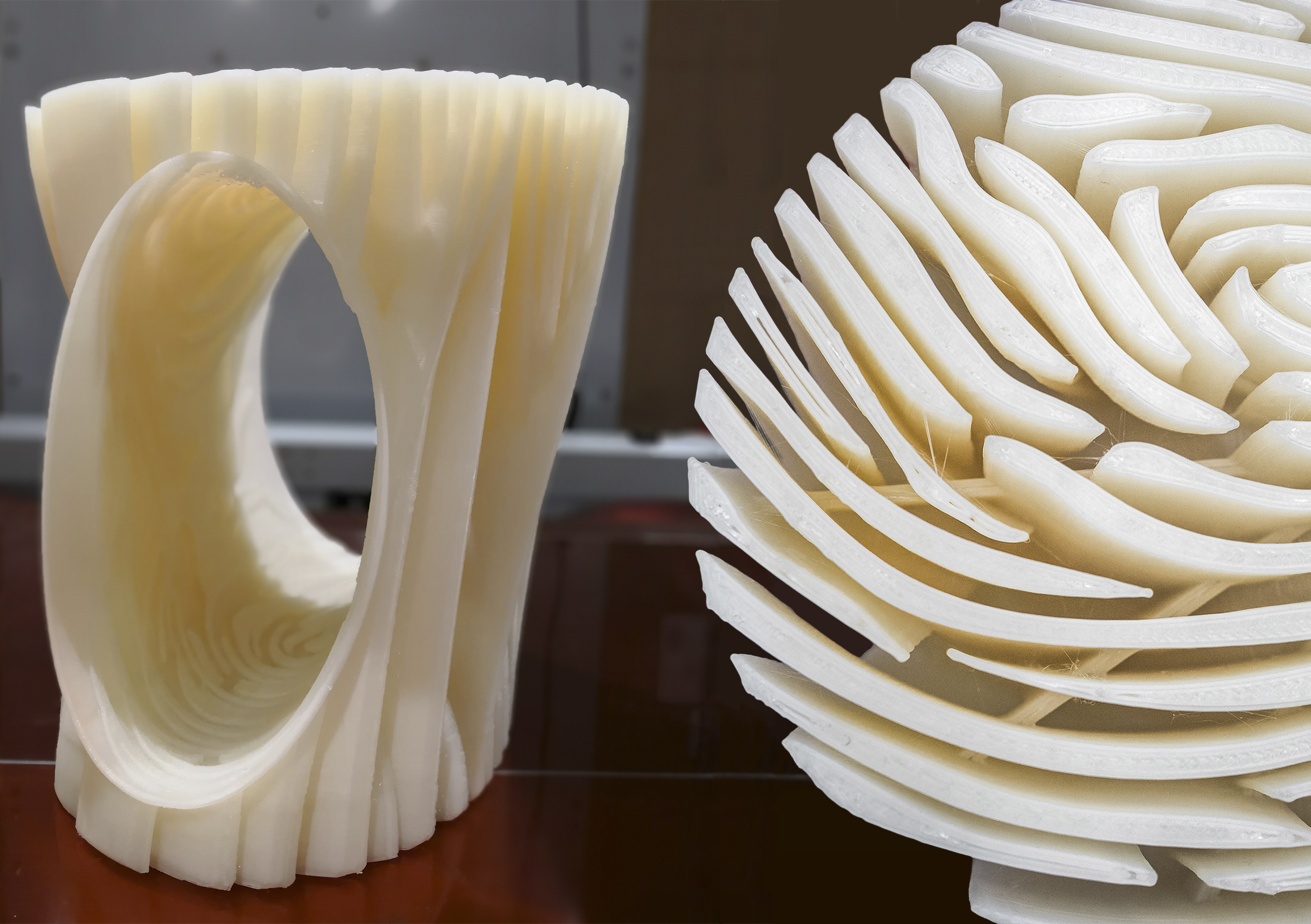

The highly-organic design connects the fingerprint ridges, weaving support through empty space before merging in the design’s open mid-section.

Novak explained, “as the fingerprints merge through the center of the design, an organic form emerges that can only be manufactured using 3D printing, and there is no support material needed.”

To simplify the printing process, it was decided to print the design with a support raft that ensured the first layers – which are otherwise unconnected – wouldn’t warp, but Novak noted that the same result could be accomplished with the right build platform adhesive.

The resulting design is an excellent example of the unique capabilities of 3D printing: an entirely personalized end-use product with a complex geometry that can only be produced with large-format additive manufacturing.

Novak’s stool is also demonstrative of large-format additive’s unmatched potential for lean manufacturing, allowing for the creation of highly customizable products in small batch production. Combined with accessible price points and transferable design skills, large-format additive clearly presents an enviable solution at all levels of business.

Using only a small portion of the BigRep ONE’s build volume, multiple independent designs like Novak’s stool easily be completed in the same production run, and production speed can be easily increased by taking advantage of large-format’s scalability – adding to existing machines by opting for performance enhancements like a second extruder to run in tandem.

With this unparalleled flexibility and potential for customization, large-format additive presents an accessible, future-ready manufacturing solution.